- Wenling Zhejiang China

- [email protected]

- +86 18958695512

- Hogar

- PRODUCTOS

- LÍNEA DE MONTAJE

- Línea de producción de mesa giratoria para línea de ensamblaje de lavadoras

Línea de producción de mesa giratoria para línea de ensamblaje de lavadoras

Nos especializamos en personalizado Líneas de montaje de lavadoras con alta eficiencia Línea de producción de transportadores de mesa giratoria tecnología. Nuestros sistemas automatizados reemplazan el trabajo manual, entregando Precisión (±0,5 mm), velocidad (más de 100 unidades/hora) y seguridad para fabricantes globales.

Beneficios clave:

Volteo y posicionamiento inteligentes – Rotación de 360° servocontrolada

Diseño modular – Se adapta a todo tipo de lavadoras (carga superior/frontal)

Ahorro de costes 30% frente a las alternativas europeas

Más de 500 líneas instaladas mundial

SC-AL-012

PORCELANA

30 DÍAS

Transferencia bancaria

NINGBO/SHANGHÁI CHINA

Línea de montaje avanzada de lavadoras con transportadores de mesa giratoria: su solución de fabricación inteligente

Nos especializamos en Líneas de montaje de lavadoras personalizadas que revolucionan la fabricación de electrodomésticos. Nuestra innovadora Línea de producción de transportadores de mesa giratoria reemplaza el trabajo manual con automatización inteligente de alta precisión, entregando Eficiencia, precisión y seguridad inigualables Para fabricantes globales. Con más de [X] años de experiencia en la industria y [X] instalaciones exitosas en todo el mundo, ofrecemos Soluciones de montaje rentables y de alta calidad que reducen significativamente los ciclos de producción manteniendo rigurosos estándares de calidad.

¿Por qué elegir nuestra línea de montaje de lavadoras?

1. Sistema transportador de mesa giratoria inteligente

Rotación de precisión de 360° – Garantiza una alineación perfecta de los componentes para cada etapa del montaje

Posicionamiento servocontrolado – Precisión de ±0,5 mm para una producción sin errores

Diseño modular – Adaptable a varios modelos de lavadoras (carga superior/carga frontal)

Enclavamientos de seguridad – Los sensores láser y las paradas de emergencia protegen a los operadores

2. Proceso de montaje totalmente automatizado

Alimentación automática de componentes – Motores, tinas, paneles de control

Estaciones de atornillado robótico – Aplicación de par constante

Automatización de pruebas de fugas – Detección de presión computarizada

Alineación guiada por láser – Equilibrio perfecto del tambor

4. Ventajas competitivas de fabricación

30% Tiempos de ciclo más rápidos vs líneas convencionales

55% Reducción de costos laborales a través de la automatización

<0,2% Tasa de defectos – Superior al montaje manual

15% Ahorro de energía con sistemas de accionamiento eficientes

Componentes clave de nuestra línea de montaje

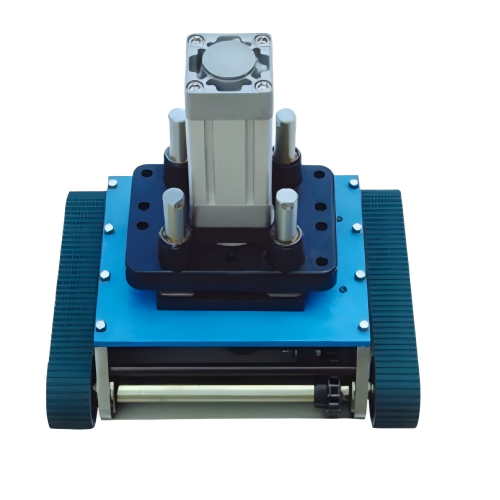

1. Transportadores de mesa giratoria inteligentes

Rotación motorizada – Giro programable de 90°/180°/270°

Diseño antivibración – Estabiliza tinas de lavadoras pesadas

Accesorios de cambio rápido – Cambio de modelo en menos de 5 minutos

2. Estaciones de subensamblaje automatizadas

Robot de inserción de tambor – Maneja cargas de 15-25 kg con precisión

Instalador del panel de control – Colocación de componentes a prueba de errores

Aplicación automática de juntas – Dispensación uniforme de sellador

3. Integración del control de calidad

Inspección por visión artificial – Detecta defectos superficiales

Prueba de peso automática – Verifica la correcta instalación de los componentes

Simulación de vibraciones – Pruebas de garantía de calidad

Beneficios líderes en la industria

1. Eficiencia de producción inigualable

Operación 24/7 – 3x de salida vs líneas manuales

Fabricación justo a tiempo – Reduce los costos de inventario

Monitoreo de producción en tiempo real – Panel de seguimiento de OEE

2. Mejora de la calidad del producto

Elimina el error humano en pasos críticos de montaje

Aplicación de par constante en todos los sujetadores

Proceso estandarizado en todos los turnos de producción

3. Mejoras en la seguridad de los trabajadores

Estaciones de trabajo ergonómicas – Reduce las lesiones laborales

Piezas móviles protegidas – Normas de seguridad conformes con la CE

Reducción de ruido – Entorno de trabajo <75dB

Historias de éxito globales

Estudio de caso 1: El fabricante europeo de electrodomésticos aumentó su producción en 40% y redujo los costes laborales en 350.000 € anuales tras implementar nuestra línea de montaje.

Estudio de caso 2: El OEM asiático logró una tasa de rendimiento de primera pasada de 99,31 TP3T y redujo el espacio de producción en 251 TP3T con nuestro diseño modular compacto.

Opciones de personalización

Capacidad de línea – De 50 a 500 unidades/día

Accesorios especiales – Para modelos compactos/de gran tamaño

Integración de marca – Esquemas de colores personalizados

Diseño a prueba de futuro – Listo para actualizaciones de IIoT

Estructura de precios competitivos

Líneas completas – Desde $150.000 (20% por debajo de los equivalentes europeos)

Modernizaciones – Modernizar las líneas existentes por 35-50% menos que las nuevas

Opciones de arrendamiento – Disponible para mercados emergentes

¿Por qué los compradores globales nos eligen?

Garantía de 5 años en componentes críticos

Instalación en 60 días con entrenamiento incluido

Socios de servicios locales en 12 países

Garantía de repuestos – 2 años de disponibilidad

Con Más de 15 años de instalaciones exitosas en todo el mundoNuestras líneas de montaje han ayudado a marcas globales aumentar la producción en 40%, reducir los costos laborales en 50% y lograr tasas de defectos por debajo de 0,5%. Ya sea que produzcas lavadoras de carga superior, de carga frontal o comerciales, nuestro línea de montaje totalmente automatizada Las soluciones se pueden personalizar para satisfacer sus requisitos de producción exactos.

SHENCHI ROBOT CO., LTD ofrece diferentes robots industriales con soluciones de automatización. Admitimos robots industriales que incluyen soldadura, pintura, manipulación, paletizado, doblado y pulido, bienvenido a contactarnos.

Robot Shenchi, más inteligente y más simple.

© Shenchi Company Todos los derechos reservados.