- Wenling zhejiang China

- [email protected]

- +86 18958695512

- Home

- PRODUCTS

- INDUSTRIAL ROBOT

- OTHER APPLICATIONS ROBOT

- load handing industrial robot best Assembly Stamping robot

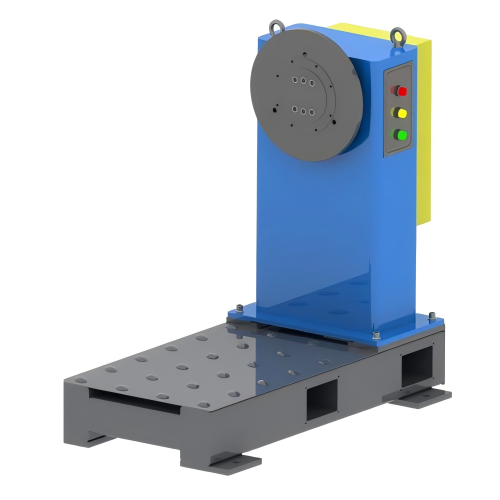

Load handing industrial robot best Assembly Stamping robot

we specialize in load handling industrial robots designed to optimize material transportation, palletizing, and machine tending in modern factories. Our load handling industrial robots combine German engineering precision with competitive Chinese manufacturing costs, delivering high payload capacity (50-2,000kg), fast cycle times, and reliable performance at an affordable price.

Key Features:

Heavy-Duty Construction – Reinforced steel frame with IP67 protection

Precision Handling – ±0.05mm repeatability for accurate placement

High Speed – Up to 2.5m/s for maximum productivity

Smart Control – PLC/HMI interface, IoT-ready

SC-CH2100

CHINA

30DAYS

T/T

NINGBO/SHANGHAI CHINA

High-Performance Load Handling Industrial Robots – Your Trusted Automation Partner

we specialize in load handling industrial robots designed to revolutionize material transportation in modern manufacturing facilities. Our handling robots combine German engineering precision with competitive Chinese manufacturing costs, delivering unmatched payload capacity, operational efficiency, and reliability for factories worldwide.

With over 15 years of industry experience and many successful installations, our load handing industrial robots help manufacturers across automotive, logistics, metalworking, and electronics industries to:

Reduce labor costs by up to 60%

Increase productivity by 30-50%

Improve workplace safety

Optimize floor space utilization

Why Choose Our Load Handling Industrial Robots?

1. Superior Payload & Performance

Heavy-duty models (50kg – 2,000kg capacity)

High-speed operation (up to 2.5m/s)

±0.05mm repeatability for precision handling

Advanced servo control for smooth movement

2. Robust Industrial Construction

Reinforced steel/aluminum frame

IP67 protection (dustproof & waterproof)

50,000-hour MTBF (Mean Time Between Failures)

Overload & collision detection

3. Smart Automation Features

PLC & HMI control integration

Vision-guided picking systems

IoT-ready for Industry 4.0

Multi-robot synchronization

4. Cost-Effective Advantages

30-50% more affordable than European brands

60-day standard delivery

Low energy consumption

Easy maintenance design

Key Applications

1. Automotive Manufacturing

Body panel handling

Engine component transfer

Assembly line feeding

2. Logistics & Warehousing

Palletizing/depalletizing

AGV loading/unloading

Container packing

3. Metal Fabrication

CNC machine tending

Press brake operation

Foundry applications

4. Electronics Production

PCB handling

Display panel transfer

Precision component assembly

Competitive Advantages of load handing industrial robots

Higher payload-to-weight ratio than competitors

Faster acceleration/deceleration

Lower power consumption

Simpler integration with existing systems

Why Global Buyers Trust Us?

ISO 9001 & CE Certified Manufacturing

5-Year Warranty on critical components

24/7 Technical Support

Local Service Partners in 12 countries

Customization Options

We offer:

Special end-effectors (grippers, vacuum cups)

Custom reach configurations

Cleanroom-compatible models

Explosion-proof versions

Success Stories

Case Study 1: European auto parts supplier increased throughput by 45% while reducing handling costs by €350,000 annually.

Case Study 2: Asian electronics manufacturer achieved 99.5% handling accuracy with our vision-guided robots.

Upgrade Your Material Handling Today!

Our load handling industrial robots deliver:

Professional-grade performance

Rapid ROI (typically <12 months)

Future-proof automation Load Handling Industrial Robot is an automated robotic system designed to lift, transport, and position heavy or bulky items in manufacturing, warehousing, and logistics operations. These robots are engineered to replace manual labor in material handling tasks, improving efficiency, precision, and workplace safety.

Who Uses These Robots?

• Automotive Manufacturers (engine/body part handling)

• Warehouses & Logistics Centers (palletizing/sorting)

• Metal & Plastic Fabricators (CNC machine tending)

• Food & Pharmaceutical (hygienic material transfer)Key Features & Capabilities:

High Payload Capacity – Handles weights from 50kg to 2,000kg+

Precision Movement – ±0.05mm to ±0.2mm repeatability for accurate placement

Flexible Automation – Used for palletizing, machine tending, assembly, and more

Smart Integration – Works with PLCs, AGVs, and IoT-enabled systems

SHENCHI ROBOT CO.,LTD provide different industrial robot with automation solutions . we support industrial robots including welding, painting, handling, palletizing, bending and polishing, welcome to contact us.

Shenchi robot ,More smart more simple

© Shenchi Company All right reserved.