- Wenling zhejiang China

- [email protected]

- +86 18958695512

- Home

- PRODUCTS

- INDUSTRIAL ROBOT

- OTHER APPLICATIONS ROBOT

- Pages

- Polishing robot Grinding Surface remove burrs 30kg Robot

Polishing robot grinding surface remove burrs 30kg robot

Our advanced robotic polishing robot and deburring systems deliver unmatched consistency in surface finishing for metal, plastic, and composite components. Designed for high-mix production environments, these flexible automation solutions eliminate manual labor while improving quality control.

- The design is highly compact, flexible installation with ground or inverse position.

- 6 axis robot with large workspace, high running speed, high repeat positioning accuracy, suitable for spraying, loading and unloading, handling, sorting, assembly and other wide range of applications.

- Repeat positioning accuracy: ±0.05mm

- Armspan: 1668mm

- Payload: 30kg

QJR30-1600

CHINA

30DAYS

T/T

NINGBO/SHANGHAI CHINA

| Model | QJR30-1600 | |

| Axis Number | 6 | |

| Payload | 30kg | |

| Repeat Positioning | ±0.05mm | |

| Max Armspan | 1668mm | |

Advanced Polishing robot Deburring Robots: Precision Finishing Solutions for Global Manufacturers

In modern manufacturing, achieving consistent, high-quality surface finishes is critical for product performance and aesthetics. As a leading industrial robot manufacturer with over 15 years of expertise in automated polishing and deburring solutions, we provide cost-effective, high-performance robots that deliver flawless results while reducing labor costs and production time.

Our polishing robot and deburring robots are designed for industries requiring precision finishing, including automotive, aerospace, medical devices, and energy equipment. Unlike standard robotic systems, we offer complete project-based solutions—from custom tooling and force control to full workcell integration—ensuring seamless adaptation to your specific production needs.

Section 1: Product Overview – Polishing robot & Deburring Robot Series

Key Specifications & Performance Advantages

Payload Capacity: 10-25kg (compatible with various grinding/polishing tools)

Reach: 900-2100mm (customizable for small or large parts)

Repeatability: ±0.03mm for ultra-precise finishing

Force Control: 1-200N adjustable (prevents over-grinding)

Cycle Time: 30-50% faster than manual polishing

Protection Level: IP65 standard (IP67/ATEX optional)

Cost-Saving Value Proposition

40% more affordable than European competitors

5-year mechanical warranty (industry-leading reliability)

30% less material waste with optimized tool paths

Quick ROI (typically <12 months)

Section 2: Manufacturing Excellence & Quality Assurance

2.1 State-of-the-Art Production Facility

Our 60,000m² smart factory features:

Automated robotic calibration stations

Force-control testing rigs (ensuring consistent finishing pressure)

3D simulation software for pre-production validation

Dust & coolant-resistant assembly lines (IP65-rated)

2.2 Rigorous Quality Control

ISO 9001 & ISO 14644-1 certified

72-hour endurance testing for each robot

CE, UL, and SEMI compliance

Full traceability of critical components

Section 3: Complete Project-Based Solutions

3.1 Environment-Adaptive Systems

We engineer polishing robot for challenging conditions:

High-dust environments (foundries, composite workshops) – Enhanced filtration & sealing

Wet polishing applications (coolant/lubricant resistance)

Cleanroom-compatible models (medical & semiconductor industries)

Explosion-proof (ATEX) versions for hazardous zones

3.2 Customized Finishing Solutions

Multi-stage processing (rough grinding → fine polishing)

AI-powered adaptive path planning (compensates for part variances)

Tool-changing systems (automatically switch between abrasives)

Integrated vision inspection (detects defects in real-time

3.3 Turnkey Workcell Integration

We provide complete polishing/deburring cells, including:

Rotary positioners (1-4 axis) for complex geometries

Dust/coolant extraction systems

Automated part loading/unloading

Safety guarding & light curtains

Section 4: Industry Applications

4.1 Automotive

Engine blocks & cylinder heads

Transmission housings

Wheel rims & suspension components

4.2 Aerospace

Turbine blades

Structural aircraft components

Landing gear finishing

4.3 Medical Devices

Surgical instruments

Orthopedic implants

Prosthetics polishing

4.4 Energy & Heavy Industry

Valve bodies & pump housings

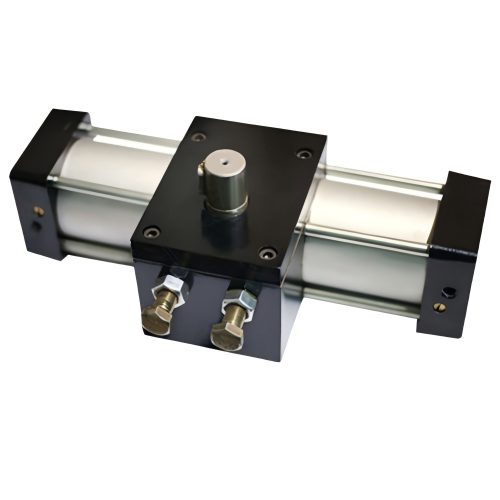

Hydraulic components

Wind turbine parts

Section 5: Why Global Buyers Choose Us

5.1 Unmatched Cost Efficiency

50% lower TCO than competitors

Energy-efficient servo motors (<3.2kWh operation)

Minimal maintenance (sealed joints & dust-proof wiring)

5.2 Engineering Support & Services

Free sample part testing

On-site process optimization

Remote diagnostics & predictive maintenance

5.3 Success Stories

German automotive supplier: 45% faster deburring vs. manual

US aerospace manufacturer: Achieved Ra 0.1µm surface finish

Chinese medical device company: Reduced scrap rate from 8% to 0.5%

Conclusion: Your Trusted Polishing Automation Partner

We don’t just sell robots—we deliver complete, production-ready finishing solutions tailored to your requirements.

Special Offer for New Customers:

Free application assessment

Discounted tooling package

Extended service contract options

SHENCHI ROBOT CO.,LTD provide different industrial robot with automation solutions . we support industrial robots including welding, painting, handling, palletizing, bending and polishing, welcome to contact us.

Shenchi robot ,More smart more simple

© Shenchi Company All right reserved.