- Wenling Zhejiang Kitajska

- [email protected]

- +86 18958695512

- Domov

- IZDELKI

- INDUSTRIJSKI ROBOT

- DRUGE UPORABE ROBOT

- Strani

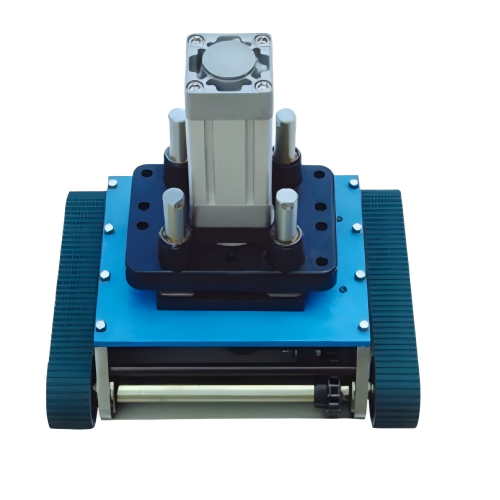

- Robot za poliranje, brušenje površin, odstranjevanje robov, 30 kg robot

Robot za poliranje, brušenje površine, odstranjevanje zarobkov, 30 kg robot

Naša napredna robotska roboti za poliranje in sistemi za odstranjevanje robov Zagotavljajo neprekosljivo doslednost pri površinski obdelavi kovinskih, plastičnih in kompozitnih komponent. Te prilagodljive rešitve za avtomatizacijo, zasnovane za okolja z veliko mešanico proizvodnih materialov, odpravljajo ročno delo in hkrati izboljšujejo nadzor kakovosti.

- Zasnova je zelo kompaktna, namestitev pa je fleksibilna, s talnim ali obrnjenim položajem.

- 6-osni robot z velikim delovnim prostorom, visoko hitrostjo delovanja, visoko natančnostjo ponavljajočega se pozicioniranja, primeren za škropljenje, nakladanje in razkladanje, rokovanje, sortiranje, montažo in druge široke palete aplikacij.

- Natančnost pozicioniranja ponovitve: ±0,05 mm

- Razpon rok: 1668 mm

- Nosilnost: 30 kg

QJR30-1600

KITAJSKA

30 DNI

T/T

NINGBO/ŠANGHAJ KITAJSKA

| Model | QJR30-1600 | |

| Številka osi | 6 | |

| koristni tovor | 30 kg | |

| Ponovi pozicioniranje | ±0,05 mm | |

| Največji razpon rok | 1668 mm | |

Napredni robot za poliranje in odstranjevanje robov: Rešitve za natančno končno obdelavo za globalne proizvajalce

V sodobni proizvodnji je doseganje dosledne, visokokakovostne površinske obdelave je ključnega pomena za delovanje in estetiko izdelka. Kot vodilni industrijski robot proizvajalec z več kot 15 leti izkušenj na področju avtomatizirane rešitve za poliranje in odstranjevanje robov, nudimo stroškovno učinkoviti, visokozmogljivi roboti ki prinašajo brezhibni rezultati ob hkratnem zmanjšanju stroškov dela in časa proizvodnje.

Naše roboti za poliranje in roboti za odstranjevanje robov so zasnovani za panoge, ki zahtevajo natančna končna obdelava, vključno z avtomobilska, vesoljska, medicinska in energetska opremaZa razliko od standardnih robotskih sistemov ponujamo celovite projektne rešitve—od orodja po meri in nadzor sile do popolne integracije delovne celice—zagotavljanje brezhibne prilagoditve vašim specifičnim proizvodnim potrebam.

1. razdelek: Pregled izdelka – serija robotov za poliranje in odstranjevanje robov

Ključne specifikacije in prednosti delovanja

Nosilnost: 10–25 kg (združljivo z različnimi orodji za brušenje/poliranje)

Doseg: 900–2100 mm (prilagodljivo za majhne ali velike dele)

Ponovljivost: ±0,03 mm za ultra natančno končno obdelavo

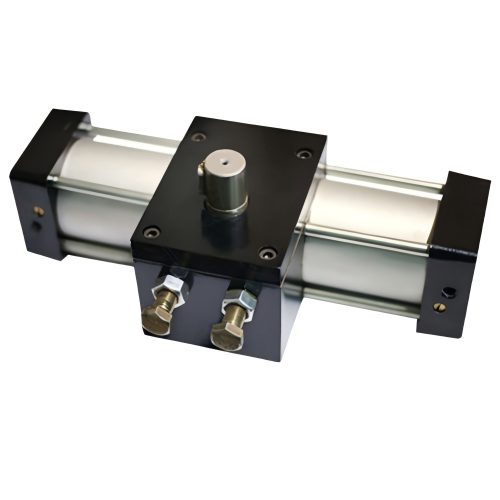

Nadzor sile: 1–200 N nastavljiv (preprečuje prekomerno mletje)

Čas cikla: 30-50% hitrejši kot ročno poliranje

Stopnja zaščite: Standard IP65 (IP67/ATEX opcijsko)

Ponudba za varčevanje z vrednostjo

40% cenovno ugodnejši kot evropski konkurenti

5-letna mehanska garancija (vodilna zanesljivost v panogi)

30% manj odpadnega materiala z optimiziranimi potmi orodja

Hitra donosnost naložbe (običajno <12 mesecev)

Oddelek 2: Odličnost proizvodnje in zagotavljanje kakovosti

2.1 Najsodobnejši proizvodni obrat

Naše 60.000 m² pametne tovarne značilnosti:

Avtomatizirane robotske kalibracijske postaje

Naprave za testiranje nadzora sile (zagotavljanje enakomernega zaključnega pritiska)

Programska oprema za 3D simulacijo za predprodukcijsko validacijo

Montažne linije, odporne na prah in hladilno tekočino (zaščita IP65)

2.2 Strog nadzor kakovosti

Certificirano po ISO 9001 in ISO 14644-1

72-urno testiranje vzdržljivosti za vsakega robota

Skladnost s CE, UL in SEMI

Popolna sledljivost kritičnih komponent

Oddelek 3: Celovite rešitve, ki temeljijo na projektih

3.1 Okolju prilagojeni sistemi

Izdelujemo polirnega robota za zahtevne pogoje:

Okolja z visoko vsebnostjo prahu (livarne, delavnice za kompozitne materiale) – Izboljšana filtracija in tesnjenje

Mokro poliranje (odpornost na hladilno tekočino/mazivo)

Modeli, primerni za čiste prostore (medicinska in polprevodniška industrija)

Eksplozijsko varne (ATEX) različice za nevarna območja

3.2 Prilagojene rešitve za končno obdelavo

Večstopenjska obdelava (grobo brušenje → fino poliranje)

Prilagodljivo načrtovanje poti z umetno inteligenco (kompenzira odstopanja delov)

Sistemi za menjavo orodij (samodejno preklapljanje med abrazivi)

Integrirani vizualni pregled (zazna napake v realnem času

3.3 Integracija delovnih celic na ključ

Nudimo popolne celice za poliranje/razigljevanje, vključno z:

Rotacijski pozicionerji (1-4 osi) za kompleksne geometrije

Sistemi za odsesavanje prahu/hladilne tekočine

Avtomatizirano nakladanje/razkladanje delov

Varnostne zaščite in svetlobne zavese

Oddelek 4: Uporaba v industriji

4.1 Avtomobilska industrija

Bloki motorjev in glave valjev

Ohišja menjalnika

Platišča in komponente vzmetenja

4.2 Letalstvo in vesolje

Lopatice turbin

Strukturne komponente letala

Dokončanje podvozja

4.3 Medicinski pripomočki

Kirurški instrumenti

Ortopedski vsadki

Poliranje proteze

4.4 Energetika in težka industrija

Ohišja ventilov in črpalk

Hidravlične komponente

Deli vetrnih turbin

Oddelek 5: Zakaj nas izberejo globalni kupci

5.1 Neprimerljiva stroškovna učinkovitost

50% nižji skupni stroški lastništva kot konkurenti

Energetsko učinkoviti servo motorji (<3,2 kWh delovanja)

Minimalno vzdrževanje (zatesnjeni spoji in ožičenje, odporno proti prahu)

5.2 Inženirska podpora in storitve

Brezplačno testiranje vzorčnih delov

Optimizacija procesov na kraju samem

Oddaljena diagnostika in prediktivno vzdrževanje

5.3 Zgodbe o uspehu

Nemški dobavitelj avtomobilske opreme: 45% hitrejše odstranjevanje robov v primerjavi z ročnim

Ameriški proizvajalec letalske in vesoljske opreme: Doseženo Površinska obdelava Ra 0,1 µm

Kitajsko podjetje za medicinske pripomočke: Zmanjšana stopnja odpadkov od 8% do 0,5%

Zaključek: Vaš zaupanja vreden partner za avtomatizacijo poliranja

Ne prodajamo samo robotov – dostavljamo celovite rešitve za dodelavo, pripravljene za proizvodnjo prilagojeno vašim zahtevam.

Posebna ponudba za nove stranke:

Brezplačna ocena prijave

Paket orodij s popustom

Možnosti podaljšane pogodbe o storitvah

SHENCHI ROBOT CO., LTD ponuja različne industrijske robote z rešitvami za avtomatizacijo. Podpiramo industrijske robote, vključno z varjenjem, barvanjem, rokovanjem, paletiranjem, upogibanjem in poliranjem, zato nas kontaktirajte.

Shenchi robot, pametnejši in preprostejši

KONTAKTIRAJTE NAS

© Podjetje Shenchi Vse pravice pridržane.