- Wenling Zhejiang Κίνα

- [email protected]

- +86 18958695512

- Σπίτι

- ΠΡΟΪΟΝΤΑ

- ΒΙΟΜΗΧΑΝΙΚΟ ΡΟΜΠΟΤ

- ΑΛΛΕΣ ΕΦΑΡΜΟΓΕΣ ΡΟΜΠΟΤ

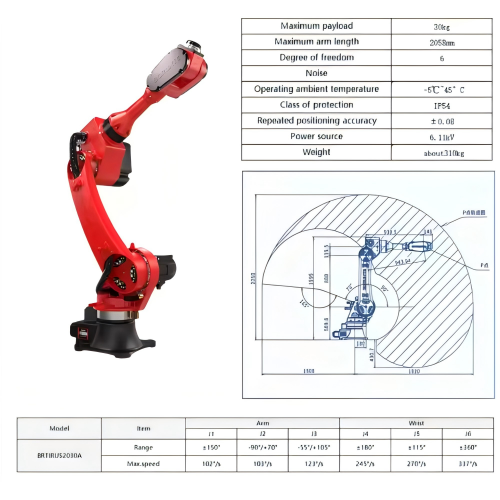

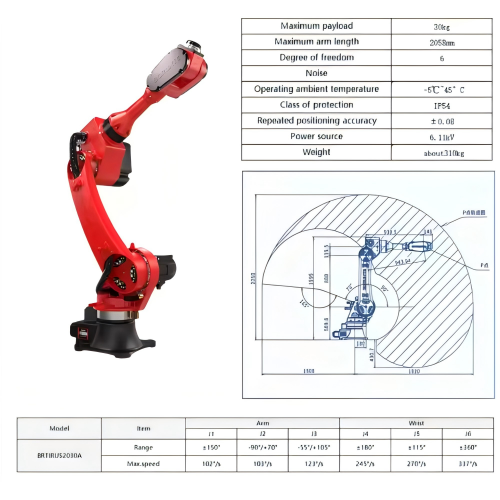

- Ρομποτικός βραχίονας υψηλής ακρίβειας 30kg με τις καλύτερες πωλήσεις σε ζεστό στυλ με CE

Ρομποτικός βραχίονας υψηλής ακρίβειας 30kg Hot Sell με πιστοποίηση CE

Παρουσιάζουμε το Βραχίονας ρομπότ υψηλής ακρίβειας, σχεδιασμένο για να διαπρέπει μονότονες, υψηλής συχνότητας εργασίες και επικίνδυνα περιβάλλονταΑυτό Βραχίονας ρομπότ 6 αξόνων με πιστοποίηση CE παραδίδει απαράμιλλη ακρίβεια (επαναληψιμότητα ±0,02 mm) και ευελιξία πολλαπλών βαθμών ελευθερίας, καθιστώντας το ιδανικό για

Στίλβωση ακριβείας αεροδιαστημικών/ιατρικών εξαρτημάτων

Μικροσυναρμολόγηση ηλεκτρονικών και ευαίσθητων εξαρτημάτων

Συνεπής βαφή με ψεκασμό με τέλειο φινίρισμα

Επιφανειακή επεξεργασία σε δύσκολες συνθήκες

Με κίνηση πολλαπλών βαθμών ελευθερίας και βελτιωμένη ευελιξία, η λύση High Precision Robot υπερέχει σε διάφορες εφαρμογές, όπως στίλβωση ακριβείας, εργασίες συναρμολόγησης, βαφή με ψεκασμό και διαδικασίες επεξεργασίας επιφανειών. Ο στιβαρός σχεδιασμός του εξασφαλίζει αξιόπιστη απόδοση σε απαιτητικά βιομηχανικά περιβάλλοντα, διατηρώντας παράλληλα εξαιρετική σταθερότητα θέσης.

SC-BR2030

ΚΙΝΑ

30 ΗΜΕΡΕΣ

Φ/Φ

NINGBO/ΣΑΓΚΑΗ ΚΙΝΑ

| Άξονες | 6 άξονες | ||||||||||||

| Δυνατότητα φόρτωσης | 7 κιλά | ||||||||||||

| Κωδικός IP | IP65 Ανθεκτικό στη σκόνη και το νερό | ||||||||||||

| Επαναλαμβανόμενη τοποθέτηση ακρίβεια | ±0,03 χιλ. | ||||||||||||

| Μέγιστο άνοιγμα βραχίονα | 700 χιλιοστά | ||||||||||||

| Βάρος | 55 κιλά | ||||||||||||

Ρομπότ Υψηλής Ακρίβειας: Η Απόλυτη Λύση για Αριστεία Βιομηχανικού Αυτοματισμού

Στο σημερινό ταχέως εξελισσόμενο τοπίο της μεταποίησης, η ακρίβεια και η αξιοπιστία δεν είναι πλέον προαιρετικές – είναι απαραίτητες για τη διατήρηση του ανταγωνιστικού πλεονεκτήματος. Βραχίονας ρομπότ υψηλής ακρίβειας αντιπροσωπεύει την κορωνίδα της τεχνολογίας βιομηχανικού αυτοματισμού, ειδικά σχεδιασμένη για μονότονες, επαναλαμβανόμενες εργασίες υψηλής συχνότητας σε επικίνδυνα ή απαιτητικά περιβάλλονταΜε το κίνημα πολλαπλών βαθμών ελευθερίας και βελτιωμένη ευελιξία, αυτό Ρομποτικός βραχίονας 6 αξόνων προσφέρει απαράμιλλη απόδοση σε γυάλισμα ακριβείας, εργασίες συναρμολόγησης, βαφή με ψεκασμό και διαδικασίες επεξεργασίας επιφανειών.

Πιστοποιημένο με Πιστοποίηση CE για τη συμμόρφωση με την ευρωπαϊκή αγορά, αυτό Νέος βραχίονας ρομπότ συνδυασμοί Γερμανική μηχανική ακρίβεια με Αξιοπιστία κατασκευής στην Ιαπωνία, προσφέροντας στους κατασκευαστές παγκοσμίως ένα λύση αυτοματισμού με δυνατότητα προσαρμογής στο μέλλον που ενισχύει σημαντικά την παραγωγικότητα μειώνοντας παράλληλα το λειτουργικό κόστος.

Ρομποτικός βραχίονας υψηλής ακρίβειας, απαράμιλλες τεχνικές προδιαγραφές

Βασικές μετρήσεις απόδοσης

-

Επαναληψιμότητα: ±0,02 mm (κορυφαία ακρίβεια στον κλάδο)

-

Μέγιστη ταχύτητα: 3,0 m/s (εξαιρετικά υψηλή απόδοση)

-

Χωρητικότητα ωφέλιμου φορτίου: 5-15kg (διαμορφώσιμο)

-

Βαθμοί Ελευθερίας: Πλήρης άρθρωση 6 αξόνων

-

Βαθμολογία προστασίας: IP67 (ανθεκτικό στη σκόνη και στο νερό)

Προηγμένο σύστημα ελέγχου κίνησης

-

Κωδικοποιητές απόλυτης τιμής υψηλής ανάλυσης (17-bit+)

-

Προηγμένη καταστολή κραδασμών τεχνολογία

-

Δυναμικός έλεγχος ροπής για λεπτές επεμβάσεις

-

Διόρθωση διαδρομής σε πραγματικό χρόνο κατά τη λειτουργία

Έξυπνη ενσωμάτωση εργοστασίου

-

OPC UA και PROFINET αρμονία

-

Έτοιμο για IoT με συνδεσιμότητα cloud

-

Προβλεπτική συντήρηση δυνατότητες

-

Ψηφιακό δίδυμο υποστήριξη προσομοίωσης

Βραχίονας ρομπότ υψηλής ακρίβειας για εφαρμογές που αφορούν συγκεκριμένους κλάδους

1. Γυάλισμα και φινίρισμα ακριβείας

-

Φινίρισμα εξαρτημάτων αυτοκινήτων

-

Στίλβωση λεπίδων αεροδιαστημικής τουρμπίνας

-

Επεξεργασία επιφάνειας ιατρικών συσκευών

-

Φινίρισμα περιβλήματος ηλεκτρονικών ειδών ευρείας κατανάλωσης

Μελέτη περίπτωσης: Μειωμένος χρόνος κύκλου στίλβωσης κατά 40%, ενώ παράλληλα βελτιώθηκε η συνοχή του φινιρίσματος της επιφάνειας κατά 65% για έναν Γερμανό προμηθευτή αυτοκινήτων.

2. Λειτουργίες συναρμολόγησης υψηλής ταχύτητας

-

Τοποθέτηση ηλεκτρονικών εξαρτημάτων

-

Μηχανική συναρμολόγηση ακριβείας

-

Χειρισμός και τοποθέτηση μικροεξαρτημάτων

-

Αυτόματα συστήματα βιδώματος

3. Προηγμένη επεξεργασία επιφάνειας

-

Ομοιόμορφες εφαρμογές βαφής με ψεκασμό

-

Εναπόθεση ακριβούς επικάλυψης

-

Επεξεργασία επιφάνειας με λέιζερ

-

Διαδικασίες επικάλυψης με πλάσμα

4. Επικίνδυνες Περιβαλλοντικές Λειτουργίες

-

Χειρισμός σε εκρηκτική ατμόσφαιρα (επιλογές ATEX)

-

Εφαρμογές χυτηρίου υψηλής θερμοκρασίας

-

Εκδόσεις συμβατές με καθαρούς χώρους

-

Διαβρωτικά χημικά περιβάλλοντα

Ανταγωνιστικά πλεονεκτήματα έναντι των συμβατικών ρομπότ

1. Απαράμιλλη Απόδοση Ακριβείας

-

30% υψηλότερη ακρίβεια από συγκρίσιμα ρομπότ

-

Προηγμένος έλεγχος κραδασμών για ακρίβεια σε μικροεπίπεδο

-

Θερμική αντιστάθμιση για σταθερή απόδοση

2. Βελτιωμένα χαρακτηριστικά αντοχής

-

Δρομολόγηση θωρακισμένων καλωδίων για εκτεταμένη διάρκεια ζωής

-

Ενισχυμένες αρμονικές κινήσεις (Μέσο MTBF 50.000 ωρών)

-

Επιστρώσεις ανθεκτικές στη διάβρωση για σκληρά περιβάλλοντα

3. Έτοιμο για έξυπνη κατασκευή

-

Ενσωματωμένη ανίχνευση δύναμης/ροπής

-

Προσαρμοστικός έλεγχος με τεχνητή νοημοσύνη

-

Απομακρυσμένη διάγνωση και παρακολούθηση

-

Συστήματα ανάκτησης ενέργειας (εξοικονόμηση ενέργειας έως 15%)

4. Οφέλη Βελτιστοποίησης Κόστους

-

50% μείωση των αποβλήτων αναλώσιμων

-

60% μείωση των ποσοστών επανεπεξεργασίας

-

Απόδοση επένδυσης (ROI) εντός 8-14 μηνών για τις περισσότερες εφαρμογές

Σύγκριση με ανταγωνιστικά μοντέλα

Διαθέσιμες επιλογές προσαρμογής βραχίονα ρομπότ υψηλής ακρίβειας

1. Εξειδικευμένοι τελικοί ενεργοποιητές

-

Μικρο-λαβίδες για ευαίσθητα εξαρτήματα

-

Μαγνητικός χειρισμός για σιδηρούχα υλικά

-

Συστοιχίες κυπέλλων κενού για μεγάλα πάνελ

-

Συμβατά εργαλεία για προσαρμοστική συναρμολόγηση

2. Παραλλαγές που αφορούν το περιβάλλον

-

Κλάση καθαρού χώρου (ISO 3-5)

-

Αντιεκρηκτική προστασία (ATEX Ζώνη 1)

-

Υψηλή θερμοκρασία (έως 150°C)

-

Έτοιμο για πλύσιμο (IP69K)

3. Προηγμένη Ενσωμάτωση Αισθητήρων

-

Συστήματα καθοδήγησης τρισδιάστατης όρασης

-

Σάρωση με λέιζερ για ποιοτικό έλεγχο

-

Αισθητήρας δύναμης-ροπής για προσαρμοστικό χειρισμό

-

Κάμερες επιθεώρησης επιφάνειας

Υπηρεσίες Υλοποίησης & Υποστήριξης

1. Επαγγελματική εγκατάσταση

-

Αξιολόγηση και σχεδιασμός χώρου

-

Σχεδιασμός προσαρμοσμένου κελιού εργασίας

-

Ενσωμάτωση συστήματος ασφαλείας

-

Προσομοίωση γραμμής παραγωγής

2. Ολοκληρωμένη Εκπαίδευση

-

Προγράμματα πιστοποίησης χειριστών

-

Εκπαίδευση τεχνικού συντήρησης

-

Masterclasses προγραμματισμού

-

Εργαστήρια αντιμετώπισης προβλημάτων

3. Συνεχής Υποστήριξη

-

24/7 τεχνική βοήθεια

-

Συμβόλαια προληπτικής συντήρησης

-

Διαχείριση αποθέματος ανταλλακτικών

-

Υπηρεσίες αναβάθμισης λογισμικού

Γιατί οι παγκόσμιοι κατασκευαστές επιλέγουν βραχίονα ρομπότ υψηλής ακρίβειας

Η Λύση μας

1. Αποδεδειγμένη αξιοπιστία

-

MTBF 60.000 ωρών σε επιχειρήσεις πεδίου

-

Επικυρωμένο σε 500+ εγκαταστάσεις παγκοσμίως

-

Επιλογή εξαρτημάτων στρατιωτικής ποιότητας

2. Τεχνολογία που ανταποκρίνεται στο μέλλον

-

Δυνατότητα αναβάθμισης υλικολογισμικού σε νέα πρότυπα

-

Αρθρωτός σχεδιασμός για εύκολη βελτίωση

-

Διασφάλιση συμβατότητας με παλαιότερες εκδόσεις

3. Βιώσιμη Παραγωγή

-

Ενεργειακά αποδοτικά σερβοσυστήματα

-

Μειωμένα αναλώσιμα απόβλητα

-

Ανακυκλώσιμα δομικά υλικά

-

Λειτουργία χαμηλού αποτυπώματος άνθρακα

Συμπέρασμα: Μεταμορφώστε την παραγωγή σας σήμερα

Μας Ρομπότ υψηλής ακρίβειας αντιπροσωπεύει την επόμενη γενιά βιομηχανικού αυτοματισμού, προσφέροντας στους κατασκευαστές πρωτοφανής ακρίβεια, αξιοπιστία και ευελιξία στις δραστηριότητές τους. Είτε θέλετε να βελτίωση της ποιότητας στο γυάλισμα ακριβείας, αύξηση της παραγωγικότητας στις γραμμές συναρμολόγησης, ή βελτίωση της συνοχής στις επιφανειακές επεξεργασίες, αυτό Βραχίονας ρομπότ 6 αξόνων με πιστοποίηση CE προσφέρει μετρήσιμες βελτιώσεις στην απόδοση από την πρώτη κιόλας ημέρα.

Με προσαρμόσιμες διαμορφώσεις για την κάλυψη συγκεκριμένων απαιτήσεων εφαρμογής και ολοκληρωμένες υπηρεσίες υποστήριξης για να διασφαλιστεί η απρόσκοπτη ενσωμάτωση, η τεχνολογία ρομπότ υψηλής ακρίβειας που διαθέτουμε παρέχει ένα γρήγορη απόδοση επένδυσης (ROI) ενώ προετοιμασία για το μέλλον την υποδομή αυτοματισμού σας.

Κάντε το επόμενο βήμα στην αριστεία στην κατασκευή – επικοινωνήστε με τους ειδικούς μας στον αυτοματισμό σήμερα για μια εξατομικευμένη συμβουλευτική και επίδειξη.

Η SHENCHI ROBOT CO.,LTD παρέχει διάφορα βιομηχανικά ρομπότ με λύσεις αυτοματισμού. Υποστηρίζουμε βιομηχανικά ρομπότ, όπως συγκόλληση, βαφή, χειρισμό, παλετοποίηση, κάμψη και στίλβωση. Καλώς ήρθατε να επικοινωνήσετε μαζί μας.

Ρομπότ Shenchi, πιο έξυπνο, πιο απλό

ΕΠΙΚΟΙΝΩΝΗΣΤΕ ΜΑΖΙ ΜΑΣ

© Εταιρεία Shenchi Με επιφύλαξη παντός δικαιώματος.