- Wenling Zhejiang China

- [email protected]

- +86 18958695512

- Hogar

- PRODUCTOS

- ROBOT INDUSTRIAL

- OTRAS APLICACIONES ROBOT

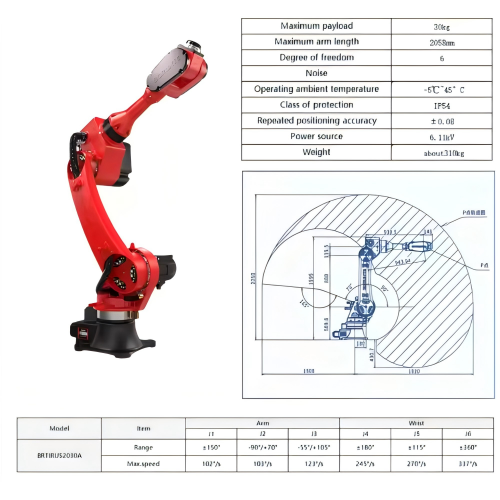

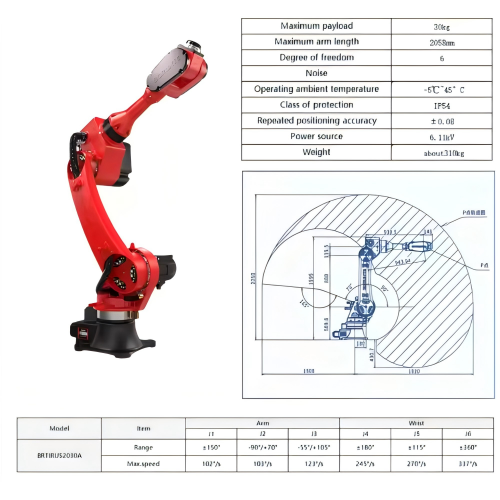

- Brazo robótico de alta precisión de 30 kg, el más vendido, estilo popular con certificación CE.

Brazo robótico de alta precisión de 30 kg, muy popular con certificación CE.

Presentando nuestro Brazo robótico de alta precisión, diseñado para sobresalir en tareas monótonas y de alta frecuencia y entornos peligrosos. Este Brazo robótico de 6 ejes con certificación CE entrega Precisión inigualable (repetibilidad de ±0,02 mm) y flexibilidad de múltiples grados de libertad, lo que lo hace ideal para

Pulido de precisión de componentes aeroespaciales/médicos

Microensamblaje de electrónica y piezas delicadas

Pintura en aerosol consistente con acabado perfecto

Tratamiento de superficies en condiciones difíciles

Con múltiples grados de libertad de movimiento y mayor flexibilidad, la solución de robot de alta precisión destaca en diversas aplicaciones, como pulido de precisión, operaciones de ensamblaje, pintura en aerosol y procesos de tratamiento de superficies. Su diseño robusto garantiza un rendimiento fiable en entornos industriales exigentes, manteniendo una excepcional consistencia posicional.

SC-BR2030

PORCELANA

30 DÍAS

Transferencia bancaria

NINGBO/SHANGHÁI CHINA

| Ejes | 6 ejes | ||||||||||||

| Capacidad de carga | 7 kilos | ||||||||||||

| Código IP | IP65 a prueba de polvo y agua | ||||||||||||

| Posicionamiento repetido exactitud | ±0,03 mm | ||||||||||||

| Máxima extensión del brazo | 700 mm | ||||||||||||

| Peso | 55 kilos | ||||||||||||

Robot de alta precisión: la solución definitiva para la excelencia en la automatización industrial

En el panorama de fabricación actual, que evoluciona rápidamente, la precisión y la confiabilidad ya no son opcionales: son esenciales para mantener una ventaja competitiva. Brazo robótico de alta precisión Representa la cúspide de la tecnología de automatización industrial, diseñada específicamente para tareas repetitivas, monótonas y de alta frecuencia en entornos peligrosos o desafiantes. Con su movimiento de múltiples grados de libertad y mayor flexibilidad, este Brazo robótico de 6 ejes Ofrece un rendimiento inigualable en pulido de precisión, operaciones de ensamblaje, pintura en aerosol y procesos de tratamiento de superficies.

Certificado con Certificación CE Para el cumplimiento del mercado europeo, este Nuevo brazo robótico combina Precisión de ingeniería alemana con Confiabilidad de la fabricación japonesa, ofreciendo a los fabricantes de todo el mundo una solución de automatización a prueba de futuro que mejora significativamente la productividad al tiempo que reduce los costos operativos.

Brazo robótico de alta precisión Especificaciones técnicas inigualables

Métricas de rendimiento básicas

-

Repetibilidad: ±0,02 mm (precisión líder en la industria)

-

Velocidad máxima: 3,0 m/s (rendimiento ultraalto)

-

Capacidad de carga útil: 5-15 kg (configurable)

-

Grados de libertad: Articulación completa de 6 ejes

-

Clasificación de protección: IP67 (a prueba de polvo y agua)

Sistema avanzado de control de movimiento

-

Codificadores absolutos de alta resolución (17 bits+)

-

Supresión avanzada de vibraciones tecnología

-

Control dinámico de par para operaciones delicadas

-

Corrección de trayectoria en tiempo real durante la operación

Integración de fábricas inteligentes

-

OPC UA y PROFINET compatibilidad

-

Listo para IoT con conectividad en la nube

-

Mantenimiento predictivo capacidades

-

Gemelo digital soporte de simulación

Brazo robótico de alta precisión para aplicaciones específicas de la industria

1. Pulido y acabado de precisión

-

Acabado de componentes automotrices

-

Pulido de álabes de turbinas aeroespaciales

-

Tratamiento de superficies de dispositivos médicos

-

Acabado de carcasas de productos electrónicos de consumo

Estudio de caso: Se redujo el tiempo del ciclo de pulido en 40% y se mejoró la consistencia del acabado de la superficie en 65% para un proveedor automotriz alemán.

2. Operaciones de ensamblaje de alta velocidad

-

Colocación de componentes electrónicos

-

Montaje mecánico de precisión

-

Manipulación y montaje de micropiezas

-

Sistemas de atornillado automatizados

3. Tratamiento avanzado de superficies

-

Aplicaciones uniformes de pintura en aerosol

-

Deposición de recubrimiento de precisión

-

Tratamiento de superficies con láser

-

Procesos de recubrimiento por plasma

4. Operaciones en entornos peligrosos

-

Manejo de atmósferas explosivas (opciones ATEX)

-

Aplicaciones de fundición de alta temperatura

-

Versiones compatibles con salas blancas

-

Entornos químicos corrosivos

Ventajas competitivas sobre los robots convencionales

1. Rendimiento de precisión inigualable

-

30% mayor precisión que robots comparables

-

Control avanzado de vibraciones para precisión a nivel micro

-

Compensación térmica para un rendimiento consistente

2. Características de durabilidad mejoradas

-

Enrutamiento de cables blindados para una vida útil más prolongada

-

Impulsores armónicos reforzados (MTBF de 50.000 h)

-

Recubrimientos resistentes a la corrosión para entornos hostiles

3. Fabricación inteligente lista

-

Detección de fuerza/torque integrada

-

Control adaptativo impulsado por IA

-

Diagnóstico y monitorización remota

-

Sistemas de recuperación de energía (hasta 15% de ahorro de energía)

4. Beneficios de la optimización de costos

-

50% reducción de residuos de consumibles

-

60% disminución en las tasas de retrabajo

-

ROI en un plazo de 8 a 14 meses para la mayoría de aplicaciones

Comparación con modelos de la competencia

Opciones de personalización de brazo robótico de alta precisión disponibles

1. Efectores finales especializados

-

Micropinzas para componentes delicados

-

Manipulación magnética para materiales ferrosos

-

Matrices de ventosas para paneles grandes

-

Herramientas compatibles para montaje adaptativo

2. Variantes específicas del entorno

-

Clase de sala limpia (ISO 3-5)

-

A prueba de explosiones (ATEX Zona 1)

-

Alta temperatura (hasta 150°C)

-

Apto para lavado (IP69K)

3. Integración avanzada de sensores

-

Sistemas de guía por visión 3D

-

Escaneo láser para control de calidad

-

Detección de fuerza-par para un manejo adaptativo

-

Cámaras de inspección de superficies

Servicios de implementación y soporte

1. Instalación profesional

-

Evaluación y planificación del sitio

-

Diseño de celda de trabajo personalizado

-

Integración de sistemas de seguridad

-

Simulación de línea de producción

2. Formación integral

-

Programas de certificación de operadores

-

Capacitación de técnicos de mantenimiento

-

Clases magistrales de programación

-

Talleres de resolución de problemas

3. Soporte continuo

-

Asistencia técnica 24/7

-

Contratos de mantenimiento preventivo

-

Gestión de inventario de repuestos

-

Servicios de actualización de software

¿Por qué los fabricantes globales eligen un brazo robótico de alta precisión?

Nuestra solución

1. Confiabilidad comprobada

-

MTBF de 60.000 horas en operaciones de campo

-

Validado en más de 500 instalaciones en todo el mundo

-

Selección de componentes de grado militar

2. Tecnología a prueba de futuro

-

Firmware actualizable a nuevos estándares

-

Diseño modular para una fácil mejora

-

Garantía de compatibilidad con versiones anteriores

3. Fabricación sostenible

-

Sistemas servo de bajo consumo energético

-

Reducción de residuos consumibles

-

Materiales de construcción reciclables

-

Operación con baja huella de carbono

Conclusión: Transforme su producción hoy

Nuestro Robot de alta precisión representa la próxima generación de automatización industrial, ofreciendo a los fabricantes Precisión, confiabilidad y flexibilidad sin precedentes en sus operaciones. Ya sea que esté buscando Mejorar la calidad en el pulido de precisión, aumentar el rendimiento en las líneas de montaje, o mejorar la consistencia en los tratamientos de superficies, este Brazo robótico de 6 ejes con certificación CE Ofrece mejoras de rendimiento mensurables desde el primer día.

Con configuraciones personalizables para cumplir con los requisitos específicos de la aplicación y servicios de soporte integrales Para garantizar una integración perfecta, nuestra tecnología robótica de alta precisión proporciona una retorno de la inversión rápido mientras preparación para el futuro su infraestructura de automatización.

Dé el siguiente paso hacia la excelencia en la fabricación: comuníquese hoy con nuestros especialistas en automatización para obtener una consulta y demostración personalizadas.

SHENCHI ROBOT CO., LTD ofrece diferentes robots industriales con soluciones de automatización. Admitimos robots industriales que incluyen soldadura, pintura, manipulación, paletizado, doblado y pulido, bienvenido a contactarnos.

Robot Shenchi, más inteligente y más simple.

© Shenchi Company Todos los derechos reservados.