- Wenling zhejiang China

- [email protected]

- +86 18958695512

- Home

- PRODUCTS

- INDUSTRIAL ROBOT

- OTHER APPLICATIONS ROBOT

- Industrial robot High Quality Palletiz Stamp Robotic Arm

Industrial robot High Quality Palletiz Stamp Robotic Arm

we proudly present our high quality industrial robot – the Palletizing Stamping Robot, designed to revolutionize your production line. Our robot palletizing system combines precision engineering with cost-effective manufacturing, making it the ideal choice for stamping and material handling applications.

Applications:

• Metal stamping press automation

• Automotive component handling

• Heavy load palletizing

• CNC machine tending

Our industrial robot for palletizing stamping delivers professional-grade performance at an affordable price point, helping manufacturers boost productivity while maintaining quality standards.

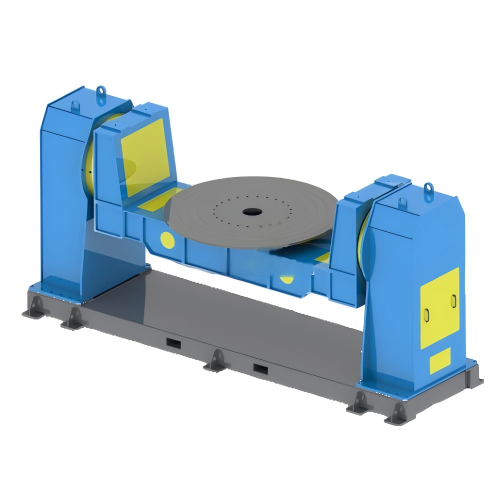

SC-CH1300

CHINA

30DAYS

T/T

NINGBO/SHANGHAI CHINA

Lifting stroke 40mm

motor N-90W 380V 50HZ

High-Performance Palletizing Stamping Robot – Your Trusted Automation Partner

we specialize in high-quality Palletizing Stamping Robots designed to optimize material handling, stamping, and palletizing operations in manufacturing facilities. Our Industrial Robot for Palletizing Stamping combines German engineering precision with competitive Chinese manufacturing costs, delivering unmatched efficiency, durability, and cost savings for factories worldwide.

With over [X] years of industry experience and [X,XXX] successful installations, our robots help manufacturers reduce labor costs, improve production speed, and enhance workplace safety. Whether you need automated palletizing, stamping press tending, or heavy-load material handling, our Robot Palletizing solutions provide high-speed, high-precision performance at an affordable price.

Why Choose Our Palletizing Stamping Robot?

1. Superior Performance & Precision

High-Speed Operation – Up to 1,500 cycles/hour for maximum productivity

Precision Handling – ±0.1mm repeatability for accurate part placement

Heavy Payload Capacity – From 50kg to 1,000kg (customizable)

Multi-Axis Flexibility – 4-axis & 6-axis models available

2. Robust & Durable Construction

Heavy-duty steel frame for long-term stability

IP67 protection (dustproof & waterproof) for harsh environments

Low-maintenance design with sealed bearings & lubrication-free joints

Overload & collision detection for safety

3. Smart Automation & Easy Integration

PLC & HMI control for easy programming

Compatible with major stamping presses & CNC machines

Vision-guided picking for precise part handling

IoT-ready for Industry 4.0 connectivity

4. Cost-Effective & Fast Delivery

30-50% lower cost than European/Japanese brands

60-day standard lead time

Low energy consumption (20% more efficient than competitors

Key Applications

1. Stamping Press Automation

Loading/unloading metal sheets into stamping machines

Precision part stacking after stamping

Reduces manual labor & improves safety

2. Palletizing & Material Handling

Box/bag stacking for logistics & warehousing

Heavy part transfer between production lines

AGV (Automated Guided Vehicle) integration

3. Automotive & Metal Fabrication

Car body part handling

Metal component palletizing

CNC machine tending

Competitive Advantages

Higher Payload Capacity – Stronger than similar-priced competitors

Faster Cycle Times – Optimized for high-efficiency production

Lower Maintenance – Sealed components reduce downtime

Easy Integration – Works with existing factory systems

Why Global Buyers Trust Us?

ISO 9001 & CE Certified Manufacturing

5-Year Warranty on Critical Components

24/7 Technical Support

500+ Satisfied Customers Worldwide

Customization Options

We offer tailored solutions including:

Special end-effectors (grippers, vacuum cups, magnetic handlers)

Custom reach & payload configurations

Automated vision systems for part recognition

Cleanroom-compatible models

SHENCHI ROBOT CO.,LTD provide different industrial robot with automation solutions . we support industrial robots including welding, painting, handling, palletizing, bending and polishing, welcome to contact us.

Shenchi robot ,More smart more simple

© Shenchi Company All right reserved.