- 원링 절강 중국

- [email protected]

- +86 18958695512

윙스팬 팔레타이징 로봇 최고의 7kg 산업용 로봇 핫셀

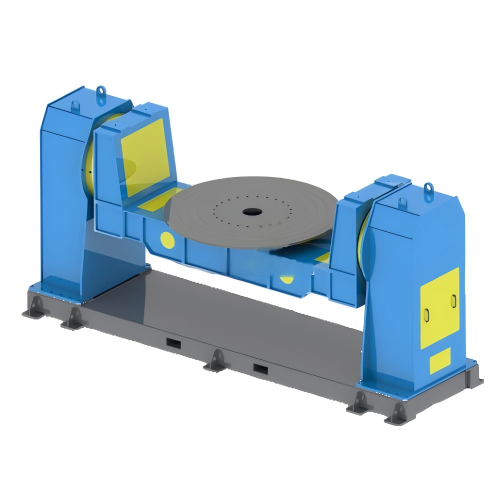

우리는 자랑스럽게 소개합니다 윙스팬 팔레타이징 로봇 – 아 가볍고 공간 절약적이며 고속 자동화 솔루션을 위해 설계되었습니다 조립, 분류, 취급 및 적재/하역 응용 프로그램. 그것과 함께 컴팩트한 구조, 넓은 작업 공간, ±0.02mm 반복성, 이것 7kg 산업용 로봇 전달한다 정밀성, 효율성, 그리고 저렴한 가격, 이상적이게 만듭니다 중소기업 및 대규모 제조업체.

응용 프로그램:

팔레타이징 및 팔레타이징 해제 (상자, 판지 상자, 가방)

기계 관리 (CNC, 사출성형)

조립 및 분류 (전자, 소형 부품)

협업 작업 공간 (근로자 근처에서 안전함)

SC-7-900

중국

30일

티/티

닝보/상하이 중국

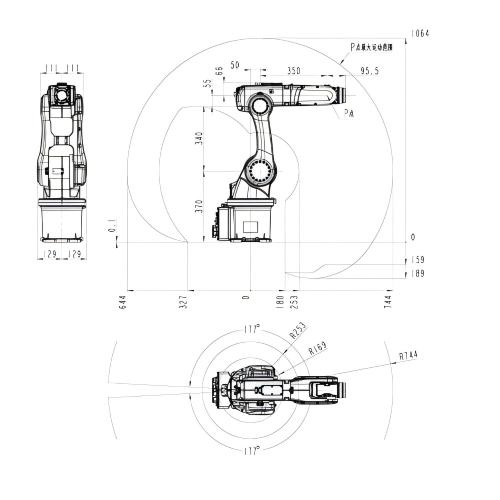

| 자유도 | 6 | ||

| 유효 탑재량 | 7kg | ||

| 날개 길이 | 903.5mm | ||

| 반복성^2 | ±0.02mm |

윙스팬 팔레타이징 로봇 - 컴팩트하고 효율적이며 비용 효율적인 자동화 솔루션

윙스팬 팔레타이징 로봇 이다 소형, 고속 산업용 로봇 특별히 설계된 자동화된 팔레타이징, 분류 및 자재 취급 제조 및 물류 분야에서 가볍지만 내구성이 뛰어난 구조, 넓은 작업 공간 커버리지, 그리고 높은 반복성(±0.02mm), 이상적이게 만듭니다 빠르고 정확한 적재/하역, 조립 및 포장 작업.

우리는 자랑스럽게 소개합니다 윙스팬 팔레타이징 로봇, 아 고성능, 경량, 공간 절약형 자동화 솔루션을 위해 설계되었습니다 조립, 분류, 자재 취급 및 적재/하역 애플리케이션. 그것으로 혁신적인 컴팩트한 구조, 넓은 작업 공간, 빠른 응답 시간, 이것 7kg 산업용 로봇 전달한다 정밀도, 속도, 신뢰성 에서 저렴한 가격따라서 중소 규모의 제조업체에 이상적입니다.

우리의 윙스팬 팔레타이징 로봇 ~하도록 설계되었습니다 노동 비용을 절감하고 생산성을 향상시키며 작업장 안전을 개선합니다.—신뢰받는 500개 이상의 글로벌 고객 다음과 같은 산업에서 물류, 식음료, 제약, 전자제품.

왜 우리의 윙스팬 팔레타이징 로봇을 선택해야 할까요?

1. 컴팩트하고 가벼운 디자인

공간 절약형 발자국 – 바닥 공간이 제한된 시설에 이상적입니다.

가볍지만 내구성이 뛰어납니다 – 알루미늄 합금 및 고강도 복합 소재

쉬운 통합 – 기존 생산 라인에 완벽하게 들어맞습니다.

2. 넓은 작업 공간 및 빠른 속도

확장된 도달 범위(1,200mm 이상) – 표준 로봇보다 더 넓은 작업 영역을 커버합니다.

빠른 사이클 시간(0.5초/픽) – 처리량을 향상시킵니다. 30%+

±0.02mm 반복성 – 정확한 팔레타이징 및 분류를 보장합니다.

3. 다양한 응용 프로그램

팔레타이징 및 팔레타이징 해제 – 상자, 가방, 판지 상자(최대 7kg)

조립 라인 처리 – 소형 부품 분류 및 배치

기계 관리 – CNC, 사출성형, 포장기

협업 작업 공간 – 작업자와 함께 안전한 작업

4. 스마트 제어 및 에너지 효율성

PLC 및 HMI 인터페이스 – 쉬운 프로그래밍 및 작동

IoT 준비 완료 – 실시간 모니터링 및 예측 유지 관리

낮은 전력 소모 – 20%가 더 효율적입니다 경쟁사보다

주요 산업 및 응용 분야

1. 물류 및 창고

자동 상자 적재 전자상거래 이행을 위해

AGV(무인 가이드 차량) 통합

주문 분류 및 컨베이어 벨트 처리

2. 음식 및 음료

병, 캔, 파우치 포장

위생 등급 모델 사용 가능(IP67)

다양한 제품 크기에 대한 빠른 교체

3. 제약 및 전자

정밀 부품 배치

정전 방지 및 클린룸 호환 버전

조립 라인을 위한 소형 부품 분류

4. 일반 제조업

기계 적재/하역

사출 성형 부품 제거

가벼운 물질 전달

경쟁 우위

30% 더 저렴함 – 유럽/일본 브랜드보다 저렴한 비용

더 빠른 ROI – 회수 기간 12개월 미만

플러그 앤 플레이 설치 – 설정 시간 단축

낮은 유지 보수 – 밀봉된 조인트 및 장수명 구성 요소

왜 글로벌 바이어들이 우리를 신뢰할까요?

ISO 9001 및 CE 인증 제조

전 세계적으로 5,000대 이상의 로봇 설치

24시간 연중무휴 기술 지원

모터 및 컨트롤러 3년 보증

사용자 정의 옵션

우리는 다음을 포함한 맞춤형 솔루션을 제공합니다.

특수 엔드 이펙터 (그리퍼, 흡입 컵)

사용자 정의 도달 범위 및 탑재량 구성

비전 가이드 피킹 시스템

브랜딩 및 색상 맞춤 설정

SHENCHI ROBOT CO.,LTD는 자동화 솔루션을 갖춘 다양한 산업용 로봇을 제공합니다. 용접, 페인팅, 핸들링, 팔레타이징, 굽힘 및 연마를 포함한 산업용 로봇을 지원합니다. 문의를 환영합니다.

센치 로봇, 더욱 스마트하고 더욱 간단

© Shenchi Company 모든 권리 보유.