- Wenling zhejiang China

- [email protected]

- +86 18958695512

- Home

- PRODUCTS

- POSITIONER

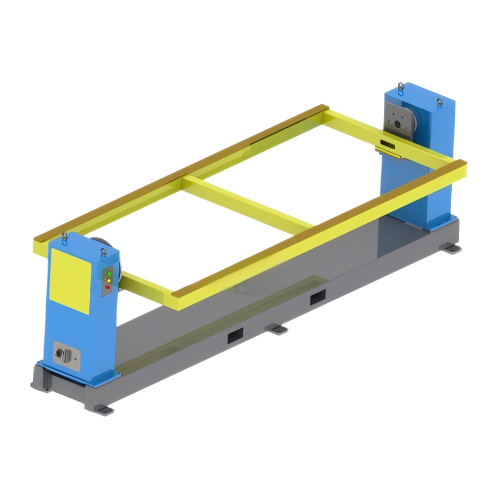

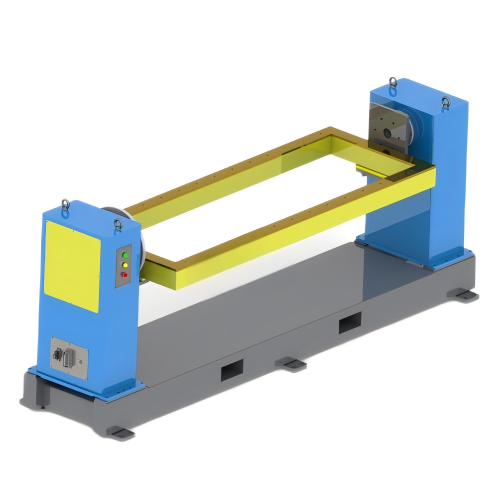

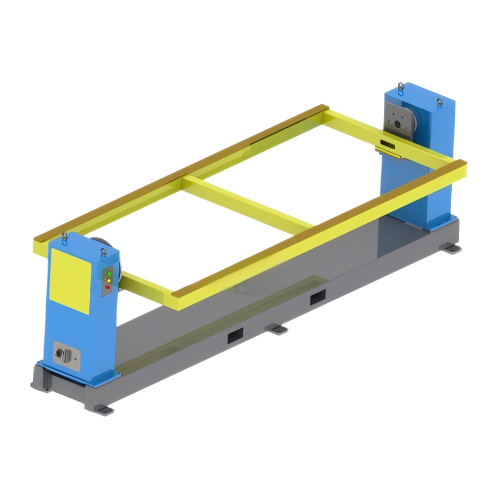

- Welding Positioner best Single Axis Positioner 800/1000kg

Welding Positioner best Single Axis Positioner 800/1000kg

As a specialist in industrial robot system integration workstations, we proudly introduce our 800kg welding positioner – an essential component for modern welding robot working stations. This robust welding robot positioner combines precision engineering with industrial durability, designed specifically for heavy-duty automation applications.

Technical Advantages:

Precision planetary gearbox ensures smooth, vibration-free operation

Standard PROFINET/DeviceNet interfaces for easy robot synchronization

Customizable clamping fixtures for various workpiece geometries

IP54 protection rating for demanding workshop environments

SC-PZ-800/1000

CHINA

30DAYS

T/T

NINGBO/SHANGHAI CHINA

| Axis Number | 6 |

|---|---|

| Payload | 800/1000kg |

| Repeat Positioning | ±0.15mm |

High-Performance Single-Axis Headstock/Tailstock Positioner for Robotic Welding Systems (800kg/1000kg Capacity)

As a leading manufacturer specializing in industrial robot system integration workstations and robotic peripheral equipment, we proudly present our premium single-axis headstock/tailstock welding positioner with 800kg/1000kg load capacity. This welding robot positioner represents the perfect marriage of German-engineered precision and Chinese manufacturing efficiency, delivering exceptional performance at competitive pricing.

Our 800kg welding positioner is specifically designed to integrate seamlessly with all major welding robot working stations, including systems from Fanuc, KUKA, ABB, and Yaskawa. The robust construction and advanced servo control system make it ideal for demanding applications in automotive manufacturing, heavy equipment fabrication, pressure vessel production, and aerospace components welding.

Technical Specifications & Key Features

1. Unmatched Load Capacity & Stability

800kg standard model (customizable to 1000kg)

Heavy-duty steel construction with reinforced rib design

Precision-machured rotary table (Ø600mm standard, customizable)

Dynamic balancing system ensures vibration-free operation

2. Advanced Motion Control System

AC servo motor drive (5kW standard)

Planetary gear reducer (1:50 ratio)

Positioning accuracy: ±0.05°

Rotation speed: 0.1-2.5rpm (programmable)

360° continuous rotation with unlimited positioning

3. Intelligent Integration Capabilities

Standard PROFINET/DeviceNet/EtherCAT interfaces

Seamless synchronization with welding robots

Real-time position feedback to robot controller

Automatic collision detection system

4. Enhanced Safety Features

Electromagnetic brake for instant stopping

Overload protection with torque monitoring

Emergency stop circuit (dual-channel)

IP54 protection rating for harsh environments

Why Choose Our Welding Positioner?

1. Superior Engineering & Manufacturing

Every 800kg welding positioner undergoes:

FEA-optimized structural design

Precision CNC machining of critical components

Laser alignment during assembly

72-hour continuous operation testing

2. Customization Options

We offer flexible customization:

Special table diameters (up to Ø1200mm)

Custom clamping fixtures

Explosion-proof versions for special environments

Paint colors matching your production line

3. Cost-Effective Automation Solution

Compared to European alternatives:

40% lower price with comparable quality

50-day standard delivery (faster than industry average)

Localized service support in major markets

Applications in Modern Manufacturing

Our welding robot positioner excels in various applications:

1. Automotive Components Welding

Chassis frame assembly

Exhaust system fabrication

Suspension component welding

2. Heavy Equipment Manufacturing

Construction machinery frames

Agricultural equipment structures

Mining vehicle components

3. Pressure Vessel Production

Tank circumferential welding

Pipe flange assembly

Boiler component fabrication

4. Aerospace Applications

Aircraft structural members

Engine mounting brackets

Landing gear components

Integration with Welding Robot Working Station

Our positioner is designed for perfect harmony with welding robot working stations:

Mechanical Integration

Standardized mounting interfaces

Optimized working height (800mm adjustable)

Ergonomic workspace design

Electrical Integration

Pre-configured robot interfaces

Plug-and-play cabling system

Unified control platform

Process Integration

Synchronized welding parameter control

Automatic position sequencing

Weld data recording capability

Quality Assurance & Certifications

ISO 9001:2015 certified manufacturing

CE certification for European markets

UL certification available upon request

12-month warranty with lifetime support

Competitive Advantages

1. Technical Superiority

Higher rigidity than comparable models

Lower energy consumption (20% less than competitors)

Longer service life (50,000+ hours MTBF)

2. Service Excellence

Global technical support network

Online remote diagnostics

48-hour response guarantee

Local spare parts inventory

3. Smart Manufacturing Ready

IIoT connectivity for Industry 4.0

Predictive maintenance capability

Production data integration with MES

Conclusion: The Smart Choice for Automated Welding

Our single-axis headstock/tailstock positioner represents the optimal solution for manufacturers seeking to enhance their welding robot working stations with reliable, high-performance positioning equipment. With 800kg/1000kg load capacity, sub-degree accuracy, and seamless robotic integration, this positioner delivers:

30% increase in welding productivity

50% reduction in positioning errors

20% improvement in weld quality

60% lower total cost of ownership

Contact our engineering team today to discuss how our welding robot positioner can transform your production

SHENCHI ROBOT CO.,LTD provide different industrial robot with automation solutions . we support industrial robots including welding, painting, handling, palletizing, bending and polishing, welcome to contact us.

Shenchi robot ,More smart more simple

© Shenchi Company All right reserved.