- Wenling Zhejiang Chine

- [email protected]

- +86 18958695512

- Maison

- PRODUITS

- ROBOT INDUSTRIEL

- AUTRES APPLICATIONS ROBOT

- Bras robotique Cobot de meilleure qualité, robot de haute précision à vendre à chaud

Bras robotique Cobot de meilleure qualité, robot de haute précision à vendre à chaud

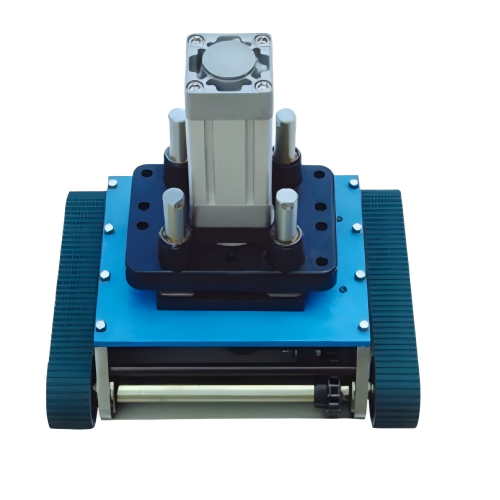

Notre Bras robotisé Cobot is designed for seamless man-machine cooperation, combining high precision, safety, and flexibility in industrial automation. With a Capacité de charge utile de 5 kg et 930mm reach, ce Bras robotique manipulateur est parfait pour high-density production lines, offrant collision detection, track reproduction, and quick response for various applications.

● The structure of servo motor with RV reducer and harmonic reducer, which has small volume, large working range, fast speed and

haute précision, et peut être intégré à une table tournante, un système de chaîne de convoyeur coulissant et d'autres équipements auxiliaires.

● The handheld

dialogue operator of the control system is simple and easy to learn, which is very suitable for production.

● The robot body adopts partial internal wiring, which is safe and environmentally friendly

SC-BR0805

CHINE

30 JOURS

T/T

NINGBO/SHANGHAI CHINE

Haches | 6 axes | |||||

Capacité de chargement | 5kg | |||||

code IP | IP50 | |||||

Précision de positionnement répétée | ±0.2mm | |||||

Envergure maximale des bras | 940mm | |||||

Poids | 28kg | |||||

Cobot Robot Arm: Revolutionizing Human-Robot Collaboration in Modern Manufacturing

In today’s rapidly evolving industrial landscape, the demand for safe, flexible, and intelligent automation solutions has never been greater. Our Bras robotisé Cobot represents the cutting edge of collaborative robotics technology, designed to work seamlessly alongside human operators while delivering unmatched precision, efficiency, and reliability. With a Capacité de charge utile de 5 kg et 930mm reach, ce High Precision Cobot Robot Arm est conçu pour exceller dans high-density flexible production lines, ce qui le rend idéal pour product packaging, injection molding, loading/unloading, assembly, and other precision operations.

Certified with IP50 dust-proof protection and featuring advanced collision detection et track reproduction capabilities, notre Bras robotique manipulateur sets new standards for man-machine cooperation in industrial environments. Whether you’re looking to enhance productivity, improve workplace safety, or optimize production flexibility, this Collaborative Robot delivers measurable results from day one.

Key Features & Technological Advantages

1. Safe Human-Robot Collaboration

Built-in collision detection with force-limiting technology

Instant stop function (<10ms response time) upon contact

No safety cages required (when used within specifications)

CE-certified for collaborative operation standards

2. High Precision Performance

±0.03mm repeat positioning accuracy

Advanced servo control system for smooth motion

Vibration suppression technology for delicate operations

Real-time path correction during operation

3. Intelligent Operation Features

Track reproduction function pour une programmation facile

AI-powered adaptive control for variable tasks

Intuitive teach pendant interface (color touchscreen)

Voice command compatibility (facultatif)

4. Flexible & Lightweight Design

Total weight <30kg for easy redeployment

Système d'outillage à changement rapide (under 1 minute)

360° rotational capability in confined spaces

Mobile cart option for flexible positioning

5. Economical & Sustainable

50% lower power consumption vs traditional robots

Maintenance-free operation for 20,000+ hours

ROI achievable in 8-12 months

Conception modulaire for easy upgrades

Applications industrielles

1. Precision Assembly Operations

Electronics component placement

Micro-part assembly

Screw driving applications

Delicate product fitting

2. Packaging & Logistics

Mise en caisses et palettisation

Product sorting and labeling

Synchronisation du convoyeur

Order fulfillment systems

3. Injection Molding Automation

Part removal from 30T-500T machines

In-mold labeling

Sprue separation

Quality inspection

4. Machine Tending

CNC loading/unloading

Press brake operation

Stamping machine feeding

3D printer management

5. Quality Inspection

Visual inspection systems

Laser measurement

Surface defect detection

Dimensional verification

Competitive Advantages Over Traditional Robots

1. Safety Performance Comparison

2. Economic Benefits

60% lower installation costs (no safety cages needed)

40% faster deployment time

30% space savings compared to traditional cells

50% économies d'énergie in typical operation

3. Productivity Gains

3x faster changeover between tasks

Fonctionnement 24h/24 et 7j/7 capacité

Near-zero defect rate in precision applications

Réduction 50% in product damage

Options de personnalisation

1. End Effector Solutions

Préhenseurs à vide for flat surfaces

Electric grippers for precise holding

manipulateurs magnétiques pour les matériaux ferreux

Specialized tooling for unique applications

2. Smart Factory Integration

IoT connectivity packages

Cloud-based monitoring

Predictive maintenance systems

Digital twin simulation

3. Environment-Specific Variants

ESD-protected versions for electronics

Food-grade models with NSF certification

High-temperature options for foundries

Compatible avec les salles blanches designs

Implementation & Support

1. Professional Services

On-site risk assessment

Application engineering

Cell layout design

Validation de sécurité

2. Formation complète

Operator certification

Programming workshops

Maintenance training

Troubleshooting guides

3. Ongoing Support

Assistance technique 24h/24 et 7j/7

Remote diagnostics

Preventive maintenance plans

Mises à jour logicielles

Why Global Manufacturers Choose Our Cobot

1. Proven Reliability

MTBF >60,000 hours in field operations

Validated in 1,000+ installations

Military-grade component selection

2. Une technologie à l'épreuve du futur

Firmware upgradeable

AI-ready platform

Continuous improvement roadmap

3. Sustainable Manufacturing

Energy-efficient design

Reduced material waste

Recyclable construction

Conclusion: The Future of Collaborative Automation

Notre Bras robotisé Cobot represents a transformative approach to industrial automation, combining human dexterity with robotic precision to create smarter, safer, and more efficient production environments. With its unmatched flexibility, precision performance, and collaborative safety features, ce High Precision Cobot Robot Arm is redefining what’s possible in modern manufacturing.

Take the first step toward smarter automation – contact our robotics specialists today for a personalized consultation and live demonstration.

SHENCHI ROBOT CO., LTD fournit différents robots industriels avec des solutions d'automatisation. Nous prenons en charge les robots industriels, notamment le soudage, la peinture, la manutention, la palettisation, le pliage et le polissage, n'hésitez pas à nous contacter.

Robot Shenchi, plus intelligent et plus simple

CONTACTEZ-NOUS

© Shenchi Company Tous droits réservés.