- Wenling Zhejiang Cina

- [email protected]

- +86 18958695512

- Casa

- PRODOTTI

- ROBOT INDUSTRIALE

- ALTRE APPLICAZIONI ROBOT

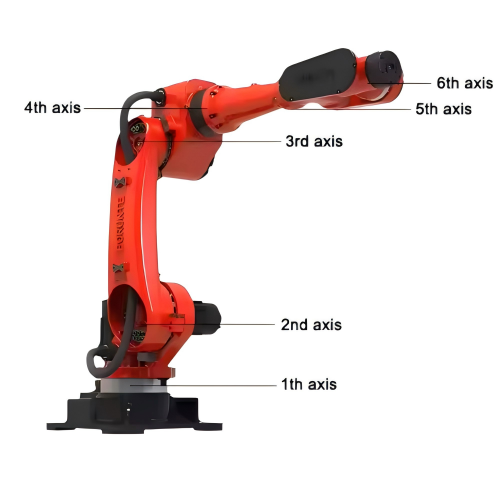

- Robot articolato, braccio robotico industriale a 6 assi di alta qualità

Robot articolato, braccio robotico industriale a 6 assi di alta qualità

Poiché le esigenze di produzione diventano sempre più complesse, il nostro Robot articolato emerge come la soluzione di automazione definitiva per la precisione Punzonatrice E Fusione a pressione applicazioni. Questo Robot ad alta precisione offre prestazioni ineguagliabili, combinando la durevolezza di livello industriale con la tecnologia all'avanguardia per trasformare la tua linea di produzione.

Applicazioni comprovate nel settore:

Stampaggio di precisione di metalli e punzonatura

Assistenza alla macchina per pressofusione con capacità di resistenza al calore

Movimentazione automatizzata dei materiali per processi di punzonatura

Controllo di qualità integrato nelle operazioni di fusione

SC-BR1820

CINA

30 GIORNI

Da domani a domani

NINGBO/SHANGHAI CINA

Robot articolato: la soluzione di automazione definitiva per applicazioni di punzonatura e pressofusione

Nell'attuale panorama competitivo della produzione, precisione, efficienza e affidabilità sono fondamentali per mantenere un vantaggio competitivo. Le nostre tecnologie all'avanguardia Robot articolato rappresenta l'apice della tecnologia di automazione industriale, specificamente progettato per eccellere in applicazioni impegnative come Punzonatrice operazioni e Fusione a pressione processi. Come fornitore leader di Soluzioni di progetti robotici, forniamo automazione all'avanguardia che trasforma le linee di produzione in molteplici settori.

Questa guida completa esplora come il nostro Braccio robotico industriale Rivoluziona i processi produttivi grazie alla sua precisione ineguagliabile, alla sua struttura robusta e alle sue capacità di automazione intelligente. Che operiate nel settore automobilistico, nella lavorazione dei metalli o nella fusione di precisione, il nostro Robot ad alta precisione è progettato per aumentare l'efficienza produttiva riducendo al contempo i costi operativi.

Specifiche tecniche e caratteristiche principali del robot articolato

1. Ingegneria di precisione per applicazioni impegnative

Design articolato a 6 assi per la massima flessibilità nei movimenti complessi

Ripetibilità ±0,02 mm garantire operazioni coerenti e ad alta precisione

Sistema di controllo servo avanzato per un movimento fluido e senza vibrazioni

Protezione con grado di protezione IP67 contro polvere, liquidi e ambienti industriali difficili

2. Prestazioni robuste per applicazioni pesanti

Capacità di carico utile che vanno da 5 kg a 50 kg per soddisfare diverse esigenze di produzione

Funzionamento ad alta velocità con tempi di ciclo ottimizzati per i processi di punzonatura e fusione

Costruzione resistente agli urti per resistere ai rigori delle operazioni della punzonatrice

Materiali resistenti al calore per prestazioni affidabili in ambienti di fusione a pressione

3. Tecnologie di automazione intelligente

Rilevamento della forza integrato per il controllo adattivo della pressione nelle applicazioni di fusione

Monitoraggio della posizione in tempo reale con sistemi di codifica avanzati

Rilevamento delle collisioni e funzionalità di recupero automatico

Integrazione del controllore logico programmabile (PLC) per un coordinamento senza interruzioni della linea di produzione

4. Design ergonomico e integrazione

Ingombro compatto consente di risparmiare prezioso spazio sul pavimento negli impianti di produzione

Sistema di attacco terminale a cambio rapido per un rapido cambio di utensili

Sistemi di sicurezza preinstallati incluso arresto di emergenza e monitoraggio della velocità

Funzionamento a risparmio energetico con tecnologia di frenata rigenerativa

Applicazioni specifiche del settore

1. Automazione della punzonatrice

Stampaggio di precisione dei metalli con applicazione di forza costante

Perforazione ad alta velocità per la fabbricazione di lamiere

Operazioni di stampo progressivo con allineamento perfetto

Movimentazione automatizzata dei materiali prima e dopo i processi di punzonatura

2. Soluzioni per fusione a pressione

Addetto alla macchina per pressofusione con posizionamento preciso delle parti

Manipolazione di metalli fusi con effettori terminali resistenti al calore

Fusione, rifinitura e finitura operazioni

Controllo di qualità integrato nel processo di fusione

3. Ulteriori applicazioni industriali

Produzione di componenti automobilistici

Produzione di componenti aerospaziali

Fabbricazione di contenitori per elettronica

Assemblaggio di attrezzature industriali

Opzioni di integrazione del sistema

1. Cella completa per punzonatura

Chiavi in mano Soluzioni di progetti robotici per applicazioni di punzonatura

Include robot, cambiautensili, sistemi di movimentazione materiali e recinzioni di sicurezza

Routine preprogrammate per operazioni di punzonatura comuni

Monitoraggio della forza per la garanzia della qualità

2. Pacchetto di automazione per la pressofusione

Specializzato Braccio robotico industriale configurazione per ambienti di fonderia

Sistemi di schermatura termica e raffreddamento

Sistemi di visione integrati per l'ispezione delle fusioni

Opzioni di movimentazione automatizzata della siviera

3. Soluzioni di produzione flessibili

Celle di lavoro coordinate multi-robot

Trasferimento automatizzato delle parti tra i processi

Connettività della fabbrica intelligente (pronta per l'Industria 4.0)

Monitoraggio e diagnostica a distanza

Vantaggi competitivi

1. Precisione e qualità senza pari

Il funzionamento coerente elimina l'errore umano

Capacità di microregolazione per un perfetto allineamento delle parti

Registrazione dei dati per la tracciabilità della qualità

Riduzione dei tassi di scarto e degli sprechi di materiale

2. Miglioramenti della produttività

Operatività 24 ore su 24, 7 giorni su 7 capacità

30-50% più veloce rispetto alle operazioni manuali

Operazioni multiprocesso simultanee

Cambio rapido tra cicli di produzione

3. Risparmio sui costi e ROI

Riduzione fino a 60% nei costi del lavoro

Minore consumo energetico rispetto ai sistemi convenzionali

Riduzione dell'usura degli utensili grazie al funzionamento preciso

Requisiti minimi di manutenzione

4. Tecnologia a prova di futuro

Software aggiornabile per nuove applicazioni

Design modulare per una facile espansione

Connettività IoT per la manutenzione predittiva

Compatibilità con gli standard industriali emergenti

Supporto tecnico e assistenza

La nostra rete di supporto globale garantisce la tua Robot ad alta precisione funziona al massimo delle prestazioni:

Installazione in loco e messa in servizio

Formazione completa degli operatori programmi

Manutenzione preventiva contratti

Diagnostica remota e risoluzione dei problemi

Ricambi dedicati inventario

Casi di studio e storie di successo

Caso di studio 1: Impianto di stampaggio automobilistico

Implementazione del nostro Robot articolato in un'applicazione di punzonatura si è ottenuto:

Aumento di 40% nella produzione giornaliera

Riduzione del tasso di difettosità da 3% a 0,1%

ROI raggiunto in soli 7 mesi

Caso di studio 2: fonderia di alluminio

Integrazione della nostra Braccio robotico industriale per la fusione a pressione ha prodotto:

Riduzione 50% nei costi del lavoro

Diminuzione 35% nei rifiuti materiali

Miglioramento della sicurezza dei lavoratori allontanando il personale dalle aree pericolose

Conclusione: trasforma la tua produzione oggi stesso

Nostro Robot articolato rappresenta la perfetta fusione di precisione, potenza e flessibilità per la produzione moderna. Come specialisti in Soluzioni di progetti roboticiforniamo pacchetti di automazione completi, studiati su misura per le vostre specifiche esigenze nelle applicazioni di punzonatura e pressofusione.

Con il suo alta precisione capacità, costruzione robusta e funzioni di automazione intelligenti, questo Braccio robotico industriale apporta miglioramenti misurabili in termini di qualità, produttività e redditività in numerosi settori.

Fai il primo passo verso l'eccellenza produttiva: contatta oggi stesso i nostri specialisti dell'automazione per una consulenza e una dimostrazione personalizzate.

SHENCHI ROBOT CO.,LTD fornisce diversi robot industriali con soluzioni di automazione. Forniamo assistenza per robot industriali, tra cui saldatura, verniciatura, movimentazione, pallettizzazione, piegatura e lucidatura. Non esitate a contattarci.

Robot Shenchi, più intelligente, più semplice

© Shenchi Company Tutti i diritti riservati.