- ونلينغ تشجيانغ الصين

- [email protected]

- +86 18958695512

- بيت

- منتجات

- روبوت صناعي

- روبوت التكديس

- الصفحات

- روبوت التكديس على المنصات، حمولة 800 كجم، تسليم سريع، ذراع التكديس على المنصات

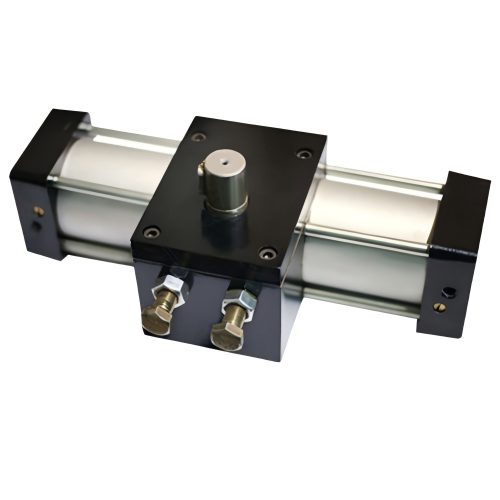

روبوت التكديس على المنصات، حمولة 800 كجم، تسليم سريع، ذراع التكديس على المنصات

حمولة 800 كجم، مسافة الوصول 3159 مم

روبوت ضخم لتكديس البضائع بحمولة ٨٠٠ كجم. يتميز بحمولة كبيرة وموثوقية تشغيل عالية.

آلة تكديس البضائع عالية التحميل ذات الأغراض الخاصة،

عالية السرعة ومستقرة،

تكوين المعدات البسيطة

تستخدم في حالات التعبئة الخاصة

QJRB800-1

الصين

30 يومًا

تحويل بنكي

نينغبو/شنغهاي الصين

| نموذج | QJRB800-1 | |

| رقم المحور | 4 | |

| الحمولة | 800 كجم | |

| تكرار التموضع | ±0.5 مم | |

| ماكس أرمسبان | 3159 ملم | |

ما هو روبوت التكديس؟

في عمليات التصنيع والخدمات اللوجستية الحديثة، أصبحت الأتمتة عاملاً أساسياً في تحسين الإنتاجية وخفض تكاليف العمالة. ومن بين الحلول الآلية المتنوعة، يُعدّ... روبوت التكديستُستخدم هذه الروبوتات على نطاق واسع في صناعات متنوعة، من الأغذية والمشروبات إلى الأدوية والصناعات الثقيلة. روبوت التكديس على المنصات هو نوع من الأنظمة الروبوتية المصممة خصيصًا لتكديس المنتجات أو الطرود وتنظيمها على المنصات للتخزين أو الشحن.

التعريف والوظيفة

روبوت التكديس هو ذراع روبوتية صناعية مزودة بأدوات متخصصة في نهاية الذراع (EOAT)، مصممة لالتقاط مواد مثل الصناديق والأكياس والحاويات والكرتون ووضعها بنمط مبرمج مسبقًا على منصة نقالة. تعمل هذه الروبوتات بسرعة ودقة عاليتين، مما يجعلها مثالية للمهام المتكررة في بيئات الإنتاج عالية الحجم. قد تتبع عملية التكديس أنماطًا معقدة لتحسين المساحة وضمان الاستقرار أثناء النقل.

المكونات الرئيسية

-

الذراع الروبوتيةهذا هو العنصر الأساسي في نظام التكديس. يتميز عادةً بمحاور متعددة (عادةً من 4 إلى 6)، مما يسمح له بالتحرك في اتجاهات مختلفة والتعامل مع البضائع بدقة.

-

أدوات نهاية الذراع (EOAT)يتفاعل هذا الجزء مباشرةً مع المنتج. وحسب الاستخدام، قد يكون ملقطًا، أو شفطًا بالتفريغ، أو أداة مغناطيسية، أو ملحقًا مصممًا خصيصًا.

-

نظام التحكم:عقل العملية. يسمح للمشغلين ببرمجة حركات الروبوت، وأنماط التكديس، والسرعة، ومدة الدورة.

-

ميزات السلامة:تضمن أجهزة الاستشعار والحراسة وأزرار الإيقاف في حالات الطوارئ التشغيل الآمن بما يتوافق مع لوائح السلامة في مكان العمل.

-

أنظمة الرؤية أو الاستشعار (اختياري):قد تتضمن روبوتات التكديس المتقدمة كاميرات أو أجهزة استشعار للكشف عن الاختلافات في المنتج أو عدم محاذاته والتكيف معها.

أنواع روبوتات التكديس

-

روبوتات ذات أذرع مفصلية:هذه هي الأنواع الأكثر شيوعًا، وتوفر المرونة والقدرة على التعامل مع المهام المعقدة.

-

روبوتات جسرية:تتحرك هذه المنصات على طول مسار ثابت وهي مناسبة لعمليات التعبئة على المنصات الثقيلة أو واسعة النطاق.

-

الروبوتات التعاونية (Cobots):مصمم للعمل جنبًا إلى جنب مع العمال البشريين بأمان دون سياج، ومناسب لخطوط الإنتاج المرنة أو ذات النطاق الأصغر.

التطبيقات عبر الصناعات

تُستخدم في مجموعة واسعة من الصناعات:

-

المأكولات والمشروبات:التعامل مع البضائع المعبأة والمشروبات المعبأة والأطعمة المعلبة.

-

المستحضرات الصيدلانية:تكديس صناديق الأدوية أو الإمدادات الطبية.

-

الصناعة الكيميائية:إدارة حاويات المواد الثقيلة أو الخطرة.

-

الخدمات اللوجستية والتخزين:تنظيم الطرود للشحن والتسليم.

-

زراعة:تعبئة أكياس البذور والحبوب والأسمدة على المنصات.

مزايا استخدام روبوتات التكديس

-

الكفاءة والسرعة:يمكن للروبوتات أن تعمل بشكل مستمر دون انقطاع، مما يزيد من الإنتاجية.

-

الدقة والاتساق:يضمن تقليل الخطأ البشري تكديسًا مستقرًا وموحدًا.

-

تحسين السلامة في مكان العمل:تعمل الروبوتات على تقليل خطر الإصابة نتيجة الرفع المتكرر والأحمال الثقيلة.

-

توفير العمالة:يمكن لروبوت واحد أن يحل محل العديد من العمال اليدويين، مما يقلل من تكاليف التشغيل.

-

قابلية التوسع:يمكن برمجتها بسهولة لمنتجات مختلفة، مما يجعلها مناسبة لمقاييس الإنتاج المختلفة.

اعتبارات عند اختيار روبوت التكديس

-

سعة الحمولة:اختر روبوتًا قادرًا على التعامل مع وزن المنتج الأثقل لديك.

-

الوصول والبصمة:تأكد من أن الروبوت يمكنه الوصول إلى جميع مواضع المنصات المطلوبة ضمن غلاف العمل الخاص به.

-

متطلبات السرعة:قم بمطابقة وقت دورة الروبوت مع متطلبات الإنتاج الخاصة بك.

-

تكوين التكديس:فكر فيما إذا كنت بحاجة إلى أنماط منصات فردية أو متعددة.

-

القدرة على التكامل:يجب أن يتكامل الروبوت بسهولة مع أنظمة الأتمتة والنقل الموجودة لديك.

يُعزز استخدام الذكاء الاصطناعي والتعلم الآلي قدرات روبوتات التكديس على المنصات. تتميز الأنظمة المتقدمة الآن بالتعرف الفوري على المنتجات، والتكديس التكيفي بناءً على حجم المنصات، وقدرات الصيانة التنبؤية. تُسهم هذه الابتكارات في دفع حدود الكفاءة والمرونة في بيئات الإنتاج الحديثة.

توفر شركة SHENCHI ROBOT CO.,LTD روبوتات صناعية مختلفة مع حلول الأتمتة. نحن ندعم الروبوتات الصناعية بما في ذلك اللحام والطلاء والمناولة والتكديس والانحناء والتلميع، مرحبا بكم في الاتصال بنا.

روبوت شينشي، أكثر ذكاءً وبساطة

© جميع الحقوق محفوظة لشركة شينشي.