- Wenlingzhejiang China

- [email protected]

- +86 18958695512

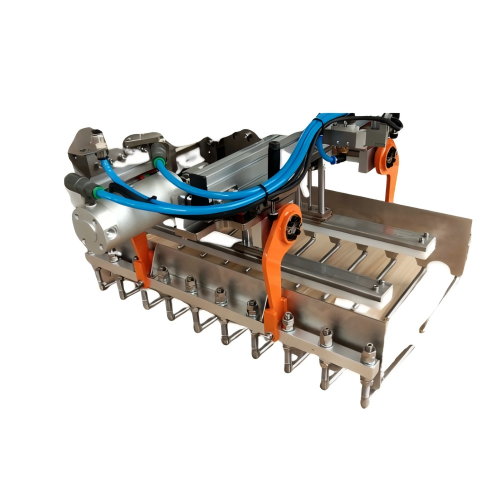

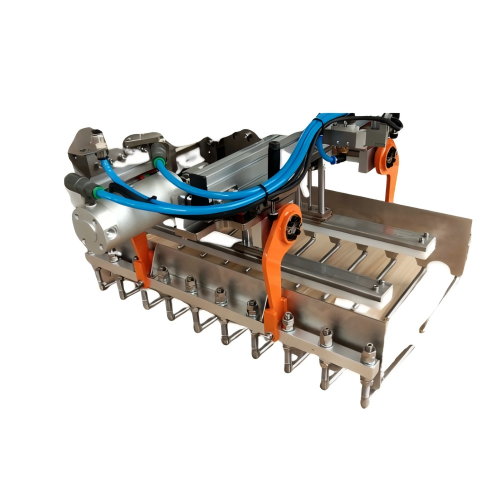

Efetor de extremidade de braço robótico, melhor ferramenta personalizada, efetor de extremidade

nós nos especializamos em pinças de alta qualidade e econômicas para paletização, coleta e colocação, classificação e movimentação de materiais aplicações. Nossas Efetores finais de robôs estão disponíveis em modelos pneumáticos e elétricos, oferecendo precisão, durabilidade e flexibilidade para robôs industriais.

Aplicações:

• Paletização e Despaletização

• Manutenção de máquinas

• Embalagem e classificação

• Automação de linha de montagem

O efetor final pode ser usado em paletização, coleta e colocação, classificação, etc. Temos efetores finais pneumáticos e elétricos, podemos personalizar efetores específicos de acordo com suas necessidades. Efetor final de braço robótico padrão para aplicação comum, Efetor final de braço robótico macio para produtos macios

SC-JJ

CHINA

30 DIAS

T/T

NINGBO/XANGAI CHINA

Efetores de braço robótico profissional - Soluções de automação personalizadas para aplicações industriais

nós nos especializamos em Efetores de extremidade de braço robótico projetado para otimizar o desempenho em paletização, coleta e colocação, classificação e movimentação de materiais aplicações. Nossas Efetores finais de robôs combinar Precisão da engenharia alemã com custos de fabricação chineses competitivos, entregando durabilidade, flexibilidade e custo-benefício incomparáveis para fábricas no mundo todo.

Com mais de [X] anos de experiência na indústria e [X,XXX] unidades instaladas globalmente, nos tornamos um parceiro confiável para fabricantes que buscam melhorar a automação robótica, melhorar a produtividade e reduzir os custos operacionais. Se você precisa pinças padrão, ferramentas robóticas macias ou soluções totalmente personalizadas, nosso Ferramentas personalizadas para efetores finais produtos fornecem confiável e de alto desempenho funcionalidade adaptada às suas necessidades específicas.

Por que escolher nossos efetores de braço robótico?

1. Tecnologia de aderência superior

Múltiplas opções de atuação – Modelos pneumáticos, elétricos e servoelétricos

Força de preensão adaptativa – Ajustável de 5N a 5000N

Repetibilidade de ±0,05 mm – Para manuseio de precisão

Mecanismo de troca rápida – Troca de ferramentas <30 segundos

2. Construção Industrial Robusta

Alumínio de nível aeronáutico corpo com reforço de aço

Proteção IP67 (à prova de poeira e água)

Rolamentos autolubrificantes para operação sem manutenção

MTBF de 50.000 horas (Tempo médio entre falhas)

3. Capacidades de personalização inteligente

Projetos de mandíbulas especializadas – Configurações paralelas, angulares e de 3 dedos

Opções de Robótica Suave – Para produtos delicados (alimentos, eletrônicos)

Sensores Integrados – Feedback de força, detecção de objetos

Revestimentos específicos da indústria – Antiestático, compatível com FDA, alta temperatura

4. Fabricação com boa relação custo-benefício

30-50% menor custo do que marcas europeias/japonesas

Prazo de entrega padrão de 15 dias para modelos de estoque

Garantia de 1 ano com suporte vitalício

Principais aplicações

1. Paletização e movimentação de materiais

Empilhamento de caixas/sacos em centros logísticos

Máquina de atendimento para operações CNC/prensa

Transferência de peças pesadas em fábricas automotivas

2. Alimentos e Farmacêuticos

Manuseio suave de alimentos embalados

Pinças assépticas para ambientes de salas limpas

Aderência compatível para formas irregulares

3. Fabricação de eletrônicos

Ferramentas à prova de ESD para manuseio de PCB

Micro-pinças para componentes pequenos

Colheita guiada por visão sistemas

4. Indústrias Especializadas

Forjamento/ferramentas – Variantes de alta temperatura

Agricultura – Separação/embalagem de produtos

Aeroespacial – Manuseio de materiais compósitos

Vantagens competitivas

Alcance mais amplo – Mais de 50 modelos padrão contra 20-30 dos concorrentes

Entrega mais rápida – 50% mais rápido que a média da indústria

Melhor ROI – Retorno do investimento em <6 meses, normalmente

Suporte global – Centros de serviço em 15 países

Processo de personalização

Análise de Requisitos – Nossos engenheiros analisam suas necessidades

Modelagem 3D – Desenvolvimento de protótipos virtuais

Teste e Validação – Verificações de desempenho no mundo real

Produção e Entrega – Até 30 dias para ferramentas personalizadas

Por que os fabricantes globais confiam em nós

Produção certificada ISO 9001 e CE

Usado por fabricantes da Fortune 500

Suporte técnico 24 horas por dia, 7 dias por semana

Arquivo de Design de 5 anos (reordenações fáceis)

Atualize sua automação hoje mesmo!

Nosso Braço robótico com garra soluções ajudam os fabricantes a:

Aumentar a produtividade por 30-50%

Reduzir custos de mão de obra por 60-80%

Melhore a consistência da qualidade

Melhorar a segurança no local de trabalho

A SHENCHI ROBOT CO.,LTD fornece diferentes robôs industriais com soluções de automação. Oferecemos suporte a robôs industriais, incluindo soldagem, pintura, manuseio, paletização, dobra e polimento. Entre em contato conosco.

Robô Shenchi, mais inteligente e mais simples

© Shenchi Company Todos os direitos reservados.