- Wenling Zhejiang Chiny

- [email protected]

- +86 18958695512

- Dom

- PRODUKTY

- ROBOT PRZEMYSŁOWY

- ROBOT MALUJĄCY

- Robot do malowania natryskowego 6-osiowy, nowy, wysokiej jakości robot przemysłowy

Robot do malowania natryskowego 6-osiowy, nowy, wysokiej jakości robot przemysłowy

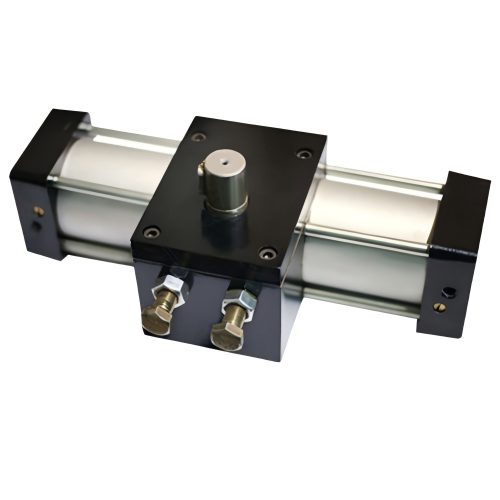

Ulepsz swoje operacje powlekania dzięki naszym zaawansowanym Robot do malowania natryskowego, zaprojektowany dla niezrównana precyzja, trwałość i wydajność w zastosowaniach przemysłowych. Wyposażony w kompaktowa konstrukcja, elastyczność 6-osiowa i ochrona klasy IP65, Ten Malowanie ramienia robota dostarcza odporność na kurz i wodę w trudnych warunkach, przy jednoczesnym zachowaniu Dokładność powtarzania pozycjonowania ±0,5 mm.

Najlepszy do natrysku, ma rozpiętość ramienia 2000 mm i udźwig 13 kg. Ten robot charakteryzuje się kompaktową konstrukcją, wysoką elastycznością i zaawansowaną technologią, co czyni go idealnym do zastosowania w szerokim zakresie branż natryskowych oraz w obsłudze akcesoriów. Wysoki stopień ochrony IP: IP65, pyłoszczelność i wodoodporność. Wysoka dokładność: powtarzalna dokładność pozycjonowania: ±0,5 mm.

SC-BR2013

CHINY

30 DNI

T/T

NINGBO/SZANGHAJ CHINY

Osie | 6 osi | |||||

Możliwość ładowania | 13 kg | |||||

Kod IP | IP65 pyłoszczelność i wodoodporność | |||||

Powtarzalna dokładność pozycjonowania | ±0,5 mm | |||||

Maksymalna rozpiętość ramion | 2000 mm | |||||

Waga | 385 kg | |||||

Robot do malowania natryskowego – precyzja, elastyczność i trwałość w zastosowaniach związanych z powłokami przemysłowymi

W dzisiejszym wymagającym środowisku przemysłowym osiągnięcie spójnego, wysokiej jakości wykończenia powierzchni przy jednoczesnej optymalizacji wydajności produkcji jest ważniejsze niż kiedykolwiek. Robot do malowania natryskowego reprezentuje nową generację zautomatyzowanych rozwiązań do powlekania, łącząc kompaktowa konstrukcja, wysoka elastyczność i najnowocześniejsza technologia zrewolucjonizować procesy lakiernicze w wielu branżach.

Zaprojektowano z Obudowa pyłoszczelna i wodoodporna o stopniu ochrony IP65, Ten Malowanie ramienia robota dostarcza niezrównana niezawodność w trudnych warunkach przemysłowych. Z Dokładność powtarzalnego pozycjonowania ±0,5 mm, nasz Zestaw ramienia robota do natryskiwania zapewnia precyzyjne i równomierne nakładanie powłoki, eliminując błędy ludzkie i znacząco redukując marnotrawstwo materiałów.

Dlaczego warto wybrać naszego robota do malowania natryskowego?

1. Niezrównana precyzja i spójność

Dokładność powtarzalnego pozycjonowania ±0,5 mm do bezbłędnego nakładania powłok

Zaawansowane algorytmy sterowania ruchem zapewnić płynną pracę bez wibracji

Stała grubość filmu we wszystkich elementach obrabianych, co zmniejsza liczbę przeróbek

2. Doskonała ochrona i trwałość

Stopień ochrony IP65 zapewnia pełną ochronę przed pyłem i strumieniami wody

Materiały odporne na korozję wytrzymać trudne warunki malarskie

Uszczelnione zarządzanie kablami zapobiega wnikaniu farby i problemom elektrycznym

3. Wyjątkowa elastyczność i zdolność adaptacji

6-osiowa swoboda ruchu do skomplikowanych geometrii i trudno dostępnych miejsc

System szybkiej wymiany narzędzi do szybkiej konwersji między różnymi powłokami

Kompaktowy rozmiar idealny dla linii produkcyjnych o ograniczonej przestrzeni

4. Zaawansowane funkcje technologiczne

Zintegrowane systemy wizyjne do automatycznego rozpoznawania przedmiotu obrabianego

Programowalne parametry oprysku dla różnych materiałów powłokowych

Monitorowanie w czasie rzeczywistym przepływu farby, ciśnienia i wzoru wachlarza

Zastosowania branżowe

1. Produkcja samochodów

Aplikacja warstwy bazowej/lakieru bezbarwnego do karoserii samochodowych

Aplikacja podkładu na komponentach pojazdów

Operacje poprawkowe w montażu końcowym

2. Przemysł lotniczy i kosmiczny

Powłoka odporna na korozję do podzespołów lotniczych

Aplikacja specjalistycznych farb na materiałach kompozytowych

Powłoka wewnętrzna elementów kabiny

3. Sprzęt przemysłowy

Powłoka ochronna do ciężkich maszyn

Aplikacja powłoki proszkowej na częściach metalowych

Obróbka antykorozyjna do sprzętu outdoorowego

4. Produkty konsumenckie

Wykończenia o wysokim połysku na urządzeniach

Malarstwo dekoracyjne mebli

Powłoki funkcjonalne na obudowach elektronicznych

Przewagi konkurencyjne nad malowaniem ręcznym

Stała jakość: Eliminuje zmienność w technice natrysku spowodowaną przez człowieka

Oszczędności materiałowe:Precyzyjna aplikacja redukuje nadmierne rozpylanie o 20-30%

Bezpieczeństwo pracy:Usuwa pracowników z niebezpiecznych środowisk z oparami

Prędkość produkcji:Działa nieprzerwanie, bez przerw

Śledzenie danych:Cyfrowe zapisy wszystkich parametrów malowania

Integracja inteligentnej fabryki

Nasz Robot do malowania natryskowego jest zaprojektowany z myślą o bezproblemowej integracji z nowoczesnymi inteligentnymi fabrykami:

Łączność IoT do zdalnego monitorowania

Konserwacja predykcyjna możliwości

Kompatybilny z systemami MES/ERP

Energooszczędna praca

Opcje dostosowywania

Rozumiemy, że każde zastosowanie lakiernicze ma unikalne wymagania. Dostępne opcje personalizacji obejmują:

Specjalistyczne efektory końcowe dla różnych technologii natryskowych

Konfiguracje o zwiększonym zasięgu

Wersje przeciwwybuchowe do środowisk łatwopalnych

Niestandardowe systemy dopasowywania kolorów

Wnioski: Przyszłość malarstwa przemysłowego

Nasz Robot do malowania natryskowego stanowi przełomowe rozwiązanie dla producentów, którzy chcą:

Popraw jakość i spójność powłoki

Zmniejsz zużycie materiałów i ilość odpadów

Zwiększ bezpieczeństwo w miejscu pracy

Zwiększenie przepustowości produkcji

Z jego zaawansowana technologia, solidna konstrukcja i precyzyjne działanie, Ten Malowanie ramienia robota jest zaprojektowany, aby dostarczać wyjątkowy zwrot z inwestycji dzięki zwiększonej efektywności i obniżonym kosztom operacyjnym.

Skontaktuj się z naszymi specjalistami ds. automatyki już dziś aby omówić, jak nasze Zestaw ramienia robota do natryskiwania może zoptymalizować Twój proces malowania i zapewnić Ci przewagę konkurencyjną na rynku.

Firma SHENCHI ROBOT CO.,LTD dostarcza różnorodne roboty przemysłowe wraz z rozwiązaniami automatyzacji. Obsługujemy roboty przemysłowe, w tym spawanie, malowanie, przenoszenie, paletyzację, gięcie i polerowanie. Zapraszamy do kontaktu z nami.

Robot Shenchi, mądrzejszy i prostszy

SKONTAKTUJ SIĘ Z NAMI

© Shenchi Company Wszelkie prawa zastrzeżone.