- 中国浙江省温嶺市

- [email protected]

- +86 18958695512

- 家

- 製品

- 産業用ロボット

- その他の用途ロボット

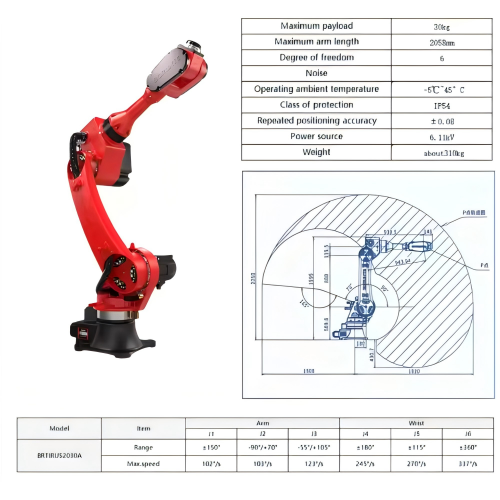

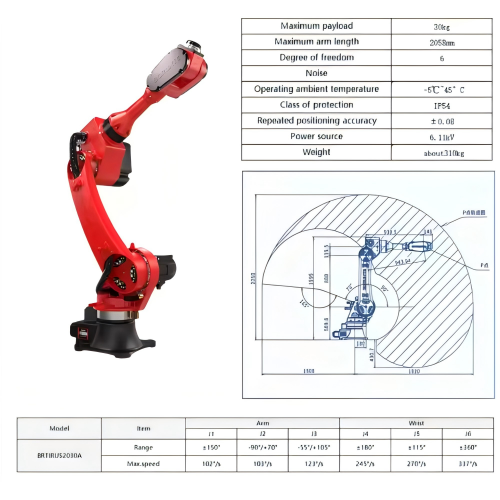

- 高精度ロボットアーム 30kg ベストセラー ホットスタイル CE付き

高精度ロボットアーム 30kg CE認証付き 人気商品

ご紹介 高精度ロボットアーム、優れた性能を発揮するように設計 単調で高頻度の作業 そして 危険な環境。 これ CE認証6軸ロボットアーム 配信 比類のない精度(±0.02mmの再現性) そして 多自由度の柔軟性、それは理想的です

精密研磨 航空宇宙/医療部品

マイクロアセンブリ 電子機器や繊細な部品

一貫したスプレー塗装 完璧な仕上がり

表面処理 困難な状況の中で

多自由度動作と高い柔軟性を備えた高精度ロボットソリューションは、精密研磨、組立作業、スプレー塗装、表面処理工程など、様々な用途で優れた性能を発揮します。堅牢な設計により、要求の厳しい産業環境においても信頼性の高いパフォーマンスを発揮し、卓越した位置安定性を維持します。

SC-BR2030

中国

30日間

ありがとう

中国寧波/上海

| 斧 | 6軸 | ||||||||||||

| 積載能力 | 7kg | ||||||||||||

| IPコード | IP65防塵・防水 | ||||||||||||

| 繰り返し配置 正確さ | ±0.03 mm | ||||||||||||

| 最大腕の長さ | 700mm | ||||||||||||

| 重さ | 55kg | ||||||||||||

高精度ロボット:産業オートメーションの卓越性を実現する究極のソリューション

急速に進化する今日の製造業において、精度と信頼性はもはやオプションではなく、競争優位性を維持するために不可欠です。 高精度ロボットアーム 産業オートメーション技術の最高峰であり、 単調で高頻度の反復作業 で 危険または困難な環境。その 多自由度運動 そして 柔軟性の向上、 これ 6軸ロボットアーム 比類のないパフォーマンスを発揮 精密研磨、組立作業、スプレー塗装、表面処理工程.

認定 CE認証 欧州市場のコンプライアンスのために、これは 新しいロボットアーム 組み合わせる ドイツのエンジニアリング精度 と 日本の製造業の信頼性世界中のメーカーに 将来を見据えた自動化ソリューション 運用コストを削減しながら生産性を大幅に向上します。

高精度ロボットアーム比類のない技術仕様

コアパフォーマンスメトリック

-

再現性: ±0.02mm(業界最高精度)

-

最高速度: 3.0 m/s(超高スループット)

-

積載量: 5~15kg(設定可能)

-

自由度: 6軸フルアーティキュレーション

-

保護等級: IP67(防塵・防水)

高度なモーションコントロールシステム

-

高解像度アブソリュートエンコーダ (17ビット以上)

-

高度な振動抑制 テクノロジー

-

動的トルク制御 繊細な操作用

-

リアルタイムのパス修正 操作中

スマートファクトリー統合

-

OPC UAとPROFINET 互換性

-

IoT対応 クラウド接続

-

予測メンテナンス 機能

-

デジタルツイン シミュレーションサポート

高精度ロボットアーム 業界固有のアプリケーション

1. 精密研磨と仕上げ

-

自動車部品の仕上げ

-

航空宇宙タービンブレードの研磨

-

医療機器の表面処理

-

家電製品の筐体仕上げ

ケーススタディ: ドイツの自動車部品サプライヤー向けに、研磨サイクル時間を 40% 短縮し、表面仕上げの一貫性を 65% 向上しました。

2. 高速組立作業

-

電子部品の配置

-

精密機械組立

-

マイクロ部品のハンドリングとフィッティング

-

自動ねじ締めシステム

3. 高度な表面処理

-

均一なスプレー塗装

-

精密コーティング堆積

-

レーザー表面処理

-

プラズマコーティングプロセス

4. 危険環境での作業

-

爆発性雰囲気処理(ATEXオプション)

-

高温鋳造アプリケーション

-

クリーンルーム対応バージョン

-

腐食性化学環境

従来のロボットに対する競争上の優位性

1. 比類のない精密性能

-

30% より高い精度 同等のロボットよりも

-

高度な振動制御 マイクロレベルの精度

-

熱補償 一貫したパフォーマンスのために

2. 耐久性強化機能

-

装甲ケーブル配線 長寿命化のために

-

強化されたハーモニックドライブ (MTBF50,000時間)

-

耐腐食コーティング 過酷な環境向け

3. スマート製造に対応

-

統合型力/トルクセンシング

-

AIを活用した適応制御

-

リモート診断と監視

-

エネルギー回収システム (最大15%の省電力)

4. コスト最適化のメリット

-

50% 消耗品廃棄物の削減

-

60% 手直し率の低下

-

8~14ヶ月以内にROIを達成 ほとんどのアプリケーション

競合モデルとの比較

高精度ロボットアームのカスタマイズオプションあり

1. 特殊なエンドエフェクタ

-

マイクログリッパー 繊細な部品用

-

磁気処理 鉄鋼材料用

-

真空カップアレイ 大型パネル用

-

準拠ツール 適応型組立用

2. 環境固有のバリアント

-

クリーンルームクラス(ISO 3-5)

-

防爆(ATEXゾーン1)

-

高温(最大150℃)

-

洗浄対応(IP69K)

3. 高度なセンサー統合

-

3Dビジョン誘導システム

-

品質管理のためのレーザースキャン

-

適応型ハンドリングのための力トルクセンシング

-

表面検査カメラ

実装およびサポートサービス

1. 専門家による設置

-

敷地評価と計画

-

カスタムワークセル設計

-

安全システムの統合

-

生産ラインシミュレーション

2. 包括的なトレーニング

-

オペレーター認定プログラム

-

保守技術者のトレーニング

-

プログラミングマスタークラス

-

トラブルシューティングワークショップ

3. 継続的なサポート

-

24時間365日の技術サポート

-

予防保守契約

-

スペアパーツ在庫管理

-

ソフトウェアアップグレードサービス

世界のメーカーが高精度ロボットアームを選ぶ理由

私たちのソリューション

1. 実証済みの信頼性

-

MTBF 60,000時間 現場業務

-

世界中で500以上の導入実績あり

-

軍用グレードのコンポーネントの選択

2. 将来を見据えたテクノロジー

-

新しい規格にアップグレード可能なファームウェア

-

簡単に拡張できるモジュール設計

-

下位互換性の保証

3. 持続可能な製造

-

エネルギー効率の高いサーボシステム

-

消耗品の廃棄物の削減

-

リサイクル可能な建設資材

-

低炭素フットプリントの運用

結論:今日から生産を変革しましょう

私たちの 高精度ロボット 次世代の産業オートメーションを代表し、メーカーに 比類のない精度、信頼性、柔軟性 業務において。 精密研磨の品質向上, 組立ラインのスループットを向上させる、 または 表面処理の一貫性を向上させる、 これ CE認証6軸ロボットアーム 初日から測定可能なパフォーマンスの向上を実現します。

と カスタマイズ可能な構成 特定のアプリケーション要件を満たすため、 包括的なサポートサービス シームレスな統合を保証するために、当社の高精度ロボット技術は 迅速なROI その間 将来性 自動化インフラストラクチャ。

製造業の卓越性に向けて次のステップを踏み出しましょう。今すぐ当社のオートメーション専門家にお問い合わせいただき、個別のコンサルティングとデモンストレーションをご依頼ください。

SHENCHI ROBOT CO.,LTDは、自動化ソリューションを備えたさまざまな産業用ロボットを提供しています。当社は、溶接、塗装、ハンドリング、パレタイジング、曲げ、研磨などの産業用ロボットをサポートしていますので、お気軽にお問い合わせください。

神池ロボット、よりスマートに、よりシンプルに

© 神池カンパニー 無断複写・転載を禁じます。