- Wenling zhejiang China

- [email protected]

- +86 18958695512

- Home

- PRODUCTS

- ASSEMBLY LINE

- Pages

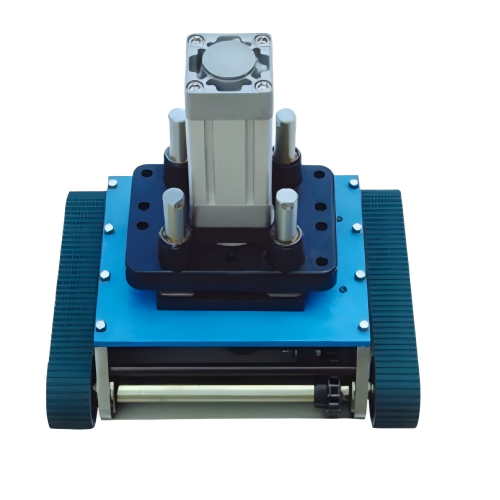

- Lifting and translation machine best automatic assembly line

Lifting and translation machine best automatic assembly line

we produce high-quality Lifting and Translation Machines designed to enhance efficiency in production lines, workshops, and material handling systems. Our machines provide precise lifting, smooth transfer, and automated positioning of workpieces, making them ideal for automotive, electronics, and general manufacturing.

Key Features & Benefits

High Precision (±0.1mm accuracy) – Ensures exact positioning for assembly tasks

Heavy-Duty Construction – Supports 50kg to 2000kg loads with reinforced steel frames

Flexible Integration – Works with conveyor belts, robotic arms, and CNC machines

Smart Control – PLC & HMI programming for automated workflows

Cost-Effective – 30% more affordable than European/US brands

SC-AL-008

CHINA

30DAYS

T/T

NINGBO/SHANGHAI CHINA

Lifting stroke 40mm

motor N-90W 380V 50HZ

High-Performance Lifting and Translation Machines – Optimizing Your Assembly Line Efficiency

As a leading manufacturer of industrial automation equipment, we specialize in Lifting and Translation Machines designed to enhance production line efficiency, reduce manual labor, and improve workflow precision. Our machines are widely used in assembly lines, workshops, and material handling systems, offering seamless lifting, transferring, and positioning of components and products.

Whether you operate an automotive assembly line, electronics manufacturing facility, or general workshop, our Lifting and Translation Machines provide cost-effective, high-quality, and reliable automation solutions. With robust construction, smart control systems, and flexible customization, our machines help businesses increase productivity, reduce operational costs, and maintain consistent quality.

Why Choose Our Lifting and Translation Machines?

1. High Precision & Smooth Operation

Servo-driven lifting mechanism (±0.1mm positioning accuracy)

Smooth translation movement (belt/chain-driven options)

Programmable height adjustment for different workstations

Anti-vibration design for stable load handling

2. Heavy-Duty & Durable Construction

Reinforced steel frame (load capacity: 50kg – 2000kg)

Corrosion-resistant coating for long service life

Low-noise operation (<65 dB) for factory environments

IP54/IP65 protection (dust & water resistance)

3. Smart Automation & Integration

PLC & touchscreen HMI control

Compatible with robotic arms & conveyor systems

Multi-station synchronization for continuous workflow

IoT-ready models for smart factory connectivity

4. Cost-Effective & Fast Delivery

30-50% more affordable than European/US brands

45-60 days lead time (standard models)

Low maintenance & energy-efficient operation

Key Applications

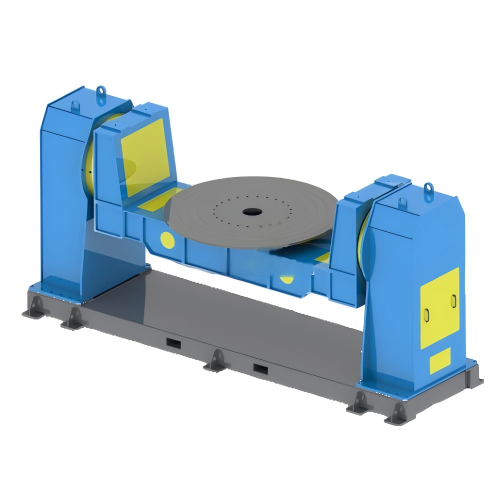

1. Lifting & Assembly Line (Lifting up Assembly Line)

Automotive component assembly (engine, chassis, doors)

Electronics PCB handling & placement

Precision part positioning for welding & fastening

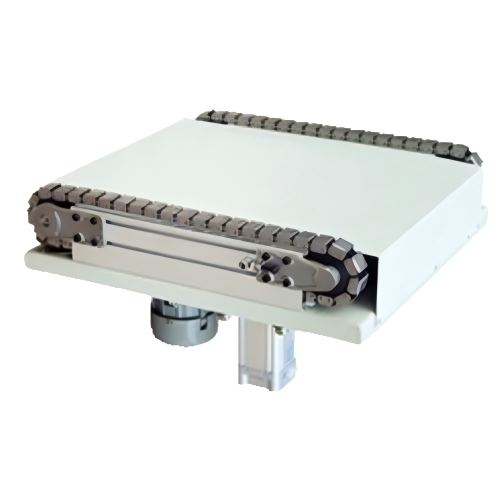

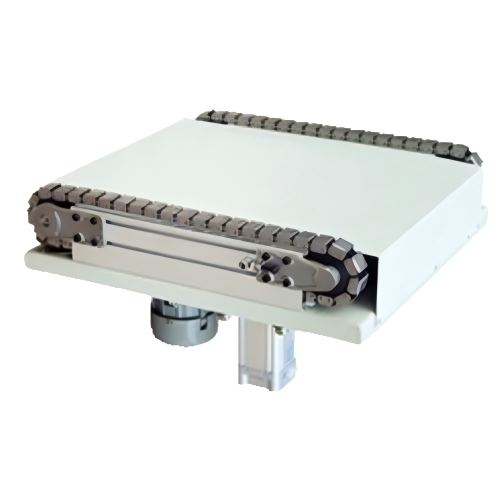

2. Conveyor Belt Integration (Lifting Conveyer Belt Assembly Line)

Workpiece elevation between different conveyor levels

Sorting & transferring goods in logistics centers

Packaging line automation

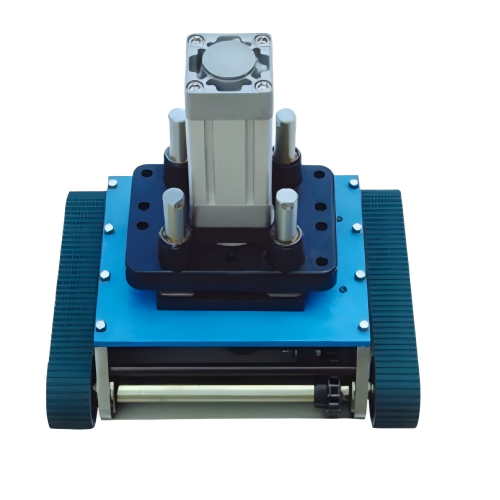

3. Workshop Automation (Workshop Assembly Line)

CNC machine loading/unloading

Heavy part lifting & repositioning

Multi-stage assembly processes

4. Custom Conveyor Systems (Conveyer Belt System For Workshop)

Modular belt/roller conveyors with lifting modules

Incline/decline material transfer systems

Automated guided vehicle (AGV) integration

Competitive Advantages

Higher load capacity than standard lifting systems

Smoother operation with precision guides

Customizable stroke & speed

Easy integration with existing automationWhy Partner With Us?

15+ years of industrial automation expertise

ISO 9001 & CE-certified manufacturing

OEM/ODM services available

Global shipping & after-sales support

SHENCHI ROBOT CO.,LTD provide different industrial robot with automation solutions . we support industrial robots including welding, painting, handling, palletizing, bending and polishing, welcome to contact us.

Shenchi robot ,More smart more simple

© Shenchi Company All right reserved.