- 원링 절강 중국

- [email protected]

- +86 18958695512

CNC 로딩 작업에 적합한 10kg 페이로드 산업용 로봇

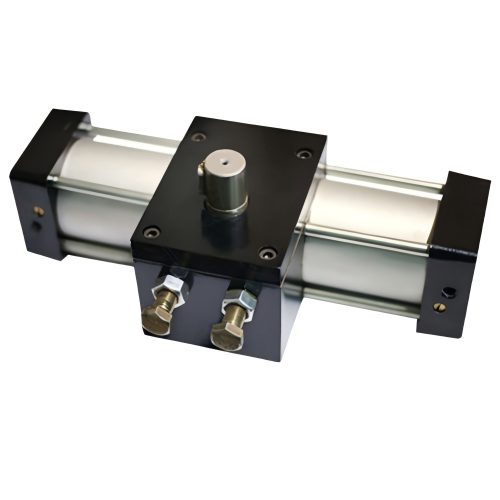

최대 하중은 10kg, 암 길이는 1500mm입니다. 가벼운 암 디자인, 컴팩트하고 간단한 기계 구조, 고속 이동 상태에서 작은 작업 공간에서 유연한 작업을 수행할 수 있어 유연한 생산 요구를 충족합니다. 6단계의 유연성을 제공합니다. 도장, 용접, 성형, 스탬핑, 단조, 취급, 적재, 조립 등에 적합합니다. HC 제어 시스템을 채택했습니다. 200T~600T 범위의 사출 성형기에 적합합니다. 보호 등급은 LP54입니다. 방진 및 방수 기능을 갖추고 있습니다. 반복 위치 정확도는 ±0.05mm입니다.

작은 체적, 넓은 작업 범위, 빠른 속도를 갖는 RV 감속기와 하모닉 감속기를 사용한 서보 모터의 구조

정밀도가 높고 턴테이블, 슬라이드 컨베이어 체인 시스템 및 기타 보조 장비와 통합이 가능합니다.

제어 시스템의 핸드헬드 대화형 오퍼레이터는 간단하고 배우기 쉬워 생산에 매우 적합합니다. 로봇 본체는 부분 내부 배선을 채택하여 안전하고 친환경적입니다.

SC-BR1510

중국

30일

티/티

닝보/상하이 중국

도끼 | 6축 | |||||

적재 능력 | 20kg | |||||

IP 코드 | 본체: IP50 손목: IP54 | |||||

반복 위치 정확도 | ±0.05mm | |||||

최대 팔 길이 | 1500mm | |||||

무게 | 152kg | |||||

10kg 페이로드 산업용 로봇 - 컴팩트한 작업 공간을 위한 정밀성, 속도 및 유연성

오늘날의 경쟁적인 제조 환경에서 자동화는 효율성 향상, 비용 절감, 그리고 고품질 생산 기준 유지에 핵심적인 역할을 합니다. 10kg 페이로드 산업용 로봇 전달하기 위해 설계되었습니다 고속, 유연하고 정확한 자동화 ~에 컴팩트한 작업 공간, 다음과 같은 산업에 이상적입니다. 자동차, 전자, 플라스틱 및 금속 제조.

와 함께 6 자유도(DOF), ±0.05mm 반복 위치 정확도, 그리고 CE 및 RoHS 규정 준수 인증, 이것 로봇 팔 보장한다 안정적이고 고성능 작동 다음과 같은 응용 프로그램에서 도장, 용접, 성형, 스탬핑, 단조, 취급, 적재 및 조립.

고급 장비를 갖추고 있습니다 HC 제어 시스템, 이것 산업용 로봇 완벽하게 적합합니다 사출성형기(200T-600T) 및 기타 까다로운 산업 환경. IP54 보호 등급 보장한다 방진 및 방수 성능혹독한 환경에서도 내구성이 뛰어납니다.

10kg 페이로드 산업용 로봇의 주요 특징

1. 고속 및 정밀 성능

10kg의 탑재량 – 중간 규모의 자동화 작업에 이상적입니다.

±0.05mm 반복 위치 정확도 – 보장합니다 초정밀 작업 조립, 용접, 취급 분야에서.

고속 동작 – 최적화됨 빠른 사이클 타임생산 효율성이 향상됩니다.

2. 컴팩트하고 유연한 디자인

6축 로봇팔 – 활성화합니다 다방향 운동 복잡한 작업을 위해.

컴팩트한 설치 공간 – 완벽하게 들어맞습니다 좁은 생산 공간.

넓은 작업 범위 – 재배치 없이 여러 작업 공간을 포괄합니다.

3. 고급 HC 제어 시스템

사용자 친화적인 프로그래밍 – 지원합니다 펜던트 및 오프라인 프로그래밍을 가르치다.

원활한 통합 – 호환 가능 PLC, CNC 및 스마트 팩토리 시스템(Industry 4.0).

실시간 모니터링 및 진단 – 보장합니다 예측 유지 관리 및 최소 가동 중지 시간.

4. 견고하고 신뢰할 수 있는 구조

IP54 보호 – 저항성 먼지, 물 튀김, 산업 잔해.

고강도 알루미늄 및 강철 구성품 – 보장합니다 장기 내구성.

유지 보수가 용이한 디자인 – 운영 비용이 절감됩니다.

5. 안전 및 규정 준수 인증

CE 인증 – 만난다 유럽 안전 및 성능 표준.

RoHS 준수 – 유해 물질이 없어 안심하고 사용 가능 환경 친화적 운영.

6. 다양한 용도에 적용 가능

페인팅 및 코팅 – 전달합니다 일관되고 고품질의 마감.

용접(아크/스팟/MIG/TIG) – 보장합니다 결함이 최소화된 정밀 용접.

몰딩 및 스탬핑 – 자동화합니다 사출성형(200T-600T 기계) 그리고 금속 성형.

자재 취급 및 조립 – 손잡이 고효율 소형~중형 부품.

왜 당사의 10kg 탑재량 산업용 로봇을 선택해야 할까요?

향상된 생산성

사이클 시간을 단축합니다 ~와 함께 고속 작동.

인간의 오류를 최소화합니다 반복적인 작업에서.

처리량이 증가합니다 ~와 함께 24시간 연중무휴 운영 능력.

비용 효율적인 자동화

노동비 절감 수동 작업을 대체함으로써.

재료 낭비를 줄입니다 ~와 함께 초정밀 핸들링.

가동 중지 시간 감소 ~와 함께 안정적이고 유지 보수가 용이한 성능.

미래 지향적 기술

IoT 지원 ~을 위한 원격 모니터링 및 데이터 분석.

협동 로봇(코봇)에 확장 가능.

업그레이드 가능한 소프트웨어 변화하는 산업의 요구에 부응합니다.

산업 응용 분야

1. 자동차 제조

자동차 차체 부품의 정밀 용접.

소형 부품(센서, 기어, 패스너) 취급.

페인팅 및 코팅 응용 분야.

2. 전자제품 및 소비재

PCB 조립 및 테스트.

스마트폰 및 가전제품 생산에서의 소형 부품 취급.

3. 플라스틱 및 사출 성형

200T-600T 사출성형기에서 자동 부품 제거.

플라스틱 부품 분류, 적재 및 포장.

4. 금속 스탬핑 및 단조

프레스에 금속판 적재/하역.

소형 금속 부품의 정밀 단조.

5. 일반 제조 및 조립

픽앤플레이스 작업.

나사 조이기, 접착 및 정밀 조립.

결론: 소형 자동화를 위한 스마트한 선택

우리의 10kg 페이로드 산업용 로봇 제조업체를 위한 완벽한 솔루션입니다. 속도, 정밀도, 유연성 ~에 컴팩트한 작업 공간. 여부 용접, 도장, 성형 또는 조립, 이것 로봇 팔 전달한다 높은 효율성, 신뢰성 및 국제 표준 준수.

이것을 통합함으로써 산업용 로봇 생산 라인에 넣을 수 있습니다 생산성을 높이고 비용을 절감하며 경쟁력을 유지하세요 글로벌 시장에서.

오늘 저희에게 연락하세요 우리의 방법을 배우려면 10kg 페이로드 산업용 로봇 귀사의 제조 공정을 변화시킬 수 있습니다!

SHENCHI ROBOT CO.,LTD는 자동화 솔루션을 갖춘 다양한 산업용 로봇을 제공합니다. 용접, 페인팅, 핸들링, 팔레타이징, 굽힘 및 연마를 포함한 산업용 로봇을 지원합니다. 문의를 환영합니다.

센치 로봇, 더욱 스마트하고 더욱 간단

© Shenchi Company 모든 권리 보유.