- Wenling Zhejiang Čína

- [email protected]

- +86 18958695512

- Domov

- PRODUKTY

- PRIEMYSELNÝ ROBOT

- ĎALŠIE APLIKÁCIE ROBOT

- Cobotové robotické rameno najvyššej kvality, horúci predaj, vysoko presný robot

Cobotové robotické rameno najvyššej kvality, horúci predaj, vysoko presný robot

Naše Rameno robotického robota Cobot je navrhnutý pre bezproblémové spolupráca človek-stroj, kombinácia vysoká presnosť, bezpečnosť a flexibilita v priemyselnej automatizácii. S nosnosť 5 kg a dosah 930 mm, toto Manipulačné robotické rameno je perfektný pre výrobné linky s vysokou hustotou, ponuka detekcia kolízií, reprodukcia trasy a rýchla reakcia pre rôzne aplikácie.

● Štruktúra servomotora s reduktorom RV a harmonickým reduktorom, ktorá má malý objem, veľký pracovný rozsah, vysokú rýchlosť a

vysoká presnosť a možno ju integrovať s otočným stolom, reťazovým systémom posuvného dopravníka a ďalším pomocným zariadením.

● Vreckový počítač

Dialógový operátor riadiaceho systému je jednoduchý a ľahko sa učí, čo je veľmi vhodné pre výrobu.

● Telo robota má čiastočné vnútorné zapojenie, ktoré je bezpečné a šetrné k životnému prostrediu

SC-BR0805

ČÍNA

30 DNÍ

DPH

NINGBO/ŠANGHAJ ČÍNA

Sekery | 6 osí | |||||

Nakladacia schopnosť | 5 kg | |||||

IP kód | IP50 | |||||

Opakovaná presnosť polohovania | ±0,2 mm | |||||

Maximálny rozpätie paží | 940 mm | |||||

Hmotnosť | 28 kg | |||||

Robotické rameno Cobot: Revolúcia v spolupráci človeka a robota v modernej výrobe

V dnešnom rýchlo sa rozvíjajúcom priemyselnom prostredí je dopyt po bezpečné, flexibilné a inteligentné automatizačné riešenia nikdy nebola lepšia. Naša Rameno robotického robota Cobot predstavuje špičku technológia kolaboratívnej robotiky, navrhnutý tak, aby bezproblémovo fungoval po boku ľudských operátorov a zároveň poskytoval bezkonkurenčná presnosť, účinnosť a spoľahlivosťS nosnosť 5 kg a dosah 930 mm, toto Vysoko presné kobotové robotické rameno je navrhnutý tak, aby vynikal v flexibilné výrobné linky s vysokou hustotouvďaka čomu je ideálny pre balenie výrobkov, vstrekovanie plastov, nakladanie/vykladanie, montáž a iné presné operácie.

Certifikované s Ochrana proti prachu IP50 a predstavujú pokročilá detekcia kolízií a možnosti reprodukcie stopy, náš Manipulačné robotické rameno stanovuje nové štandardy pre spolupráca človek-stroj v priemyselnom prostredí. Či už chcete zvýšiť produktivitu, zlepšiť bezpečnosť na pracovisku alebo optimalizovať flexibilitu výroby, toto Kolaboratívny robot prináša merateľné výsledky už od prvého dňa.

Kľúčové vlastnosti a technologické výhody

1. Bezpečná spolupráca človeka a robota

Vstavaná detekcia kolízií s technológiou obmedzenia sily

Funkcia okamžitého zastavenia (doba odozvy <10 ms) pri kontakte

Nie sú potrebné žiadne bezpečnostné klietky (pri použití v rámci špecifikácií)

certifikované CE pre štandardy kolaboratívnej prevádzky

2. Vysoko presný výkon

Presnosť opakovaného polohovania ±0,03 mm

Pokročilý systém riadenia servopohonov pre plynulý pohyb

Technológia potlačenia vibrácií pre jemné operácie

Korekcia dráhy v reálnom čase počas prevádzky

3. Inteligentné prevádzkové funkcie

Funkcia reprodukcie stopy pre jednoduché programovanie

Adaptívne riadenie s využitím umelej inteligencie pre variabilné úlohy

Intuitívne rozhranie ovládacieho panela (farebná dotyková obrazovka)

Kompatibilita hlasových príkazov (voliteľné)

4. Flexibilný a ľahký dizajn

Celková hmotnosť <30 kg pre jednoduché premiestnenie

Systém rýchlej výmeny nástrojov (menej ako 1 minúta)

Možnosť otáčania o 360° v stiesnených priestoroch

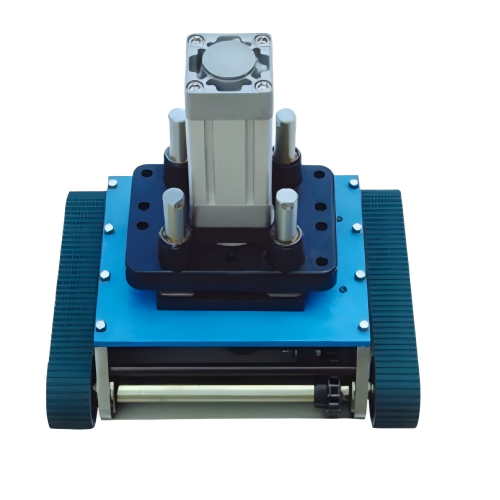

Možnosť mobilného košíka pre flexibilné polohovanie

5. Ekonomické a udržateľné

50% nižšia spotreba energie vs. tradičné roboty

Bezúdržbová prevádzka viac ako 20 000 hodín

Návratnosť investícií dosiahnuteľná za 8 – 12 mesiacov

Modulárny dizajn pre jednoduché vylepšenia

Priemyselné aplikácie

1. Presné montážne operácie

Umiestnenie elektronických súčiastok

Montáž mikrosúčiastok

Aplikácie skrutkovania

Jemné prispôsobenie produktu

2. Balenie a logistika

Balenie a paletizácia v krabiciach

Triedenie a označovanie produktov

Synchronizácia dopravníka

Systémy na vybavovanie objednávok

3. Automatizácia vstrekovania plastov

Odstraňovanie dielov zo strojov 30T-500T

Označovanie vo forme

Oddelenie vtokových kanálov

Kontrola kvality

4. Obsluha strojov

CNC nakladanie/vykladanie

Obsluha ohraňovacieho lisu

Podávanie raziaceho stroja

Správa 3D tlačiarne

5. Kontrola kvality

Systémy vizuálnej kontroly

Laserové meranie

Detekcia povrchových chýb

Overenie rozmerov

Konkurenčné výhody oproti tradičným robotom

1. Porovnanie bezpečnostných ukazovateľov

2. Ekonomické výhody

60% nižšie náklady na inštaláciu (bezpečnostné klietky nie sú potrebné)

Rýchlejšie nasadenie 40% čas

Úspora miesta 30% v porovnaní s tradičnými bunkami

Úspora energie 50% v typickej prevádzke

3. Zvýšenie produktivity

3x rýchlejšia zmena medzi úlohami

Prevádzka 24 hodín denne, 7 dní v týždni schopnosť

Takmer nulová miera chybovosti v presných aplikáciách

Redukcia 50% pri poškodení produktu

Možnosti prispôsobenia

1. Riešenia koncových efektorov

Vákuové chápadlá pre rovné povrchy

Elektrické chápadlá pre presné držanie

Magnetické manipulátory pre železné materiály

Špecializované nástroje pre jedinečné aplikácie

2. Integrácia inteligentnej továrne

Balíky pripojenia IoT

Cloudové monitorovanie

Prediktívne systémy údržby

Simulácia digitálnych dvojčiat

3. Varianty špecifické pre dané prostredie

Verzie s ochranou proti elektrostatickej elektřine (ESD) pre elektroniku

Modely vhodné do potravín s certifikáciou NSF

Možnosti pre vysoké teploty pre zlievarne

Kompatibilné s čistými priestormi návrhy

Implementácia a podpora

1. Profesionálne služby

Posúdenie rizika na mieste

Aplikačné inžinierstvo

Návrh rozloženia buniek

Overenie bezpečnosti

2. Komplexné školenie

Certifikácia operátora

Programovacie workshopy

Školenie údržby

Sprievodcovia riešením problémov

3. Neustála podpora

Technická pomoc 24 hodín denne, 7 dní v týždni

Diaľková diagnostika

Plány preventívnej údržby

Aktualizácie softvéru

Prečo si globálni výrobcovia vyberajú nášho kobota

1. Osvedčená spoľahlivosť

MTBF > 60 000 hodín v terénnych operáciách

Overené vo viac ako 1 000 inštaláciách

Výber komponentov vojenskej triedy

2. Technológia pripravená na budúcnosť

Možnosť aktualizácie firmvéru

Platforma pripravená na umelú inteligenciu

Plán neustáleho zlepšovania

3. Udržateľná výroba

Energeticky úsporný dizajn

Znížený odpad materiálu

Recyklovateľná konštrukcia

Záver: Budúcnosť kolaboratívnej automatizácie

Naše Rameno robotického robota Cobot predstavuje transformačný prístup k priemyselnej automatizácii, ktorý kombinuje ľudská obratnosť s robotickou presnosťou vytvoriť inteligentnejšie, bezpečnejšie a efektívnejšie výrobné prostredia. Vďaka svojim bezkonkurenčná flexibilita, presný výkon a bezpečnostné prvky pre spoluprácu, toto Vysoko presné kobotové robotické rameno nanovo definuje možnosti modernej výroby.

Urobte prvý krok k inteligentnejšej automatizácii – kontaktujte našich špecialistov na robotiku ešte dnes a získajte personalizovanú konzultáciu a živú ukážku.

Spoločnosť SHENCHI ROBOT CO., LTD. poskytuje rôzne priemyselné roboty s automatizačnými riešeniami. Podporujeme priemyselné roboty vrátane zvárania, lakovania, manipulácie, paletizácie, ohýbania a leštenia, neváhajte nás kontaktovať.

Shenchi robot, inteligentnejší a jednoduchší

KONTAKTUJTE NÁS

© Spoločnosť Shenchi Všetky práva vyhradené.