- Wenling zhejiang China

- [email protected]

- +86 18958695512

- Home

- PRODUCTS

- INDUSTRIAL ROBOT

- OTHER APPLICATIONS ROBOT

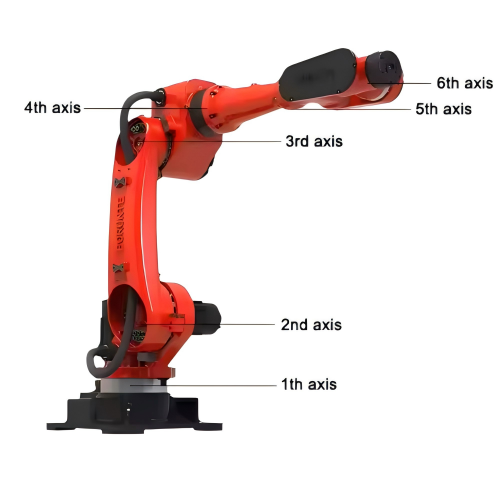

- Articulated Robot high quality 6 axis industrial robot arm

Articulated Robot high quality 6 axis industrial robot arm

As manufacturing demands grow increasingly complex, our Articulated Robot emerges as the ultimate automation solution for precision Punching Machine and Pressure Casting applications. This High Precision Robot delivers unmatched performance, combining industrial-grade durability with cutting-edge technology to transform your production line.

Industry-Proven Applications:

Precision metal stamping and hole punching

Die casting machine tending with heat-resistant capabilities

Automated material handling for punching processes

Quality inspection integrated into casting operations

SC-BR1820

CHINA

30DAYS

T/T

NINGBO/SHANGHAI CHINA

Articulated Robot: The Ultimate Automation Solution for Punching and Pressure Casting Applications

In today’s competitive manufacturing landscape, precision, efficiency, and reliability are paramount for maintaining a competitive edge. Our state-of-the-art Articulated Robot represents the pinnacle of industrial automation technology, specifically engineered to excel in demanding applications such as Punching Machine operations and Pressure Casting processes. As a leading provider of Robotic Project Works Solutions, we deliver cutting-edge automation that transforms production lines across multiple industries.

This comprehensive guide explores how our Industrial Robot Arm revolutionizes manufacturing processes through its unmatched precision, robust construction, and intelligent automation capabilities. Whether you’re in automotive manufacturing, metal fabrication, or precision casting, our High Precision Robot is designed to elevate your production efficiency while reducing operational costs.

Articulated Robot Technical Specifications & Key Features

1. Precision Engineering for Demanding Applications

6-axis articulated design for maximum flexibility in complex movements

±0.02mm repeatability ensuring consistent, high-accuracy operations

Advanced servo control system for smooth, vibration-free motion

IP67 rated protection against dust, liquids, and harsh industrial environments

2. Robust Performance for Heavy-Duty Applications

Payload capacities ranging from 5kg to 50kg to suit various production needs

High-speed operation with optimized cycle times for punching and casting processes

Shock-resistant construction to withstand the rigors of punching machine operations

Heat-resistant materials for reliable performance in pressure casting environments

3. Smart Automation Technologies

Integrated force sensing for adaptive pressure control in casting applications

Real-time position tracking with advanced encoder systems

Collision detection and automatic recovery features

Programmable logic controller (PLC) integration for seamless production line coordination

4. Ergonomic Design & Integration

Compact footprint saves valuable floor space in production facilities

Quick-change end-effector system for rapid tooling switching

Pre-installed safety systems including emergency stop and speed monitoring

Energy-efficient operation with regenerative braking technology

Industry-Specific Applications

1. Punching Machine Automation

Precision metal stamping with consistent force application

High-speed hole punching for sheet metal fabrication

Progressive die operations with perfect alignment

Automated material handling before and after punching processes

2. Pressure Casting Solutions

Die casting machine tending with precise part placement

Molten metal handling with heat-resistant end effectors

Casting trimming and finishing operations

Quality inspection integrated into the casting process

3. Additional Industrial Applications

Automotive component manufacturing

Aerospace parts production

Electronics enclosure fabrication

Industrial equipment assembly

System Integration Options

1. Complete Punching Machine Cell

Turnkey Robotic Project Works Solutions for punching applications

Includes robot, tool changers, material handling systems, and safety fencing

Pre-programmed routines for common punching operations

Force monitoring for quality assurance

2. Pressure Casting Automation Package

Specialized Industrial Robot Arm configuration for foundry environments

Heat shielding and cooling systems

Integrated vision systems for casting inspection

Automated ladle handling options

3. Flexible Manufacturing Solutions

Multi-robot coordinated workcells

Automated part transfer between processes

Smart factory connectivity (Industry 4.0 ready)

Remote monitoring and diagnostics

Competitive Advantages

1. Unmatched Precision & Quality

Consistent operation eliminates human error

Micro-adjustment capability for perfect part alignment

Data logging for quality traceability

Reduced scrap rates and material waste

2. Productivity Enhancements

24/7 operation capability

30-50% faster than manual operations

Simultaneous multi-process operations

Quick changeover between production runs

3. Cost Savings & ROI

Up to 60% reduction in labor costs

Lower energy consumption than conventional systems

Reduced tooling wear through precise operation

Minimal maintenance requirements

4. Future-Proof Technology

Software upgradable for new applications

Modular design for easy expansion

IoT connectivity for predictive maintenance

Compatibility with emerging industry standards

Technical Support & Service

Our global support network ensures your High Precision Robot operates at peak performance:

On-site installation and commissioning

Comprehensive operator training programs

Preventive maintenance contracts

Remote diagnostics and troubleshooting

Dedicated spare parts inventory

Case Studies & Success Stories

Case Study 1: Automotive Stamping Plant

Implementation of our Articulated Robot in a punching application achieved:

40% increase in daily output

Defect rate reduction from 3% to 0.1%

ROI achieved in just 7 months

Case Study 2: Aluminum Casting Foundry

Integration of our Industrial Robot Arm for pressure casting resulted in:

50% reduction in labor costs

35% decrease in material waste

Improved worker safety by removing personnel from hazardous areas

Conclusion: Transform Your Production Today

Our Articulated Robot represents the perfect fusion of precision, power, and flexibility for modern manufacturing. As specialists in Robotic Project Works Solutions, we provide complete automation packages tailored to your specific needs in punching and pressure casting applications.

With its high precision capabilities, robust construction, and intelligent automation features, this Industrial Robot Arm delivers measurable improvements in quality, productivity, and profitability across numerous industries.

Take the first step toward manufacturing excellence – contact our automation specialists today for a personalized consultation and demonstration.

SHENCHI ROBOT CO.,LTD provide different industrial robot with automation solutions . we support industrial robots including welding, painting, handling, palletizing, bending and polishing, welcome to contact us.

Shenchi robot ,More smart more simple

© Shenchi Company All right reserved.