- 中国浙江省温嶺市

- [email protected]

- +86 18958695512

- 家

- 製品

- 産業用ロボット

- その他の用途ロボット

- ページ

- CNCローディングタスクに最適な10kgペイロード産業用ロボット

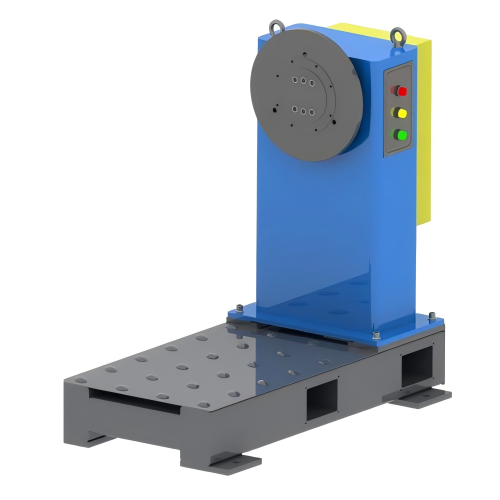

CNCローディングタスクに最適な10kgペイロード産業用ロボット

最大荷重は 10kgアームの長さは1500mmです。軽量アーム設計、コンパクトでシンプルな機械構造、高速移動状態では、小さな作業スペースで柔軟な作業を実行でき、柔軟な生産のニーズを満たします。 6度の柔軟性があります。塗装、溶接、成形、スタンピング、鍛造、ハンドリング、ローディング、組み立てなどに適しています。HC制御システムを採用しています。200T〜600Tの射出成形機の範囲に適しています。保護等級はlP54に達します。防塵および防水。繰り返し位置決め精度は±0.05mmです。

RV減速機と高調波減速機を備えたサーボモーターの構造は、体積が小さく、動作範囲が広く、速度が速く、

高精度で、ターンテーブル、スライドコンベアチェーンシステムなどの補助装置と統合できます。

制御システムのハンドヘルド対話型オペレータはシンプルで使いやすく、生産現場に最適です。ロボット本体は部分的に内部配線を採用しており、安全で環境に優しいです。

SC-BR1510

中国

30日間

ありがとう

中国寧波/上海

斧 | 6軸 | |||||

積載能力 | 20kg | |||||

IPコード | 本体: IP50 手首: IP54 | |||||

繰り返し位置決め精度 | ±0.05mm | |||||

最大腕の長さ | 1500mm | |||||

重さ | 152kg | |||||

10kg可搬重量の産業用ロボット – コンパクトな作業スペースを実現する精度、スピード、柔軟性

今日の競争の激しい製造業において、自動化は効率性の向上、コスト削減、そして高品質な生産基準の維持に不可欠です。 10kgペイロード産業用ロボット 実現するために設計されています 高速、柔軟、かつ正確な自動化 で コンパクトなワークスペース次のような産業に最適です。 自動車、電子機器、プラスチック、金属加工.

と 6自由度(DOF), ±0.05mmの繰り返し位置決め精度、 そして CEおよびRoHS準拠認証、 これ ロボットアーム 保証する 信頼性の高い高性能な操作 次のような用途では 塗装、溶接、成形、打ち抜き、鍛造、ハンドリング、積み込み、組み立て.

高度な HC制御システム、 これ 産業用ロボット に最適です 射出成形機(200T-600T) その他の厳しい産業環境にも対応可能です。 IP54保護等級 保証する 防塵・防水性能過酷な条件でも耐久性を発揮します。

10kgペイロード産業用ロボットの主な特徴

1. 高速かつ高精度なパフォーマンス

10kgの積載量 – 中程度の自動化タスクに最適です。

±0.05mmの繰り返し位置決め精度 – 保証 超精密な操作 組み立て、溶接、取り扱いにおいて。

高速動作 – 最適化 高速サイクルタイム生産効率が向上します。

2. コンパクトで柔軟な設計

6軸ロボットアーム – 有効にする 多方向の動き 複雑なタスク向け。

コンパクトなフットプリント – シームレスにフィット 狭い生産スペース.

広い作業範囲 – 位置を変更せずに複数のワークステーションをカバーします。

3. 高度なHC制御システム

ユーザーフレンドリーなプログラミング – サポート ペンダントとオフラインプログラミングを教える.

シームレスな統合 – 対応機種 PLC、CNC、スマートファクトリーシステム(インダストリー4.0).

リアルタイム監視と診断 – 保証 予測メンテナンスと最小限のダウンタイム.

4. 堅牢で信頼性の高い構造

IP54保護 – 耐性 ほこり、水しぶき、産業廃棄物.

高強度アルミニウムおよびスチール部品 – 保証 長期耐久性.

メンテナンスの手間が少ない設計 – 運用コストを削減します。

5. 安全性とコンプライアンスの認証

CE認証 – ミーツ 欧州の安全性と性能基準.

RoHS準拠 – 有害物質を含まないため、 環境に優しい操作.

6. 多様な用途に対応

塗装・コーティング – 実現する 一貫した高品質の仕上げ.

溶接(アーク/スポット/MIG/TIG) – 保証 欠陥を最小限に抑えた精密溶接.

成形とスタンピング – 自動化 射出成形(200T-600T機) および金属成形。

材料処理と組み立て – ハンドル 高効率の小型から中型の部品.

当社の 10kg ペイロード産業用ロボットを選ぶ理由

生産性の向上

サイクルタイムを短縮 と 高速動作.

人的エラーを最小限に抑える 反復的なタスクにおいて。

スループットの向上 と 24時間365日の運用能力.

コスト効率の高い自動化

人件費を削減 手動操作を置き換えることによって。

材料の無駄を削減 と 超精密なハンドリング.

ダウンタイムの短縮 と 信頼性が高く、メンテナンスの手間が少ないパフォーマンス.

未来を見据えたテクノロジー

IoT対応 のために リモート監視とデータ分析.

協働ロボット(コボット)向けに拡張可能.

アップグレード可能なソフトウェア 進化する業界のニーズに対応します。

産業アプリケーション

1. 自動車製造

車体部品の精密溶接.

小型部品(センサー、ギア、ファスナー)の取り扱い.

塗装およびコーティング用途.

2. 電子機器および消費財

PCBアセンブリとテスト.

スマートフォンや家電製品の製造における小型部品のハンドリング.

3. プラスチックと射出成形

200T~600T射出成形機からの自動部品取り出し.

プラスチック部品の仕分け、積み重ね、梱包.

4. 金属プレス加工と鍛造

プレス機への金属板の積み込み/積み下ろし.

小型金属部品の精密鍛造.

5. 一般的な製造および組立

ピックアンドプレース操作.

ねじ締め、接着、精密組立.

結論:コンパクトな自動化のための賢い選択

私たちの 10kgペイロード産業用ロボット メーカーにとって最適なソリューションです スピード、精度、柔軟性 で コンパクトなワークスペース. のために 溶接、塗装、成形、または組み立て、 これ ロボットアーム 配信 高い効率、信頼性、国際基準への準拠.

これを統合することで 産業用ロボット 生産ラインに導入すれば、 生産性の向上、コストの削減、競争力の維持 世界市場で。

今すぐお問い合わせください 私たちの 10kgペイロード産業用ロボット 製造プロセスを変革できます!

SHENCHI ROBOT CO.,LTDは、自動化ソリューションを備えたさまざまな産業用ロボットを提供しています。当社は、溶接、塗装、ハンドリング、パレタイジング、曲げ、研磨などの産業用ロボットをサポートしていますので、お気軽にお問い合わせください。

神池ロボット、よりスマートに、よりシンプルに

© 神池カンパニー 無断複写・転載を禁じます。