- Wenling Zhejiang China

- [email protected]

- +86 18958695512

- Hogar

- PRODUCTOS

- LÍNEA DE MONTAJE

- La mejor idea para diseñar una línea de montaje con plataforma giratoria de elevación automática

La mejor idea para diseñar una línea de montaje con plataforma giratoria de elevación automática

Presentamos con orgullo nuestro Plataforma giratoria de elevación automática de alto rendimiento - un innovador, rentable solución diseñada para Optimizar el flujo de material, la precisión de posicionamiento y la eficiencia de producción en instalaciones de fabricación en todo el mundo.

Aplicaciones

• Ensamblaje de automóviles – Posicionamiento del motor/transmisión

• Líneas de embalaje – Orientación y transferencia de productos

• Centros de mecanizado – Carga/descarga de piezas de trabajo

• Estaciones de inspección – Acceso de 360° para control de calidad

Opciones de personalización:

Capacidades/tamaños de carga especiales

Variantes para salas blancas/a prueba de explosiones

Sistemas integrados de visión y sensores

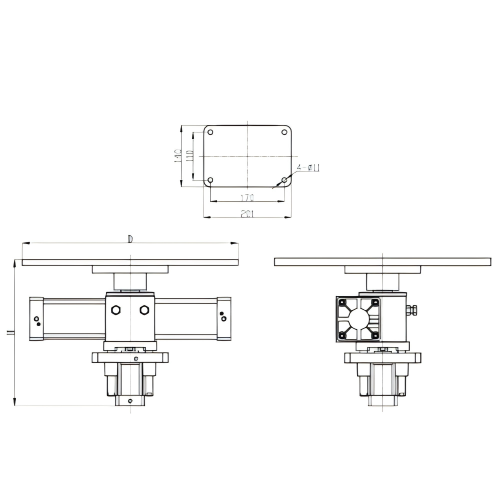

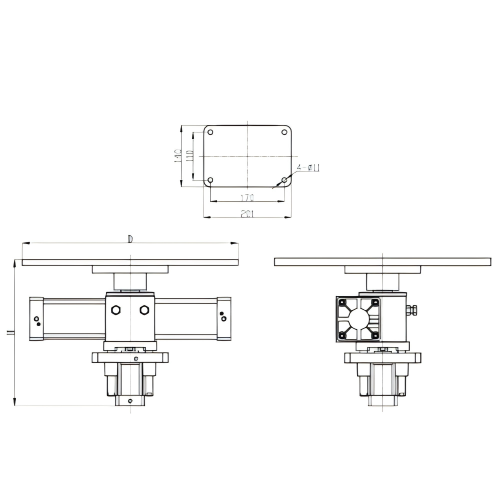

SC-AL-63

PORCELANA

30 DÍAS

Transferencia bancaria

NINGBO/SHANGHÁI CHINA

Carrera de elevación: 40 mm, diámetro del cilindro 60 mm

interfaz traqueal 1/8

Plataforma giratoria de elevación automática: el sistema de posicionamiento inteligente definitivo para líneas de montaje modernas

Un Plataforma giratoria de elevación automática es un sistema de posicionamiento electromecánico que combina movimiento de elevación vertical con movimiento de rotación de 360° Para optimizar la manipulación de materiales en la automatización industrial. Estos sistemas se utilizan ampliamente en líneas de montaje, embalaje, mecanizado y estaciones de inspección a mejorar la ergonomía, la precisión y la eficiencia de la producción.

Presentamos con orgullo nuestro Plataforma giratoria de elevación automática de alto rendimiento - un solución innovadora que ahorra espacio que combina elevación vertical y rotación de 360° Para optimizar el manejo de materiales en la fabricación moderna. Diseñado para Posicionamiento de precisión, estaciones de trabajo ergonómicas e integración perfectaNuestros tocadiscos cuentan con la confianza de Fabricantes globales de automoción, electrónica, embalaje e industrias pesadas.

Con Más de 15 años de experiencia en ingeniería y [X,000] unidades instaladas en todo el mundo, entregamos:

30% tiempos de ciclo más rápidos vs posicionamiento manual

Precisión vertical de ±0,1 mm / rotación de ±0,1°

Capacidades de carga desde 50 kg hasta 2000 kg

30% más rentable que las alternativas europeas

¿Por qué elegir nuestra plataforma giratoria de elevación automática?

1. Movimiento de precisión de doble eje

Elevación vertical suave (carrera de 50-1000 mm)

Rotación continua o indexada de 360°

Control servoaccionado para posiciones programables

Diseño antivibración para un manejo estable de la carga

2. Construcción industrial de servicio pesado

Plataforma de acero reforzado con tapa de acero inoxidable opcional

Transmisión por tornillo de bolas sellado/por cremallera y piñón (IP54/IP65)

Protección contra sobrecargas con parada de emergencia

Vida útil de más de 50.000 horas bajo uso normal

3. Funciones de automatización inteligente

Integración de control PLC/HMI

Listo para IoT para la monitorización de la Industria 4.0

Ajuste automático de altura para estaciones de trabajo multiproceso

Compatibilidad con seguimiento de códigos de barras/RFID

4. Ventajas de ahorro de costes

40% menos espacio en el piso que los sistemas de transferencia tradicionales

Ahorro de energía 20% con servomotores eficientes

Bajo mantenimiento (componentes autolubricantes)

Instalación plug-and-play

Aplicaciones clave

1. Fabricación de automóviles

Posicionamiento del conjunto motor/transmisión

Rotación del dispositivo de soldadura

Transporte de línea de pintura

2. Producción electrónica

Platos giratorios de inspección de PCB

Ensamblaje de componentes de precisión

Integración de la estación de marcado láser

3. Embalaje y logística

Orientación de cajas/palets

Rotación de la estación de etiquetado

Integración del sistema de clasificación

4. Industria pesada

Manipulación de piezas de fabricación de metal

Carga/descarga de máquinas CNC

Alimentación de prensa de forja

Ventajas competitivas

Mayor relación carga-tamaño que los competidores

Velocidad de posicionamiento más rápida con aceleración optimizada

Funcionamiento más silencioso (<65 dB)

Normas de seguridad certificadas CE/ISO

Opciones de personalización

Ofrecemos:

Tamaños/diámetros de plataforma especiales

Versiones a prueba de explosiones/higiénicas

Segmentos transportadores integrados

Interfaces de control personalizadas

Historias de éxito globales

Estudio de caso 1: Un proveedor de automóviles alemán redujo el tiempo de transferencia de piezas en 35% utilizando nuestras plataformas giratorias en el ensamblaje de baterías.

Estudio de caso 2: El fabricante japonés de productos electrónicos logró una precisión de posicionamiento del 99,98% para el ensamblaje de microcomponentes.

¿Por qué los fabricantes confían en nosotros?

Producción con certificación ISO 9001 y CE

Más de 15 años de experiencia en control de movimiento

Soporte técnico multilingüe 24/7

Garantía de 3 años con garantía de repuestos

¡Actualice su línea de montaje hoy!

Nuestro Plataformas giratorias de elevación automática entregar:

Ciclos de producción más rápidos

Diseño ergonómico de la estación de trabajo

Automatización a prueba de futuro

SHENCHI ROBOT CO., LTD ofrece diferentes robots industriales con soluciones de automatización. Admitimos robots industriales que incluyen soldadura, pintura, manipulación, paletizado, doblado y pulido, bienvenido a contactarnos.

Robot Shenchi, más inteligente y más simple.

© Shenchi Company Todos los derechos reservados.