- Wenling Zhejiang Kína

- [email protected]

- +86 18958695512

- Heim

- VÖRUR

- IÐNAÐARVÉLMENNI

- ÖNNUR FORRIT VÉLMENNI

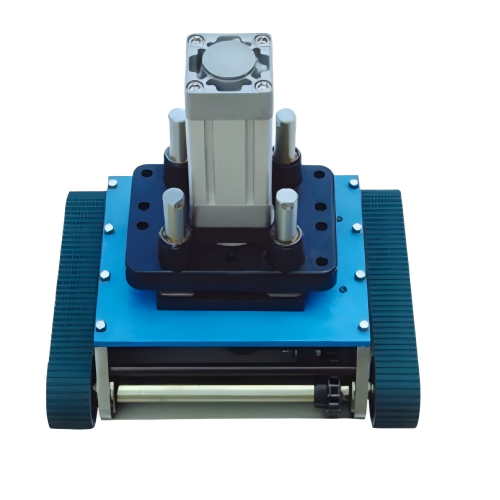

- Cobot vélmenniarmur besta gæði Heit selja hágæða vélmenni

Cobot vélmenniarmur besta gæði Heit selja hágæða vélmenni

Okkar Samvinnuvélmenni er hannað fyrir óaðfinnanlega samvinna manna og véla, sameina mikil nákvæmni, öryggi og sveigjanleiki í iðnaðarsjálfvirkni. Með 5 kg burðargeta og 930 mm teygjulengd, þetta Handvirkur vélmenni er fullkomið fyrir framleiðslulínur með mikilli þéttleika, tilboð árekstrargreining, slóðaendurgerð og skjót viðbrögð fyrir ýmis forrit.

● Uppbygging servómótors með RV-lækkunarbúnaði og harmonískri lækkunarbúnaði, sem hefur lítið rúmmál, stórt vinnusvið, mikinn hraða og

mikil nákvæmni og hægt er að samþætta það við snúningsborð, rennibrautarkeðjukerfi og annan hjálparbúnað.

● Handfesta tækið

Samræðustýring stjórnkerfisins er einföld og auðveld í nám, sem hentar mjög vel fyrir framleiðslu.

● Vélmennið notar að hluta innri raflögn, sem er öruggt og umhverfisvænt

SC-BR0805

Kína

30 DAGAR

T/T

NINGBO/SHANGHAI KÍNA

Öxar | 6 ás | |||||

Hleðslugeta | 5 kg | |||||

IP-kóði | IP50 | |||||

Endurtekin staðsetningarnákvæmni | ±0,2 mm | |||||

Hámarks armlengd | 940 mm | |||||

Þyngd | 28 kg | |||||

Samvinnuvélmenni: Gjörbyltir samvinnu manna og vélmenna í nútíma framleiðslu

Í ört vaxandi iðnaðarumhverfi nútímans hefur eftirspurn eftir öruggar, sveigjanlegar og snjallar sjálfvirknilausnir hefur aldrei verið meiri. Okkar Samvinnuvélmenni táknar fremstu brún samvinnuvélmennatækni, hannað til að vinna óaðfinnanlega með mannlegum rekstraraðilum á meðan það afhendir óviðjafnanleg nákvæmni, skilvirkni og áreiðanleikiMeð 5 kg burðargeta og 930 mm teygjulengd, þetta Há nákvæmni samvinnuvélmenni er hannað til að skara fram úr í sveigjanlegar framleiðslulínur með mikilli þéttleika, sem gerir það tilvalið fyrir vöruumbúðir, sprautumótun, hleðsla/afferming, samsetning og aðrar nákvæmnisaðgerðir.

Vottað með IP50 rykþétt vörn og með háþróuð árekstrargreining og getu til að endurskapa brautir, okkar Handvirkur vélmenni setur ný viðmið fyrir samvinna manna og véla í iðnaðarumhverfi. Hvort sem þú ert að leitast við að auka framleiðni, bæta öryggi á vinnustað eða hámarka sveigjanleika í framleiðslu, þá er þetta Samvinnuvélmenni skilar mælanlegum árangri frá fyrsta degi.

Helstu eiginleikar og tæknilegir kostir

1. Örugg samvinna manna og vélmenna

Innbyggð árekstrargreining með tækni sem takmarkar kraft

Stöðvunaraðgerð samstundis (<10ms svarstími) við snertingu

Engin öryggisbúr nauðsynleg (þegar notað innan forskrifta)

CE-vottað fyrir staðla fyrir samvinnuaðgerðir

2. Há nákvæmni

±0,03 mm nákvæmni endurtekinnar staðsetningar

Háþróað servóstýringarkerfi fyrir mjúka hreyfingu

Titringsdeyfingartækni fyrir viðkvæmar aðgerðir

Leiðrétting í rauntíma meðan á notkun stendur

3. Greindar rekstrareiginleikar

Sporafritunarvirkni fyrir auðvelda forritun

Aðlögunarstýring knúin með gervigreind fyrir breytileg verkefni

Innsæi kennsluviðmót (lit snertiskjár)

Samhæfni við raddskipanir (valfrjálst)

4. Sveigjanleg og létt hönnun

Heildarþyngd <30 kg til að auðvelda endurskipulagningu

Hraðskiptakerfi fyrir verkfæri (undir 1 mínútu)

360° snúningsgeta í lokuðum rýmum

Valkostur um farsímakörfu fyrir sveigjanlega staðsetningu

5. Hagkvæmt og sjálfbært

50% minni orkunotkun á móti hefðbundnum vélmennum

Viðhaldsfrí notkun í 20.000+ klukkustundir

Arðsemi fjárfestingar (ROI) sem hægt er að ná innan 8-12 mánaða

Mátunarhönnun fyrir auðveldar uppfærslur

Iðnaðarforrit

1. Nákvæm samsetningaraðgerðir

Staðsetning rafeindabúnaðar

Samsetning örhluta

Skrúfukeyrsluforrit

Viðkvæm varapassun

2. Pökkun og flutningar

Kassapakkning og palletering

Vöruflokkun og merkingar

Samstilling færibanda

Pöntunarafgreiðslukerfi

3. Sjálfvirkni sprautumótunar

Fjarlæging hluta úr 30T-500T vélum

Merking í mold

Aðskilnaður sprúa

Gæðaeftirlit

4. Vélþjónusta

CNC hleðsla/afhleðsla

Notkun pressubremsu

Fóðrun stimplunarvélarinnar

Stjórnun 3D prentara

5. Gæðaeftirlit

Sjónræn skoðunarkerfi

Leysigeislamæling

Greining á yfirborðsgöllum

Staðfesting á vídd

Samkeppnisforskot fram yfir hefðbundna vélmenni

1. Samanburður á öryggisafköstum

2. Efnahagslegur ávinningur

60% lækkar uppsetningarkostnað (engin öryggisbúr nauðsynleg)

40% hraðari dreifing tími

30% plásssparnaður samanborið við hefðbundnar frumur

Orkusparnaður 50% í dæmigerðri notkun

3. Framleiðniaukning

3x hraðari skipti á milli verkefna

Rekstur allan sólarhringinn hæfni

Nærri núll gallahlutfall í nákvæmniforritum

50% lækkun í vöruskemmdum

Sérstillingarvalkostir

1. Lausnir fyrir endaáhrif

Lofttæmisgriparar fyrir slétt yfirborð

Rafmagnsgriparar fyrir nákvæma hald

Segulmeðhöndlarar fyrir járnefni

Sérhæfð verkfæri fyrir einstök forrit

2. Snjall verksmiðjusamþætting

IoT tengingarpakkar

Skýjabundið eftirlit

Fyrirbyggjandi viðhaldskerfi

Stafræn tvíburahermun

3. Umhverfissértækar afbrigði

ESD-varðar útgáfur fyrir rafeindatækni

Matvælavænar gerðir með NSF vottun

Valkostir við háan hita fyrir steypustöðvar

Samhæft við hreinrými hönnun

Innleiðing og stuðningur

1. Fagþjónusta

Áhættumat á staðnum

Umsóknarverkfræði

Hönnun frumuuppsetningar

Öryggisstaðfesting

2. Ítarleg þjálfun

Vottun rekstraraðila

Forritunarnámskeið

Viðhaldsþjálfun

Leiðbeiningar um bilanaleit

3. Áframhaldandi stuðningur

Tæknileg aðstoð allan sólarhringinn

Fjargreining

Fyrirbyggjandi viðhaldsáætlanir

Hugbúnaðaruppfærslur

Af hverju alþjóðlegir framleiðendur velja samvinnuvélina okkar

1. Sannað áreiðanleiki

MTBF >60.000 klukkustundir í vettvangsaðgerðum

Staðfest í yfir 1.000 uppsetningum

Val á íhlutum í hernaðarflokki

2. Framtíðarvæn tækni

Hægt er að uppfæra vélbúnað

Pallur tilbúinn fyrir gervigreind

Leiðarvísir fyrir stöðugar umbætur

3. Sjálfbær framleiðsla

Orkusparandi hönnun

Minnkuð efnisúrgangur

Endurvinnanleg smíði

Niðurstaða: Framtíð samvinnu sjálfvirkni

Okkar Samvinnuvélmenni táknar umbreytandi nálgun á iðnaðarsjálfvirkni, sem sameinar Mannleg handlagni með vélrænni nákvæmni til að skapa snjallara, öruggara og skilvirkara framleiðsluumhverfi. Með því Óviðjafnanlegur sveigjanleiki, nákvæmni og samvinnuöryggiseiginleikar, þetta Há nákvæmni samvinnuvélmenni er að endurskilgreina hvað er mögulegt í nútíma framleiðslu.

Taktu fyrsta skrefið í átt að snjallari sjálfvirkni – hafðu samband við vélfærafræðinga okkar í dag til að fá persónulega ráðgjöf og kynningu.

SHENCHI ROBOT CO., LTD býður upp á ýmsar iðnaðarvélmenni með sjálfvirknilausnum. Við styðjum iðnaðarvélmenni eins og suðu, málun, meðhöndlun, palleteringu, beygju og fægingu, velkomið að hafa samband við okkur.

Shenchi vélmenni, snjallara og einfaldara

HAFIÐ SAMBAND VIÐ OKKUR

© Shenchi Company Allur réttur áskilinn.