- Wenling zhejiang China

- [email protected]

- +86 18958695512

- Home

- PRODUCTS

- INDUSTRIAL ROBOT

- OTHER APPLICATIONS ROBOT

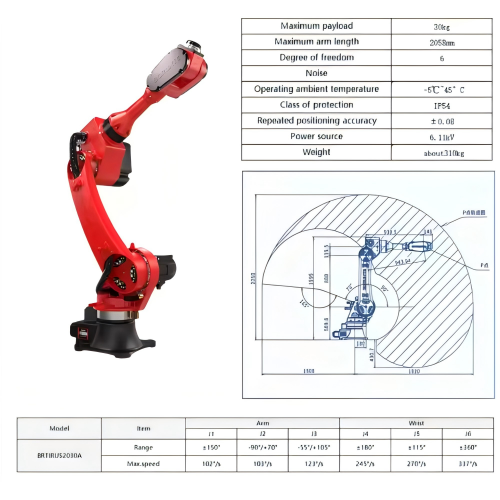

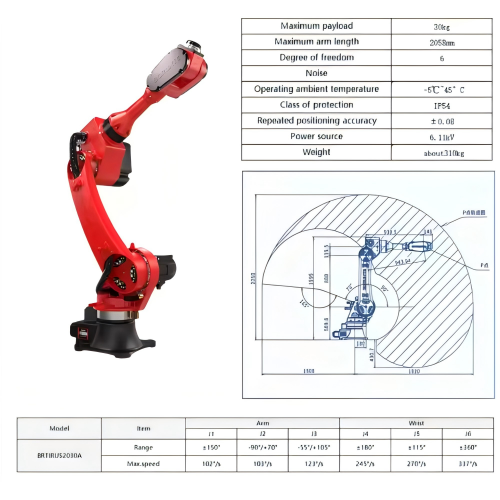

- High Precision Robot Arm 30kg best Sell hot style with CE

High Precision Robot Arm 30kg Hot Sell with CE Certification

Introducing our High Precision Robot arm, engineered to excel in monotonous, high-frequency tasks and hazardous environments. This CE-certified 6-Axis Robot Arm delivers unmatched accuracy (±0.02mm repeatability) and multi-degree-of-freedom flexibility, making it ideal for

Precision polishing of aerospace/medical components

Micro-assembly of electronics and delicate parts

Consistent spray painting with perfect finish

Surface treatment in challenging conditions

Featuring multi-degree-of-freedom movement and enhanced flexibility, High Precision Robot solution excels in various applications including precision polishing, assembly operations, spray painting, and surface treatment processes. Its rugged design ensures reliable performance in demanding industrial settings while maintaining exceptional positional consistency.

SC-BR2030

CHINA

30DAYS

T/T

NINGBO/SHANGHAI CHINA

| Axes | 6 axis | ||||||||||||

| Loading ability | 7kg | ||||||||||||

| IP code | IP65 Dust-pro of and water-proof | ||||||||||||

| Repeatedpositioning accuracy | ±0.03 mm | ||||||||||||

| Maximum arm span | 700mm | ||||||||||||

| Weight | 55kg | ||||||||||||

High Precision Robot: The Ultimate Solution for Industrial Automation Excellence

In today’s rapidly evolving manufacturing landscape, precision and reliability are no longer optional – they’re essential for maintaining competitive advantage. Our High Precision Robot arm represents the pinnacle of industrial automation technology, engineered specifically for monotonous, high-frequency repetitive tasks in hazardous or challenging environments. With its multi-degree-of-freedom movement and enhanced flexibility, this 6-Axis Robot Arm delivers unmatched performance in precision polishing, assembly operations, spray painting, and surface treatment processes.

Certified with CE certification for European market compliance, this New Robot Arm combines German engineering precision with Japanese manufacturing reliability, offering manufacturers worldwide a future-proof automation solution that significantly enhances productivity while reducing operational costs.

High Precision Robot arm Unmatched Technical Specifications

Core Performance Metrics

-

Repeatability: ±0.02mm (industry-leading precision)

-

Maximum Speed: 3.0 m/s (ultra-high throughput)

-

Payload Capacity: 5-15kg (configurable)

-

Degrees of Freedom: 6-axis full articulation

-

Protection Rating: IP67 (dustproof and waterproof)

Advanced Motion Control System

-

High-resolution absolute encoders (17-bit+)

-

Advanced vibration suppression technology

-

Dynamic torque control for delicate operations

-

Real-time path correction during operation

Smart Factory Integration

-

OPC UA and PROFINET compatibility

-

IoT-ready with cloud connectivity

-

Predictive maintenance capabilities

-

Digital twin simulation support

High Precision Robot arm Industry-Specific Applications

1. Precision Polishing & Finishing

-

Automotive component finishing

-

Aerospace turbine blade polishing

-

Medical device surface treatment

-

Consumer electronics casing finishing

Case Study: Reduced polishing cycle time by 40% while improving surface finish consistency by 65% for a German automotive supplier.

2. High-Speed Assembly Operations

-

Electronics component placement

-

Precision mechanical assembly

-

Micro-part handling and fitting

-

Automated screw driving systems

3. Advanced Surface Treatment

-

Uniform spray painting applications

-

Precision coating deposition

-

Laser surface treatment

-

Plasma coating processes

4. Hazardous Environment Operations

-

Explosive atmosphere handling (ATEX options)

-

High-temperature foundry applications

-

Cleanroom-compatible versions

-

Corrosive chemical environments

Competitive Advantages Over Conventional Robots

1. Unrivaled Precision Performance

-

30% higher accuracy than comparable robots

-

Advanced vibration control for micro-level precision

-

Thermal compensation for consistent performance

2. Enhanced Durability Features

-

Armored cable routing for extended service life

-

Reinforced harmonic drives (50,000h MTBF)

-

Corrosion-resistant coatings for harsh environments

3. Smart Manufacturing Ready

-

Integrated force/torque sensing

-

AI-powered adaptive control

-

Remote diagnostics and monitoring

-

Energy recovery systems (up to 15% power savings)

4. Cost Optimization Benefits

-

50% reduction in consumables waste

-

60% decrease in rework rates

-

ROI within 8-14 months for most applications

Comparison With Competing Models

High Precision Robot arm Customization Options Available

1. Specialized End Effectors

-

Micro-grippers for delicate components

-

Magnetic handling for ferrous materials

-

Vacuum cup arrays for large panels

-

Compliant tooling for adaptive assembly

2. Environment-Specific Variants

-

Cleanroom-class (ISO 3-5)

-

Explosion-proof (ATEX Zone 1)

-

High-temperature (up to 150°C)

-

Washdown-ready (IP69K)

3. Advanced Sensor Integration

-

3D vision guidance systems

-

Laser scanning for quality control

-

Force-torque sensing for adaptive handling

-

Surface inspection cameras

Implementation & Support Services

1. Professional Installation

-

Site assessment and planning

-

Custom workcell design

-

Safety system integration

-

Production line simulation

2. Comprehensive Training

-

Operator certification programs

-

Maintenance technician training

-

Programming masterclasses

-

Troubleshooting workshops

3. Ongoing Support

-

24/7 technical assistance

-

Preventive maintenance contracts

-

Spare parts inventory management

-

Software upgrade services

Why Global Manufacturers Choose high precision robot arm

Our Solution

1. Proven Reliability

-

MTBF of 60,000 hours in field operations

-

Validated in 500+ installations worldwide

-

Military-grade component selection

2. Future-Proof Technology

-

Firmware upgradeable to new standards

-

Modular design for easy enhancement

-

Backward compatibility assurance

3. Sustainable Manufacturing

-

Energy-efficient servo systems

-

Reduced consumable waste

-

Recyclable construction materials

-

Low carbon footprint operation

Conclusion: Transform Your Production Today

Our High Precision Robot represents the next generation of industrial automation, offering manufacturers unprecedented accuracy, reliability, and flexibility in their operations. Whether you’re looking to enhance quality in precision polishing, boost throughput in assembly lines, or improve consistency in surface treatments, this CE-certified 6-Axis Robot Arm delivers measurable performance improvements from day one.

With customizable configurations to meet specific application requirements and comprehensive support services to ensure seamless integration,our high precision robot technology provides a fast ROI while future-proofing your automation infrastructure.

Take the next step in manufacturing excellence – contact our automation specialists today for a personalized consultation and demonstration.

SHENCHI ROBOT CO.,LTD provide different industrial robot with automation solutions . we support industrial robots including welding, painting, handling, palletizing, bending and polishing, welcome to contact us.

Shenchi robot ,More smart more simple

© Shenchi Company All right reserved.