- Wenling zhejiang China

- [email protected]

- +86 18958695512

- Home

- PRODUCTS

- ASSEMBLY LINE

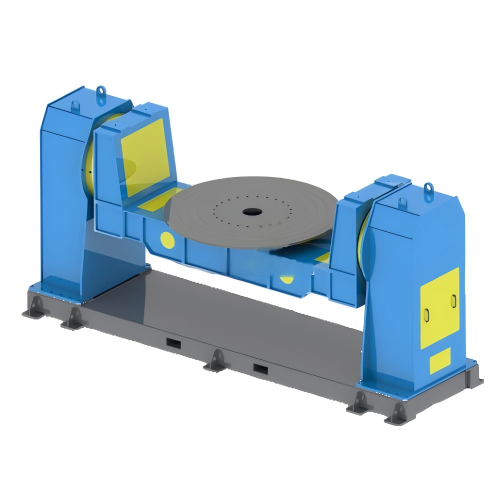

- Rotary Cylinder best Torque Rotary Cylinder in assembly line

Rotary Cylinder High Torque Rotary Cylinder in assembly line

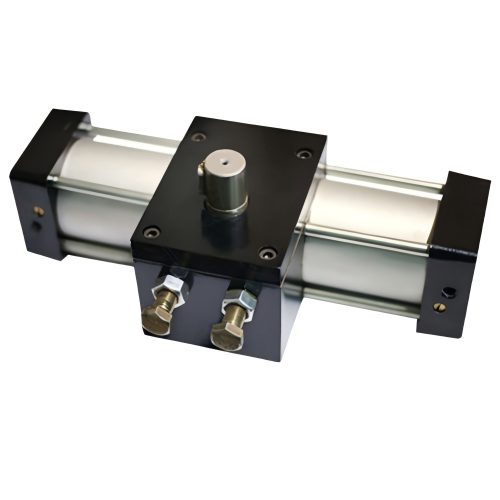

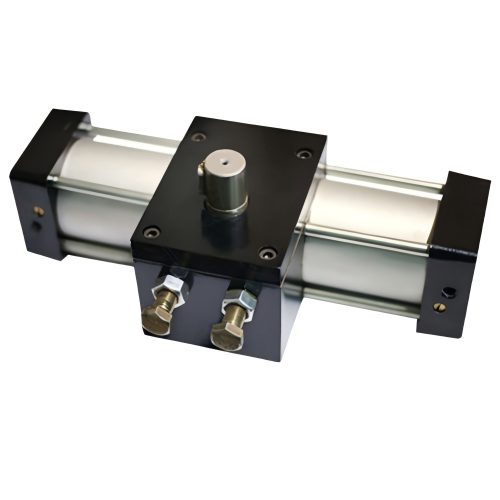

Rotary Cylinder (also called a Rotary Actuator) is a pneumatic or hydraulic device that converts fluid pressure energy into controlled rotational motion. These compact yet powerful components are essential for automated indexing, positioning, and part transfer in modern assembly lines and industrial machinery.

we specialize in Rotary Cylinders that deliver exceptional precision, durability and value for automated production systems. Our cylinders are trusted by 5,000+ manufacturers worldwide for their reliable performance and competitive pricing.

• Automated assembly positioning

• Packaging machine indexing

• Automotive welding fixtures

• Electronics component handling

Hardened steel gears for extended lifespan,Smooth rotation with minimal vibration,Compact designs for space-saving installation,50,000+ hour service life

SC-AL041

CHINA

30DAYS

T/T

NINGBO/SHANGHAI CHINA

High-Performance Rotary Cylinders – Your Trusted Automation Solution

we specialize in high-quality Rotary Cylinders designed to optimize indexing, positioning, and material transfer in automated production systems. Our Rotary Cylinders combine German engineering precision with competitive Chinese manufacturing costs, delivering unmatched durability, accuracy, and value for factories worldwide.

With over [X] years of industry experience and [X,000] successful installations, our cylinders help manufacturers across automotive, electronics, packaging, and general manufacturing industries to:

Increase production speed by 30-50%

Improve positioning accuracy to ±0.01°

Reduce maintenance costs with long-lasting components

Simplify automation integration

Why Choose Our Rotary Cylinders?

1. Superior Engineering & Performance

✔ Precision indexing (±0.01° repeatability)

✔ High torque output (50-5000Nm models available)

✔ Smooth rotation with minimal vibration

✔ Multiple stop positions (2-24 stations)

2. Robust Industrial Construction

Hardened steel gears for extended lifespan

Sealed bearing system (IP65 protection standard)

Corrosion-resistant coatings and materials

50,000+ hour service life under normal operation

3. Smart Customization Options

Compact designs for space-constrained applications

Special mounting configurations

Custom angular increments (15°, 30°, 45°, 90° etc.)

Integrated sensors for position feedback

4. Cost-Effective Advantages

30-40% more affordable than European/Japanese brands

45-day standard lead time

Low maintenance requirements

1-year warranty with extended options available

Key Applications

1. Automated Assembly Lines

Precision component positioning

Indexing between workstations

Part orientation for robotic access

2. Packaging Machinery

Bottle/can indexing for filling

Label application positioning

Case packing orientation

3. Automotive Manufacturing

Engine component assembly

Welding fixture rotation

Paint line conveyance

4. Electronics Production

PCB board handling

Component insertion

Testing station rotation

Competitive Advantages

✔ Higher torque-to-size ratio than competitors

✔ Smoother operation with advanced damping

✔ Easier installation with standardized mounts

✔ Better ROI (typical payback <6 months)

Why Global Manufacturers Trust Us?

ISO 9001 certified production

CE compliant designs

Used by Fortune 500 manufacturers

24/7 technical support

Global spare parts network

Customization Services

We offer:

Special shaft configurations

Explosion-proof versions

High-temperature models (up to 150°C)

Custom branding options

Success Stories

Case Study 1: Automotive supplier reduced indexing time by 40% while improving positioning accuracy.

Case Study 2: Electronics manufacturer achieved 99.9% uptime with our rotary cylinders in PCB assembly.

Upgrade Your Production Today!

Our Rotary Cylinders deliver:

Professional-grade performance

Reliable, maintenance-free operation

Cost-effective automation

Key Features & Working Principle

Rotational Movement

Provides 90° to 360° angular rotation (adjustable)

Delivers high torque output (typically 50Nm–5000Nm)

Precision Engineering

±0.01° to ±0.1° repeatability for accurate positioning

Multiple stop positions (2–24 stations for indexing)

Durable Construction

Hardened steel gears and shafts

IP65/IP67 protection against dust/water

Sealed bearings for 50,000+ hour lifespan

Actuation Options

Pneumatic (most common, for light-mid duty)

Hydraulic (for high-torque applications)

Electric (servo-controlled models)

SHENCHI ROBOT CO.,LTD provide different industrial robot with automation solutions . we support industrial robots including welding, painting, handling, palletizing, bending and polishing, welcome to contact us.

Shenchi robot ,More smart more simple

© Shenchi Company All right reserved.