- Wenling Zhejiang China

- [email protected]

- +86 18958695512

- Thuis

- PRODUCTEN

- LOPENDE BAND

- Automatische heftafel beste idee ontwerp assemblagelijn

Automatische heftafel beste idee ontwerp assemblagelijn

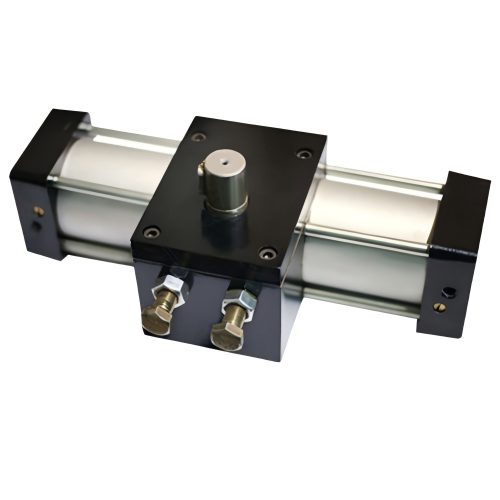

Wij introduceren met trots onze hoogwaardige automatische hefdraaitafel - een innovatief, kosteneffectief oplossing ontworpen om Optimaliseer de materiaalstroom, positioneringsnauwkeurigheid en productie-efficiëntie in productiefaciliteiten over de hele wereld.

Toepassingen

• Automobielassemblage – Positionering van motor/transmissie

• Verpakkingslijnen – Productoriëntatie & overdracht

• Bewerkingscentra – Werkstuk laden/lossen

• Inspectiestations – 360° toegang voor kwaliteitscontrole

Aanpassingsopties:

Speciale laadvermogens/afmetingen

Cleanroom-/explosieveilige varianten

Geïntegreerde visie-/sensorsystemen

SC-AL-63

CHINA

30 DAGEN

T/T

NINGBO/SHANGHAI-CHINA

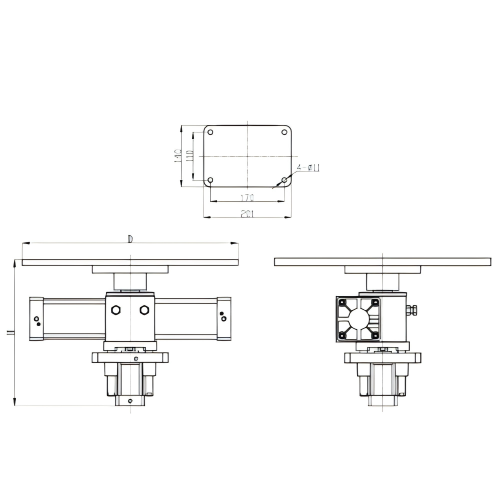

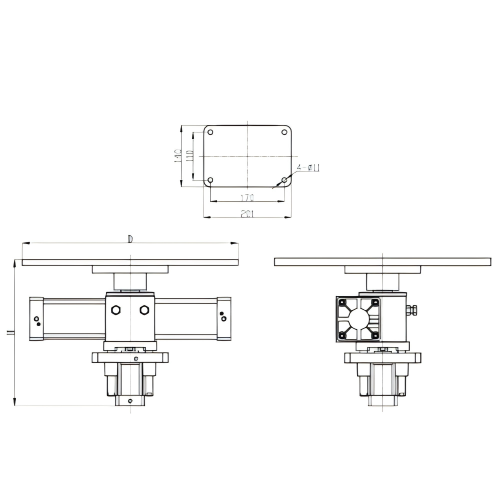

Hefslag: 40 mm, cilinderdiameter 60 mm

tracheale interface 1/8

Automatische hefdraaitafel – Het ultieme slimme positioneringssysteem voor moderne assemblagelijnen

Een Automatische hefdraaitafel is een elektromechanisch positioneringssysteem dat combineert verticale hefbeweging met 360° rotatiebeweging om materiaalverwerking in industriële automatisering te optimaliseren. Deze systemen worden veel gebruikt in assemblagelijnen, verpakkings-, bewerkings- en inspectiestations naar Verbeter ergonomie, precisie en productie-efficiëntie.

Met trots presenteren wij onze hoogwaardige automatische hefdraaitafel - een innovatieve, ruimtebesparende oplossing dat combineert verticaal heffen en 360° rotatie om de materiaalbehandeling in moderne productie te optimaliseren. Ontworpen voor nauwkeurige positionering, ergonomische werkplekken en naadloze integratie, onze draaitafels worden vertrouwd door wereldwijde fabrikanten in de automobiel-, elektronica-, verpakkings- en zware industrie.

Met meer dan 15 jaar technische expertise En Wereldwijd [X.000] units geïnstalleerd, wij leveren:

30% snellere cyclustijden versus handmatige positionering

±0,1 mm verticale / ±0,1° rotatienauwkeurigheid

Draagvermogen van 50 kg tot 2000 kg

30% kosteneffectiever dan Europese alternatieven

Waarom zou u voor onze automatische hefdraaitafel kiezen?

1. Precieze dubbele asbeweging

Soepel verticaal heffen (50-1000mm slag)

360° continue of geïndexeerde rotatie

Servogestuurde besturing voor programmeerbare posities

Anti-vibratie ontwerp voor stabiele lastbehandeling

2. Zware industriële constructie

Versterkt stalen platform met optioneel roestvrijstalen blad

Afgedichte kogelomloopspindel/tandheugelaandrijving (IP54/IP65)

Overbelastingsbeveiliging met noodstop

Levensduur van meer dan 50.000 uur bij normaal gebruik

3. Slimme automatiseringsfuncties

PLC/HMI-besturingsintegratie

IoT-ready voor Industrie 4.0-monitoring

Automatische hoogteaanpassing voor multi-proces werkstations

Barcode-/RFID-trackingcompatibiliteit

4. Kostenbesparende voordelen

40% minder vloeroppervlak dan traditionele overdrachtssystemen

20% energiebesparing met efficiënte servomotoren

Weinig onderhoud (zelf-smerende componenten)

Plug-and-play-installatie

Belangrijkste toepassingen

1. Automobielproductie

Positionering van de motor/transmissie-eenheid

Rotatie van lasarmaturen

Verflijntransport

2. Elektronicaproductie

PCB-inspectiedraaitafels

Precisie-componentassemblage

Integratie van lasermarkeerstations

3. Verpakking en logistiek

Doos-/palletoriëntatie

Rotatie van etiketteerstations

Integratie van sorteersystemen

4. Zware industrie

Behandeling van metaalbewerkingswerkstukken

CNC-machine laden/lossen

Smeedpersvoeding

Concurrentievoordelen

Hogere belasting-tot-formaatverhouding dan concurrenten

Snellere positioneringssnelheid met geoptimaliseerde acceleratie

Stillere werking (<65dB)

CE/ISO gecertificeerde veiligheidsnormen

Aanpassingsopties

Wij bieden:

Speciale platformafmetingen/diameters

Explosieveilige/hygiënische uitvoeringen

Geïntegreerde transportbandsegmenten

Aangepaste besturingsinterfaces

Wereldwijde succesverhalen

Casestudy 1: Duitse autotoeleverancier verkortte de onderdelenoverdrachtstijd met 35% door onze draaitafels te gebruiken bij de batterijassemblage.

Casestudy 2: Japanse elektronicafabrikant behaalde een positioneringsnauwkeurigheid van 99,98% voor de assemblage van microcomponenten.

Waarom vertrouwen fabrikanten ons?

ISO 9001 & CE gecertificeerde productie

Meer dan 15 jaar expertise in bewegingsbesturing

24/7 meertalige technische ondersteuning

3 jaar garantie met garantie op reserveonderdelen

Upgrade vandaag nog uw assemblagelijn!

Ons Automatische hefdraaitafels leveren:

Snellere productiecycli

Ergonomisch werkplekontwerp

Toekomstbestendige automatisering

SHENCHI ROBOT CO.,LTD biedt verschillende industriële robots met automatiseringsoplossingen. Wij ondersteunen industriële robots voor onder meer lassen, verven, hanteren, palletiseren, buigen en polijsten. Neem gerust contact met ons op.

Shenchi-robot, slimmer, eenvoudiger

NEEM CONTACT MET ONS OP

© Shenchi Company Alle rechten voorbehouden.