- Wenling Zhejiang China

- [email protected]

- +86 18958695512

- Thuis

- PRODUCTEN

- INDUSTRIËLE ROBOT

- PALLETISEERROBOT

- Wingspan Palletizing Robot beste 7kg industriële robot hotsell

Wingspan Palletizing Robot beste 7kg industriële robot hotsell

Wij introduceren met trots onze Wingspan Palletiseerrobot - A lichtgewicht, ruimtebesparend en hoge snelheid automatiseringsoplossing ontworpen voor montage, sortering, handling en laden/lossen toepassingen. Met zijn compacte architectuur, grote werkruimte en herhaalbaarheid van ±0,02 mm, dit 7 kg industriële robot levert precisie, efficiëntie en betaalbaarheidwaardoor het ideaal is voor MKB en grootschalige fabrikanten.

Toepassingen:

Palletiseren en depalletiseren (dozen, kartonnen dozen, zakken)

Machinebediening (CNC, spuitgieten)

Assemblage & Sortering (elektronica, kleine onderdelen)

Samenwerkende werkruimten (veilig in de buurt van werknemers)

SC-7-900

CHINA

30 DAGEN

T/T

NINGBO/SHANGHAI-CHINA

| Vrijheidsgraad | 6 | ||

| Lading | 7 kg | ||

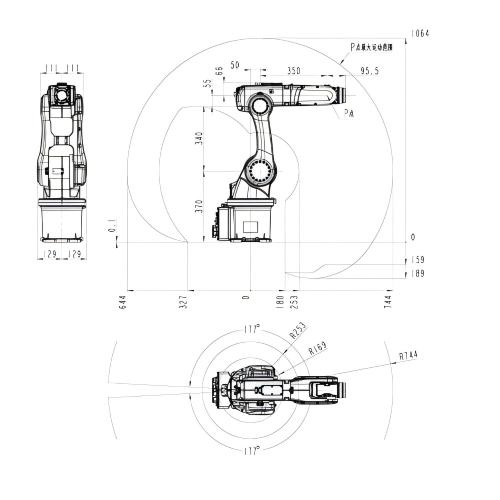

| Spanwijdte | 903,5 mm | ||

| Herhaalbaarheid^2 | ±0,02 mm |

Wingspan Palletizing Robot – Compacte, efficiënte en kosteneffectieve automatiseringsoplossing

Wingspan Palletiseerrobot is een compacte, snelle industriële robot speciaal ontworpen voor geautomatiseerd palletiseren, sorteren en materiaalverwerking in productie en logistiek. Het beschikt over een lichtgewicht maar duurzame structuur, grote werkruimtedekking, En hoge herhaalbaarheid (±0,02 mm)waardoor het ideaal is voor snelle, nauwkeurige laad-/los-, montage- en verpakkingstaken.

Wij introduceren met trots onze Wingspan Palletiseerrobot, A hoge prestaties, lichtgewicht en ruimtebesparend automatiseringsoplossing ontworpen voor assemblage-, sorterings-, materiaalbehandelings- en laad-/lostoepassingen. Met zijn innovatieve compacte architectuur, grote werkruimte en snelle responstijd, dit 7 kg industriële robot levert precisie, snelheid en betrouwbaarheid op een betaalbare prijswaardoor het ideaal is voor kleine tot middelgrote fabrikanten.

Ons Wingspan Palletiseerrobot is ontworpen om arbeidskosten verlagen, productiviteit verhogen en de veiligheid op de werkplek verbeteren—vertrouwd door Meer dan 500 wereldwijde klanten in industrieën zoals logistiek, voeding & dranken, farmaceutica en elektronica.

Waarom zou u voor onze Wingspan-palletiseerrobot kiezen?

1. Compact en lichtgewicht ontwerp

Ruimtebesparende voetafdruk – Ideaal voor faciliteiten met beperkte vloeroppervlakte

Lichtgewicht maar toch duurzaam – Aluminiumlegering en hoogwaardige composietmaterialen

Eenvoudige integratie – Past naadloos in bestaande productielijnen

2. Grote werkruimte en hoge snelheid

Vergroot bereik (1.200 mm+) – Bestrijkt een groter werkgebied dan standaardrobots

Snelle cyclustijden (0,5s/pick) – Verhoogt de doorvoer met 30%+

±0,02 mm herhaalbaarheid – Zorgt voor nauwkeurig palletiseren en sorteren

3. Veelzijdige toepassingen

Palletiseren en depalletiseren – Dozen, zakken, kartonnen dozen (tot 7 kg)

Assemblagelijnafhandeling – Sorteren en plaatsen van kleine onderdelen

Machinebediening – CNC-, spuitgiet- en verpakkingsmachines

Samenwerkende werkruimten – Veilige werking naast werknemers

4. Slimme bediening en energie-efficiëntie

PLC- en HMI-interface – Eenvoudige programmering en bediening

IoT-klaar – Realtime monitoring en voorspellend onderhoud

Laag stroomverbruik – 20% efficiënter dan concurrenten

Belangrijkste industrieën en toepassingen

1. Logistiek en opslag

Geautomatiseerd dozen stapelen voor e-commerce-uitvoering

AGV (Automatisch Geleid Voertuig) integratie

Ordersortering en transportbandafhandeling

2. Eten & Drinken

Verpakking van flessen, blikjes en zakjes

Sanitaire modellen beschikbaar (IP67)

Snelle omschakeling voor verschillende productformaten

3. Farmaceutica en elektronica

Precieze plaatsing van componenten

Antistatische en cleanroom-compatibele versies

Sortering van kleine onderdelen voor assemblagelijnen

4. Algemene productie

Machine laden/lossen

Verwijderen van spuitgietonderdelen

Lichte materiaaloverdracht

Concurrentievoordelen

30% Betaalbaarder – Lagere kosten dan Europese/Japanse merken

Snellere ROI – Terugverdientijd van jonger dan 12 maanden

Plug-and-Play-installatie – Vermindert de insteltijd

Weinig onderhoud – Afgedichte verbindingen en componenten met een lange levensduur

Waarom vertrouwen internationale kopers ons?

ISO 9001 & CE-gecertificeerde productie

Wereldwijd meer dan 5.000 robots geïnstalleerd

24/7 technische ondersteuning

3 jaar garantie op motoren en controllers

Aanpassingsopties

Wij bieden op maat gemaakte oplossingen, waaronder:

Speciale eind-effectoren (grijpers, zuignappen)

Aangepaste bereik- en laadvermogenconfiguraties

Visueel gestuurde picksystemen

Branding en kleuraanpassing

SHENCHI ROBOT CO.,LTD biedt verschillende industriële robots met automatiseringsoplossingen. Wij ondersteunen industriële robots voor onder meer lassen, verven, hanteren, palletiseren, buigen en polijsten. Neem gerust contact met ons op.

Shenchi-robot, slimmer, eenvoudiger

NEEM CONTACT MET ONS OP

© Shenchi Company Alle rechten voorbehouden.