- 中国浙江省温嶺市

- [email protected]

- +86 18958695512

溶接ロボット 2001mmの到達距離を持つ便利なハンドリングロボット

- プロとして 溶接ロボット 15年以上の経験を持つメーカーとして、私たちは 費用対効果の高い自動化ソリューション アーク溶接、スポット溶接、レーザー溶接用途向け。当社のロボットは 一貫した高品質の溶接 生産コストを大幅に削減します。

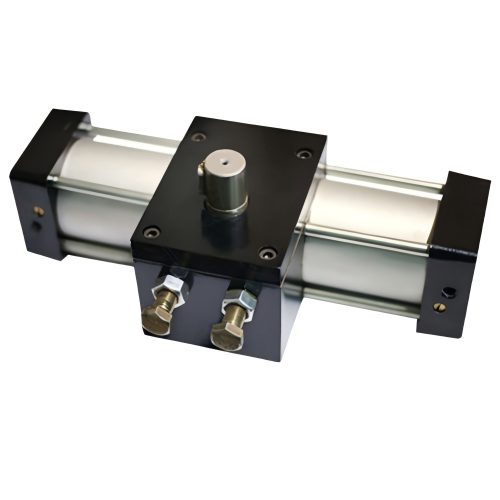

- 機械構造はシンプルでコンパクト。地上設置と逆設置を選択できます。

- 溶接ロボットのリーチは約2メートルです。広い作業スペースは、大型製品の溶接作業に適しています。

- 高速動作、高い繰り返し位置決め精度、溶接、積み込みと積み下ろし、ハンドリング、組み立てなどの用途に適しています。

- 繰り返し位置決め精度: ±0.05mm

- アームスパン:2001mm

QJR6-3

中国

30日間

ありがとう

中国寧波/上海

| モデル | QJR6-3 | |

| 軸番号 | 6 | |

| ペイロード | 6kg | |

| 繰り返し配置 | ±0.05mm | |

| 最大腕幅 | 2001mm | |

高性能溶接ロボット:精密溶接のための費用対効果の高い自動化ソリューション

競争の激しい今日の製造業において、生産効率を最適化しながら、一貫した高品質の溶接を実現することは、これまで以上に重要になっています。15年以上にわたり自動溶接システムを専門とする産業用ロボットのリーディングメーカーとして、当社は、プロフェッショナルグレードの溶接性能を卓越した価値で実現する、高度な溶接ロボットシリーズを開発しました。

当社の溶接ロボットは、精密アーク溶接技術とインテリジェントな自動化を融合させ、自動車製造から重機製造まで、幅広い業界に包括的なプロジェクトベースのソリューションを提供します。当社の強みは、あらゆる生産環境に合わせてシステムをカスタマイズできることです。大量生産の自動車生産ラインから、混合製品の溶接を必要とする専門工場まで、あらゆる生産環境に対応します。

セクション1:製品概要 – 溶接ロボットシリーズ

主な仕様とパフォーマンス上の利点

作業範囲: 1400~2100mmのリーチ(完全にカスタマイズ可能)

再現性: ±0.05mmで完璧な溶接継ぎ目トラッキングを実現

最高速度: 最適な移動速度は1.8m/s

ペイロード: 6~20kg (トーチ + ケーブル)

保護レベル: 標準 IP54 (IP67 オプション)

温度範囲: -10°C~45°Cで動作

コスト削減の価値提案

✔ 35%はヨーロッパの同等品よりも手頃な価格

✔ 動作中のエネルギー消費量 <5.2kWh

✔ 設計寿命は5年、年間故障率は1%未満

✔ 25% 精密溶接による材料節約

セクション2:製造の専門知識と品質保証

2.1 最先端の生産設備

当社の 60,000 平方メートルのスマート製造キャンパスの特徴:

自動品質管理を備えたロボット組立ライン

性能検証のための専用溶接試験セル

気候制御試験室

3D溶接パスシミュレーションステーション

2.2 厳格な品質プロトコル

ISO 9001:2015認証生産

各ユニット100時間連続動作テスト

CE、UL、CR認証機能

完全な材料トレーサビリティシステム

セクション3:完全なプロジェクト実施能力

3.1 環境適応型ソリューション

当社は厳しい条件に対応するシステムを設計します。

高粉塵環境(強化保護システム)

湿気の多い環境(耐腐食性部品)

爆発性雰囲気(ATEX認証モデルあり)

極端な温度変化(特別な冷却/加熱オプション)

3.2 カスタム構成オプション

アプリケーション固有のトーチマウント

統合シーム追跡システム(レーザー/ビジョン)

複雑な形状に対応する多軸ポジショナー

さまざまな材料に対応するワイヤ供給システム

3.3 ターンキー溶接セル

当社は以下を含む包括的なソリューションを提供します:

溶接電源(MIG/MAG、TIG、スポット)

ワークピースポジショナー

煙抽出システム

安全囲いとライトカーテン

セクション4:業界固有のアプリケーション

4.1 自動車製造

ボディインホワイトスポット溶接

サブフレームMIG溶接

排気システムTIG溶接

4.2 重機

構造部品の溶接

バケットとブレードの製造

フレームアセンブリソリューション

4.3 パイプと圧力容器

円周溶接システム

縦方向シーム溶接

ノズルとフランジの溶接

第5章:世界中のお客様が当社を選ぶ理由

5.1 比類のない価値の優位性

45%は競合他社よりもTCOが低い

3年間の包括的な保証

15か国での現地技術サポート

5.2 エンジニアリングサポートサービス

無料の溶接プロセス分析

現場での設置とトレーニング

リモート診断機能

5.3 実証済みの成功事例

米国重機メーカー:40%の生産性向上

ドイツの自動車部品サプライヤー:30%の材料コスト削減

中東の油田機器メーカー:砂漠に最適化されたシステム

結論: 信頼できる溶接自動化パートナー

当社の溶接ロボットは、産業グレードの性能と手頃な価格を兼ね備え、包括的なプロジェクト遂行能力を備えています。小ロット生産から大量生産ラインまで、お客様のニーズに合わせたソリューションをご提供いたします。

初回購入者向け特別オファー:

無料の溶接プロセス評価

割引スペアパーツパッケージ

延長保証オプション

SHENCHI ROBOT CO.,LTDは、自動化ソリューションを備えたさまざまな産業用ロボットを提供しています。当社は、溶接、塗装、ハンドリング、パレタイジング、曲げ、研磨などの産業用ロボットをサポートしていますので、お気軽にお問い合わせください。

神池ロボット、よりスマートに、よりシンプルに

© 神池カンパニー 無断複写・転載を禁じます。