- Wenling Zhejiang China

- [email protected]

- +86 18958695512

- Heim

- PRODUKTE

- FLIESSBAND

- Automatischer Hebedrehtisch, beste Idee, Design-Fließband

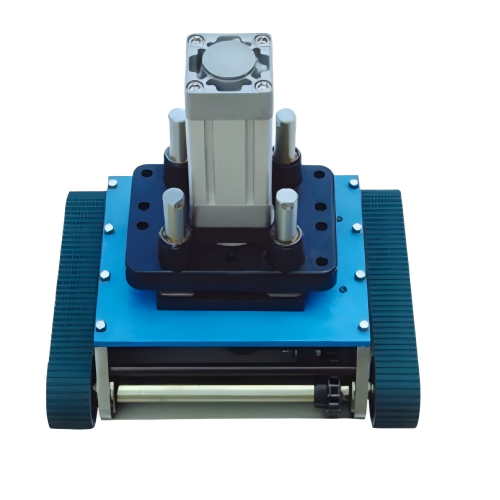

Automatischer Hebedrehtisch, beste Idee, Design-Fließband

Wir präsentieren stolz unsere Hochleistungs-Drehtisch mit automatischem Hub - ein innovativ, kostengünstig Lösung, die entwickelt wurde, um Optimierung des Materialflusses, der Positioniergenauigkeit und der Produktionseffizienz in Produktionsstätten weltweit.

Anwendungen

• Automobilmontage – Motor-/Getriebepositionierung

• Verpackungslinien – Produktorientierung & -transfer

• Bearbeitungszentren – Werkstückbe-/entladung

• Prüfstationen – 360°-Zugang zur Qualitätskontrolle

Anpassungsoptionen:

Sondertragfähigkeiten/-größen

Reinraum-/Explosionsgeschützte Varianten

Integrierte Bildverarbeitungs-/Sensorsysteme

SC-AL-63

CHINA

30 TAGE

T/T

NINGBO/SHANGHAI CHINA

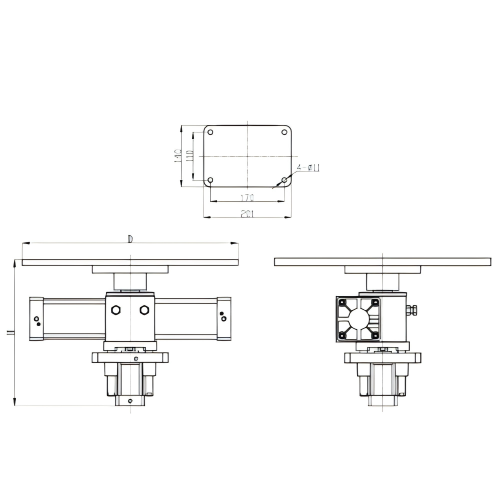

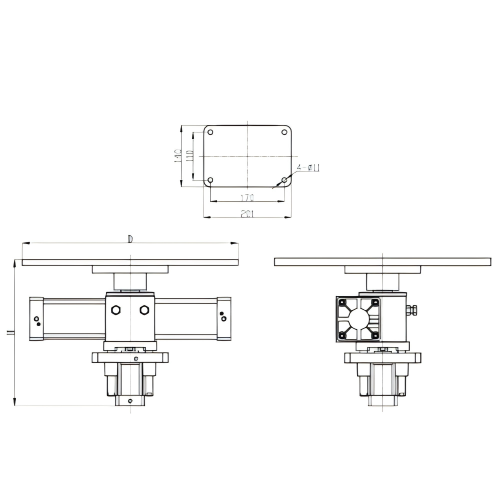

Hub: 40 mm, Zylinderdurchmesser 60 mm

Trachealschnittstelle 1/8

Automatischer Hubdrehtisch – Das ultimative intelligente Positionierungssystem für moderne Montagelinien

Ein Automatischer Hebedrehtisch ist ein elektromechanisches Positionierungssystem das kombiniert vertikale Hubbewegung mit 360°-Drehbewegung zur Optimierung des Materialhandlings in der industriellen Automatisierung. Diese Systeme werden häufig eingesetzt in Montagelinien, Verpackungs-, Bearbeitungs- und Inspektionsstationen Zu Verbesserung der Ergonomie, Präzision und Produktionseffizienz.

Wir präsentieren stolz unsere Hochleistungs-Drehtisch mit automatischem Hub - ein innovative, platzsparende Lösung das kombiniert vertikales Heben und 360°-Drehung zur Optimierung des Materialhandlings in der modernen Fertigung. Entwickelt für präzise Positionierung, ergonomische Arbeitsplätze und nahtlose Integration, unsere Plattenspieler werden von globale Hersteller in der Automobil-, Elektronik-, Verpackungs- und Schwerindustrie.

Mit über 15 Jahre Ingenieurserfahrung Und [X.000] Einheiten weltweit installiert, wir liefern:

30% schnellere Zykluszeiten vs. manuelle Positionierung

±0,1 mm vertikale / ±0,1° Rotationsgenauigkeit

Tragfähigkeiten von 50kg bis 2000kg

30% kostengünstiger als europäische Alternativen

Warum sollten Sie sich für unseren automatischen Hebedrehtisch entscheiden?

1. Präzise Zweiachsenbewegung

Sanftes vertikales Anheben (50-1000 mm Hub)

360° kontinuierliche oder indizierte Drehung

Servogesteuerte Steuerung für programmierbare Positionen

Antivibrationsdesign für stabiles Lasthandling

2. Hochleistungs-Industriekonstruktion

Verstärkte Stahlplattform mit optionaler Edelstahlplatte

Abgedichteter Kugelumlaufspindel-/Zahnstangenantrieb (IP54/IP65)

Überlastschutz mit Not-Aus

Über 50.000 Stunden Lebensdauer bei normalem Gebrauch

3. Intelligente Automatisierungsfunktionen

PLC/HMI-Steuerungsintegration

IoT-fähig für Industrie 4.0-Überwachung

Automatische Höhenverstellung für Multiprozess-Workstations

Barcode-/RFID-Tracking-Kompatibilität

4. Kostensparende Vorteile

40% weniger Stellfläche als herkömmliche Transfersysteme

20% Energieeinsparungen mit effizienten Servomotoren

Geringer Wartungsaufwand (selbstschmierende Komponenten)

Plug-and-Play-Installation

Wichtige Anwendungen

1. Automobilherstellung

Positionierung der Motor-/Getriebebaugruppe

Drehung der Schweißvorrichtung

Lackierstraßenförderung

2. Elektronikproduktion

Drehtische für die Leiterplatteninspektion

Präzisionskomponentenmontage

Integration einer Lasermarkierstation

3. Verpackung & Logistik

Karton-/Palettenausrichtung

Rotation der Etikettierstation

Sortiersystemintegration

4. Schwerindustrie

Handhabung von Werkstücken in der Metallverarbeitung

Be-/Entladen von CNC-Maschinen

Schmiedepressenbeschickung

Wettbewerbsvorteile

Höheres Verhältnis von Last zu Größe als die Konkurrenz

Schnellere Positionierungsgeschwindigkeit mit optimierter Beschleunigung

Leiserer Betrieb (<65 dB)

CE/ISO-zertifizierte Sicherheitsstandards

Anpassungsoptionen

Wir bieten:

Spezielle Plattformgrößen/-durchmesser

Explosionsgeschützte/hygienische Ausführungen

Integrierte Fördersegmente

Benutzerdefinierte Steuerungsschnittstellen

Globale Erfolgsgeschichten

Fallstudie 1: Ein deutscher Automobilzulieferer reduzierte die Teiletransferzeit bei der Batteriemontage durch den Einsatz unserer Drehtische um 35%.

Fallstudie 2: Japanischer Elektronikhersteller erreichte eine Positionierungsgenauigkeit von 99,98% für die Montage von Mikrokomponenten.

Warum Hersteller uns vertrauen?

ISO 9001 & CE-zertifizierte Produktion

Über 15 Jahre Erfahrung im Bereich Bewegungssteuerung

Mehrsprachiger technischer Support rund um die Uhr

3 Jahre Garantie mit Ersatzteilgarantie

Rüsten Sie Ihre Montagelinie noch heute auf!

Unser Automatische Hebedrehtische liefern:

Schnellere Produktionszyklen

Ergonomische Arbeitsplatzgestaltung

Zukunftssichere Automatisierung

SHENCHI ROBOT CO., LTD bietet verschiedene Industrieroboter mit Automatisierungslösungen. Wir unterstützen Industrieroboter einschließlich Schweißen, Lackieren, Handhaben, Palettieren, Biegen und Polieren. Kontaktieren Sie uns gerne.

Shenchi Roboter, intelligenter, einfacher

KONTAKTIEREN SIE UNS

© Shenchi Company. Alle Rechte vorbehalten.