- 원링 절강 중국

- [email protected]

- +86 18958695512

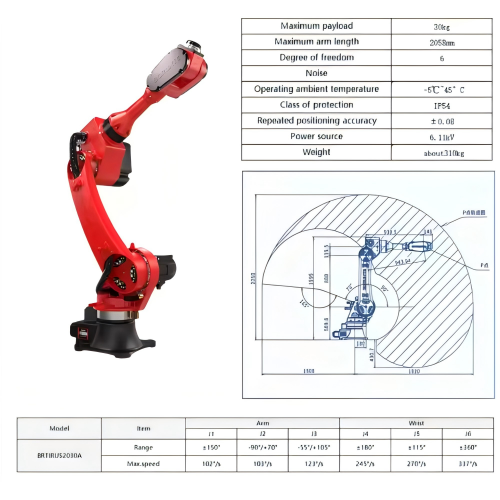

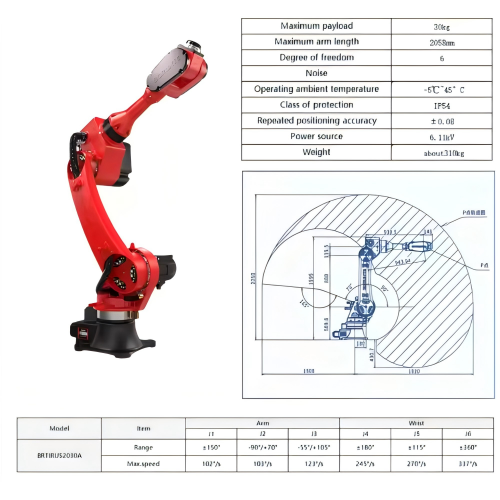

CE 인증을 받은 고정밀 로봇팔 30kg 핫셀

우리의 소개 고정밀 로봇 팔, 뛰어난 성능을 발휘하도록 설계되었습니다. 단조롭고 빈도가 높은 작업 그리고 위험한 환경. 이것 CE 인증 6축 로봇 암 전달한다 탁월한 정확도(±0.02mm 반복성) 그리고 다중 자유도 유연성, 이상적이게 만듭니다

정밀 연마 항공우주/의료 부품

마이크로 어셈블리 전자제품 및 정밀부품

일관된 스프레이 페인팅 완벽한 마무리로

표면 처리 어려운 상황에서

다자유도 운동과 향상된 유연성을 갖춘 고정밀 로봇 솔루션은 정밀 연마, 조립 작업, 분무 도장, 표면 처리 공정 등 다양한 분야에서 탁월한 성능을 발휘합니다. 견고한 설계는 까다로운 산업 환경에서도 안정적인 성능을 보장하는 동시에 탁월한 위치 일관성을 유지합니다.

SC-BR2030

중국

30일

티/티

닝보/상하이 중국

| 도끼 | 6축 | ||||||||||||

| 적재 능력 | 7kg | ||||||||||||

| IP 코드 | IP65 방진 및 방수 | ||||||||||||

| 반복 위치 지정 정확성 | ±0.03mm | ||||||||||||

| 최대 팔 길이 | 700mm | ||||||||||||

| 무게 | 55kg | ||||||||||||

고정밀 로봇: 산업 자동화 우수성을 위한 최고의 솔루션

오늘날 급변하는 제조 환경에서 정밀성과 신뢰성은 더 이상 선택 사항이 아닙니다. 경쟁 우위를 유지하는 데 필수적입니다. 고정밀 로봇 팔 산업 자동화 기술의 정점을 나타내며 특별히 설계되었습니다. 단조롭고 빈도가 높은 반복 작업 ~에 위험하거나 도전적인 환경. 그것으로 다중 자유도 운동 그리고 향상된 유연성, 이것 6축 로봇 암 비교할 수 없는 성능을 제공합니다 정밀 연마, 조립 작업, 분무 도장 및 표면 처리 공정.

인증됨 CE 인증 유럽 시장 규정 준수를 위해 새로운 로봇 팔 결합하다 독일의 엔지니어링 정밀성 ~와 함께 일본 제조 신뢰성전 세계 제조업체에 제공 미래 지향적인 자동화 솔루션 이는 운영 비용을 줄이는 동시에 생산성을 크게 향상시킵니다.

고정밀 로봇 팔, 비교할 수 없는 기술 사양

핵심 성과 지표

-

반복성: ±0.02mm(업계 최고 수준의 정밀도)

-

최대 속도: 3.0m/s(초고처리량)

-

탑재량 용량: 5-15kg(설정 가능)

-

자유도: 6축 완전 관절

-

보호 등급: IP67(방진 및 방수)

고급 모션 제어 시스템

-

고해상도 절대 인코더 (17비트 이상)

-

고급 진동 억제 기술

-

동적 토크 제어 섬세한 작업을 위해

-

실시간 경로 수정 작동 중

스마트 팩토리 통합

-

OPC UA 및 PROFINET 호환성

-

IoT 준비 완료 클라우드 연결성

-

예측 유지 관리 역량

-

디지털 트윈 시뮬레이션 지원

고정밀 로봇 팔 산업별 응용 분야

1. 정밀 연마 및 마무리

-

자동차 부품 마감

-

항공우주 터빈 블레이드 연마

-

의료기기 표면처리

-

가전제품 케이스 마감

사례 연구: 독일 자동차 공급업체의 경우 표면 마감 일관성을 65%로 개선하는 동시에 연마 주기를 40%로 단축했습니다.

2. 고속 조립 작업

-

전자 부품 배치

-

정밀 기계 조립

-

마이크로파트 취급 및 피팅

-

자동 나사 구동 시스템

3. 고급 표면 처리

-

균일한 스프레이 페인팅 적용

-

정밀 코팅 증착

-

레이저 표면 처리

-

플라즈마 코팅 공정

4. 위험 환경 작업

-

폭발성 분위기 취급(ATEX 옵션)

-

고온 주조 응용 분야

-

클린룸 호환 버전

-

부식성 화학 환경

기존 로봇 대비 경쟁 우위

1. 탁월한 정밀 성능

-

30% 더 높은 정확도 비슷한 로봇보다

-

고급 진동 제어 마이크로 수준의 정밀도를 위해

-

열 보상 일관된 성능을 위해

2. 향상된 내구성 기능

-

장갑 케이블 라우팅 연장된 서비스 수명을 위해

-

강화된 고조파 구동 장치 (50,000시간 MTBF)

-

부식 방지 코팅 혹독한 환경을 위해

3. 스마트 제조 준비 완료

-

통합 힘/토크 감지

-

AI 기반 적응형 제어

-

원격 진단 및 모니터링

-

에너지 회수 시스템 (최대 15% 전력 절감)

4. 비용 최적화의 이점

-

50% 소모품 낭비 감소

-

60% 재작업률 감소

-

8~14개월 이내 ROI 대부분의 응용 프로그램에 대해

경쟁 모델과의 비교

고정밀 로봇 팔 사용자 정의 옵션 제공

1. 특수 엔드 이펙터

-

마이크로 그리퍼 섬세한 부품용

-

자기 취급 철 재료용

-

진공 컵 어레이 대형 패널용

-

규정에 맞는 툴링 적응형 어셈블리를 위해

2. 환경별 변형

-

클린룸 등급(ISO 3-5)

-

방폭(ATEX Zone 1)

-

고온(최대 150°C)

-

세척 가능(IP69K)

3. 고급 센서 통합

-

3D 비전 안내 시스템

-

품질 관리를 위한 레이저 스캐닝

-

적응형 핸들링을 위한 힘-토크 감지

-

표면 검사 카메라

구현 및 지원 서비스

1. 전문적인 설치

-

현장 평가 및 계획

-

맞춤형 작업셀 설계

-

안전 시스템 통합

-

생산 라인 시뮬레이션

2. 종합 교육

-

운영자 인증 프로그램

-

유지 보수 기술자 교육

-

프로그래밍 마스터클래스

-

문제 해결 워크숍

3. 지속적인 지원

-

24시간 연중무휴 기술 지원

-

예방 유지 관리 계약

-

예비 부품 재고 관리

-

소프트웨어 업그레이드 서비스

글로벌 제조업체가 고정밀 로봇 팔을 선택하는 이유

우리의 솔루션

1. 입증된 신뢰성

-

MTBF 60,000시간 현장 작업에서

-

전 세계 500개 이상의 설치에서 검증됨

-

군용 등급 구성 요소 선택

2. 미래 지향적 기술

-

새로운 표준으로 펌웨어 업그레이드 가능

-

쉬운 향상을 위한 모듈식 디자인

-

이전 버전과의 호환성 보장

3. 지속 가능한 제조

-

에너지 효율적인 서보 시스템

-

소모성 폐기물 감소

-

재활용 가능한 건축 자재

-

저탄소 발자국 운영

결론: 오늘 생산을 혁신하세요

우리의 고정밀 로봇 제조업체에 제공하는 차세대 산업 자동화를 나타냅니다. 전례 없는 정확성, 신뢰성, 유연성 그들의 운영에서. 당신이 찾고 있는 것이든 정밀 연마의 품질을 향상시키다, 조립 라인의 처리량 증가, 또는 표면 처리의 일관성을 개선합니다, 이것 CE 인증 6축 로봇 암 첫날부터 측정 가능한 성과 개선을 제공합니다.

와 함께 사용자 정의 가능한 구성 특정 애플리케이션 요구 사항을 충족하기 위해 포괄적인 지원 서비스 원활한 통합을 보장하기 위해 당사의 고정밀 로봇 기술은 다음과 같은 기능을 제공합니다. 빠른 ROI ~하는 동안 미래 지향적 자동화 인프라

제조 우수성의 다음 단계로 나아가세요. 오늘 당사의 자동화 전문가에게 연락하여 개인 맞춤형 컨설팅과 데모를 받아보세요.

SHENCHI ROBOT CO.,LTD는 자동화 솔루션을 갖춘 다양한 산업용 로봇을 제공합니다. 용접, 페인팅, 핸들링, 팔레타이징, 굽힘 및 연마를 포함한 산업용 로봇을 지원합니다. 문의를 환영합니다.

센치 로봇, 더욱 스마트하고 더욱 간단

© Shenchi Company 모든 권리 보유.