- Wenling zhejiang China

- [email protected]

- +86 18958695512

- Home

- PRODUCTS

- POSITIONER

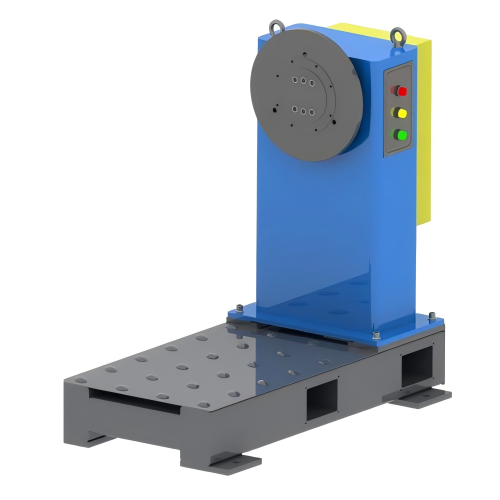

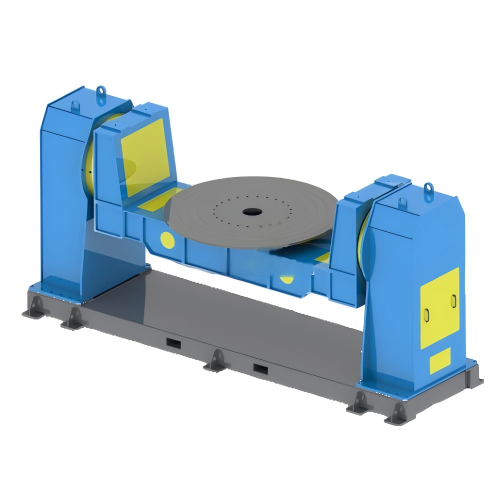

- Robot Positioner High quality 2 Dual Axis U-Shaped FlipTable Welding Turntable

Robot Positioner High quality 2 Dual Axis U-Shaped FlipTable

Our high-performance robot positioner features an innovative U-shaped flip table design engineered for seamless integration with welding robot positioner systems. This positioner table offers dual-axis servo-controlled movement with 360° continuous rotation and ±180° tilting capability, providing complete workpiece accessibility for complex welding applications

Applications:

Automotive component welding

Heavy equipment fabrication

Pressure vessel manufacturing

Aerospace structural welding

SC-TYPE U-3000/5000

CHINA

30DAYS

T/T

NINGBO/SHANGHAI CHINA

| Axis Number | 6 |

|---|---|

| Payload | 800/1000kg |

| Repeat Positioning | ±0.15mm |

Dual Axis U-Shaped Industrial Welding Robot Positioner – The Ultimate Solution for Automated Welding Applications

As a leading manufacturer of industrial automation equipment, we proudly present our Dual Axis U-Shaped Industrial Welding Robot Positioner, designed to revolutionize precision welding operations. This state-of-the-art robot positioner features a robust flip table design, ensuring optimal workpiece positioning for welding robots across various industries. Whether used in automotive manufacturing, heavy machinery fabrication, or aerospace welding, our welding robot positioner delivers unmatched stability, precision, and efficiency.

Key Features & Advantages

1. Dual-Axis Servo-Driven Motion for Maximum Flexibility

Our positioner table is engineered with dual-axis servo control, allowing:

360° continuous rotation for complete workpiece accessibility

±180° tilting capability for multi-angle welding

High-torque servo motors ensuring smooth, vibration-free movement

Programmable positioning (±0.02° accuracy) for repeatable welds

2. Heavy-Duty U-Shaped Flip Table Design

Sturdy steel construction with reinforced support beams for load capacities up to 500kg

Optimized U-shaped frame for easy robot arm access and minimal interference

Quick-clamping system for fast workpiece changes

Anti-sparking coating for enhanced safety in welding environments

3. Seamless Integration with Welding Robots

Our welding robot positioner is compatible with:

Fanuc, KUKA, ABB, Yaskawa, and other major robot brands

PLC & CNC control systems for automated production lines

Real-time synchronization with robotic welding paths

Tool Center Point (TCP) tracking for precision welding

4. Smart Automation & User-Friendly Controls

Touchscreen HMI for easy programming and adjustments

Pre-set welding programs for common applications

Collision detection & emergency stop for operator safety

IoT-enabled models available for Industry 4.0 integration

Our robot positioner is ideal for:

Automotive welding (chassis, exhaust systems, suspension components)

Heavy machinery fabrication (excavator arms, crane booms)

Aerospace & defense (aircraft frames, engine mounts)

Pipe & pressure vessel welding (large-diameter circumferential seams)

General metal fabrication (jigs, fixtures, structural welding)

Why Choose Our Welding Robot Positioner?

Higher Payload Capacity – More stable than standard L-type positioners

Faster Cycle Times – Optimized for high-efficiency production

Lower Maintenance – Sealed bearings & long-life gearboxes

Customizable Options – Tailored to your specific welding needs

Competitive Advantages

30% More Cost-Effective than European equivalents

45-60 Day Lead Time (faster than industry average)

5-Year Warranty on critical components

Global Technical Support & spare parts availability

Competitive Advantages:

Higher payload-to-weight ratio than industry standard

Lower maintenance requirements with sealed gear units

Smoother motion control with advanced servo algorithms

Easy integration with existing automation systems

On-site installation support

Operator training programs

Annual maintenance contracts

Technical documentation (3D models, manuals)

Upgrade Your Welding Automation Today!

Whether you need a single welding robot positioner or a fully integrated automated welding cell, our Dual Axis U-Shaped Positioner delivers precision, durability, and value.

Our welding robot positioner combines German engineering precision with competitive Chinese manufacturing – the ideal solution for automated welding cells.

Whether you need a single welding robot positioner or a fully integrated automated welding cell, our Dual Axis U-Shaped Positioner delivers precision, durability, and value.

SHENCHI ROBOT CO.,LTD provide different industrial robot with automation solutions . we support industrial robots including welding, painting, handling, palletizing, bending and polishing, welcome to contact us.

Shenchi robot ,More smart more simple

© Shenchi Company All right reserved.