- Wenling zhejiang China

- [email protected]

- +86 18958695512

- Home

- PRODUCTS

- INDUSTRIAL ROBOT

- OTHER APPLICATIONS ROBOT

- CNC Robot OEM Custom Industrial Intelligent Fast robot

CNC Robot OEM Custom Industrial Intelligent Fast robot

We specialize in high-performance CNC Robotic Arms designed for machining, welding, palletizing, painting, and material handling. Our CNC Robots deliver German engineering precision at Chinese manufacturing costs, trusted by 500+ global manufacturers for their reliability, accuracy, and affordability.

Applications

• CNC machine tending (lathes/mills)

• Automotive welding & assembly

• Palletizing & packaging

• Spray painting & coating

Precision CNC Robotic Arms – Your Smart Manufacturing Solution

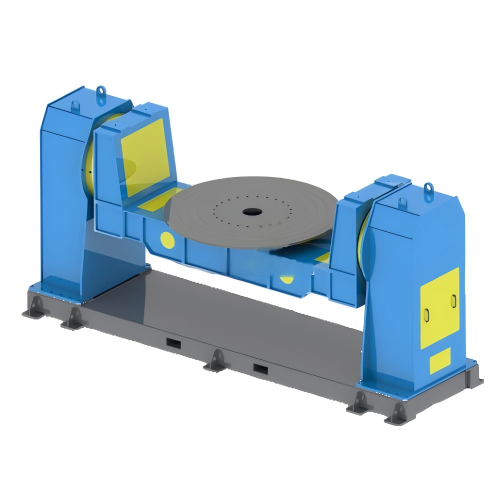

SC-CH1717

CHINA

30DAYS

T/T

NINGBO/SHANGHAI CHINA

High-Performance CNC Robotic Arms for Precision Manufacturing

We specialize in CNC Robotic Arms designed to revolutionize machining, welding, palletizing, painting, and material handling operations. Our CNC Robots combine German engineering precision with Chinese manufacturing efficiency, delivering unmatched accuracy, durability, and cost-effectiveness for factories worldwide.

With over [X] years of industry experience and [X,XXX] units installed globally, we have become a trusted partner for manufacturers seeking to automate production, reduce labor costs, and improve quality control. Whether you need precision machining assistance, high-speed welding, or automated material transfer, our CNC Machining Service Robots provide flexible, high-performance solutions tailored to your specific needs.

Why Choose Our CNC Robotic Arms?

1. Multi-Application Capability

CNC Machine Tending – Automated loading/unloading of lathes, mills

Precision Welding – Arc, spot, and laser welding applications

Palletizing – Up to 500kg payload capacity

Spray Painting – Uniform coating with ±0.1mm accuracy

Material Handling – Seamless integration with conveyors

2. Superior Technical Specifications

6-axis articulated design for maximum flexibility

±0.02mm repeatability for machining precision

IP67 protection for harsh industrial environments

50,000-hour MTBF (Mean Time Between Failures)

3. Smart Control & Integration

Compatible with Fanuc, Siemens, Mitsubishi CNCs

PLC & HMI interface for easy programming

Vision system & force sensor compatibility

IoT-ready for Industry 4.0 connectivity

4. Cost-Effective Manufacturing

30-50% lower cost than European/Japanese brands

60-day standard lead time

Low maintenance design with long service life

1. CNC Machine Tending

Automated loading/unloading for lathes and mills

24/7 operation with consistent quality

Quick changeover between different parts

2. Precision Welding

Arc welding for structural components

Spot welding in automotive production

Laser welding for delicate electronics

3. Palletizing & Material Handling

Box/bag stacking up to 500kg

Conveyor belt transfer systems

AGV (Automated Guided Vehicle) integration

4. Spray Painting & Coating

Automotive body painting

Industrial powder coating

Anti-corrosion sealing

Competitive Advantages

Higher payload capacity than similar-priced competitors

More stable operation with vibration-dampening technology

Easier integration with existing CNC machines

Longer service life (50,000+ cycles MTBF)

Why Global Buyers Trust Us

ISO 9001 & CE certified manufacturing

5-year warranty on critical components

24/7 technical support

Local service partners in 15+ countries

Customization Options

We offer tailored solutions including:

Special end-effectors for unique applications

Custom reach and payload configurations

Automated product detection systems

Cleanroom-compatible models

Technical Advantages

6-axis flexibility for complex tasks

IP67 protection for harsh environments

50,000-hour lifespan with minimal maintenance

30% faster cycle times vs manual work

Product characteristics

The main body adopts high flexibility robot specific cables

Mounting dimension internally.

Flexible selection of homework, includingground installation, side installation, and inverted installation scenarios.

Mounting dimensions of base Flange dimensions of end welding gun

Four axis, five axis, and six axis harmonic high-precision reducers

are suitable for high-precision welding and handling

markets, such as laser welding robots, laser cutting robots

Upgrade Your Production Line Today!

Our CNC Robotic Arms represent the perfect balance of quality, performance, and value – helping manufacturers worldwide enhance their productivity while reducing operational costs.

SHENCHI ROBOT CO.,LTD provide different industrial robot with automation solutions . we support industrial robots including welding, painting, handling, palletizing, bending and polishing, welcome to contact us.

Shenchi robot ,More smart more simple

© Shenchi Company All right reserved.