- Wenling zhejiang Kina

- [email protected]

- +86 18958695512

- Hem

- PRODUKTER

- INDUSTRIROBOT

- SVETSROBOT

- Sidor

- 6 kg bågsvetsrobot bästa metallsvetsningsindustrirobot

6 kg bågsvetsrobot bästa metallsvetsningsindustrirobot

Öka din produktionseffektivitet med våra avancerade 6 kg bågsvetsrobot, en högprecisions svetsrobotarm utformad för överlägsen prestanda i bågsvetsning, transporttillämpningar och lasersvetsningOavsett om den är integrerad i en Svetsarbetsstation eller en Lasersvetsningsrobotstation, detta mångsidiga robotsystem levererar felfria svetsar med oöverträffad hastighet och noggrannhet.

Viktiga funktioner och fördelar

6 kg nyttolastkapacitet

Flerprocesssvetsning

Hög repeterbarhet (±0,02 mm)

Smart svetsteknik

Flexibel integration

Tillämpningar inom olika branscher

Bil Tung industri Precisionsteknik

SC-CH1603

KINA

30 DAGAR

T/T

NINGBO/SHANGHAI KINA

6 kg bågsvetsrobot: Framtiden för precisionssvetsautomation

I dagens snabbt föränderliga tillverkningslandskap är precision, effektivitet och flexibilitet inte längre valfria – de är avgörande för att bibehålla konkurrensfördelar. Vår 6 kg bågsvetsrobot representerar toppen av svetsautomationsteknik och erbjuder oöverträffad prestanda i bågsvetsning, transporttillämpningar och lasersvetsintegrationUtformad som en komplett svetsrobotarm lösning, detta system kan sömlöst integreras i både standard Svetsarbetsstationer och avancerad Lasersvetsningsrobotstationer, vilket ger tillverkare oöverträffad mångsidighet.

Denna omfattande guide på 2000 ord kommer att utforska hur vår 6 kg bågsvetsrobot revolutionerar industriella svetsprocesser och beskriver i detalj sina tekniska specifikationer, innovativa funktioner, mångsidiga tillämpningar och den betydande avkastning på investeringen den ger. Oavsett om du arbetar inom fordonstillverkning, tunga maskiner eller precisionselektronik är denna robotsvetslösning konstruerad för att höja din produktionskapacitet till nya höjder.

Tekniska specifikationer och viktiga funktioner

1. Precisionsteknik för felfria svetsar

6 kg nyttolastkapacitet optimerad för hantering av svetsbrännare och manipulation av medelstora arbetsstycken

±0,02 mm repeterbarhet säkerställer konsekventa svetsar av hög kvalitet

Avancerat servostyrningssystem för smidig, vibrationsfri rörelse

IP54-klassat skydd mot damm och vattenstänk för tuffa miljöer

2. Svetsningsmöjligheter för flera processer

MIG/MAG-svetsning med adaptiv spänningsreglering

TIG-svetsning kompatibilitet för precisionsapplikationer

Integrering av lasersvetsning i Lasersvetsningsrobotstation konfigurationer

Plasmasvetsning tillgängliga alternativ

3. Smarta svetstekniker

Sömspårning i realtid med laservisionssystem

Adaptiv fyllningsteknik för perfekt svetssträngsbildning

Automatisk rengöring av brännaren system för att minimera driftstopp för underhåll

Svetsparameterminne för snabba jobbbyten

4. Ergonomisk design och integration

Kompakt fotavtryck sparar värdefull golvyta

6-axlig ledad arm med 1500 mm räckvidd

Snabbmontering av verktyg för olika svetsprocesser

Förintegrerade säkerhetssystem inklusive kollisionsdetektering

Branschspecifika tillämpningar

1. Biltillverkning

Vittkroppssvetsning med perfekt repeterbarhet

Tillverkning av chassikomponenter

Montering av avgassystem

Batterifacksvetsning för elfordon

2. Tunga maskiner och byggutrustning

Svetsning av strukturellt stål

Bom- och armmontering

Tillverkning av skopa och redskap

Ram- och chassikonstruktion

3. Precisionsteknik och elektronik

Medicintekniska komponenter

Strukturelement för flyg- och rymdfart

Svetsning av sensorhus

Mikrosvetsapplikationer i Lasersvetsningsrobotstation läge

4. Allmän metalltillverkning

Tillverkning av möbler i metall på beställning

Arkitektoniskt metallarbete

Rör- och slangsvetsning

Reparation och underhåll av industriell utrustning

Systemintegrationsalternativ

1. Fristående svetsarbetsstation

Komplett plug-and-play Svetsarbetsstation lösning

Inkluderar robot, strömkälla, trådmatarverk och säkerhetshölje

Förprogrammerade svetsrutiner för vanliga tillämpningar

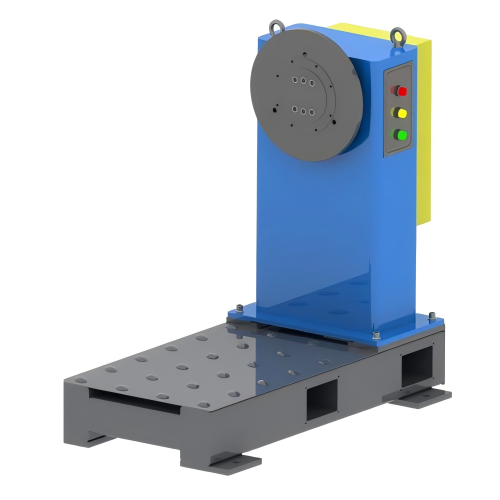

Valfri positionerare för komplexa geometrier

2. Konfiguration av lasersvetsningsrobotstation

Integrering av högprecisionslasersvetsning

Fiberlaserkällor från 1 kW till 6 kW

Automatisk fokusjustering

Visuellt guidat sömspårningssystem

3. Flexibel tillverkningscell

Multirobotkoordinerad svetsning

Integrerad materialhantering

Automatiserad lastning/lossning av delar

Smart fabriksanslutning (redo för Industri 4.0)

Konkurrensfördelar

1. Oöverträffad svetskvalitet

Jämn penetration och pärlliknande utseende

Praktiskt taget inget stänk med avancerad vågformskontroll

Minskat behov av rengöring efter svetsning

Röntgenkvalitetssvetsar i kritiska applikationer

2. Produktivitetsförbättringar

30-50% snabbare än manuell svetsning

Kontinuerlig drift dygnet runt

Samtidiga svets- och positioneringsrörelser

Snabbt byte mellan jobb

3. Kostnadsbesparingar

Upp till 60% reduktion i arbetskraftskostnader

30% mindre förbrukning av fyllnadsmaterial

Minimalt omarbete och skrot

Lägre energiförbrukning än konventionella system

4. Framtidssäker teknik

Programvaran kan uppgraderas för nya svetsprocesser

Modulär design för enkel expansion

IoT-anslutning för prediktivt underhåll

Kompatibilitet med nya Industri 4.0-standarder

Teknisk support och service

Vi förstår att införandet av ny automationsteknik kräver omfattande support. Vårt globala servicenätverk erbjuder:

Installation på plats och driftsättning

Operatörsutbildning program

Förebyggande underhåll kontrakt

Fjärrdiagnostik och felsökning

Reservdelar tillgänglighetsgaranti

Fallstudier och framgångshistorier

Fallstudie 1: Leverantör av högsta kvalitet inom fordonsindustrin

En stor tillverkare av bilkomponenter implementerade vår 6 kg bågsvetsrobot i deras produktionslinje för hjälpramar, vilket uppnår:

45% ökning i daglig produktion

Minskning av svetsfelfrekvensen från 5% till 0,2%

Uppnådd avkastning på bara 8 månader

Fallstudie 2: Tillverkare av tung utrustning

Integrering av vår svetsrobotarm in i deras Svetsarbetsstation för grävmaskinsbomproduktion resulterade i:

60%-reduktion vid svetsarbetskostnader

35% minskning i materialavfall

Förbättrad arbetssäkerhet genom att avlägsna personal från farliga svetsområden

Slutsats: Förvandla din svetsverksamhet idag

Vår 6 kg bågsvetsrobot representerar den perfekta balansen mellan precision, kraft och flexibilitet för modern tillverkning. Oavsett om den används fristående Svetsarbetsstation eller som en del av en avancerad Lasersvetsningsrobotstation, detta system ger mätbara förbättringar av kvalitet, produktivitet och lönsamhet.

Med sin förmåga att hantera bågsvetsning, transporttillämpningar och lasersvetsning Med samma kompetens eliminerar denna robotlösning behovet av flera specialiserade maskiner, vilket minskar dina kapitalinvesteringar samtidigt som din produktionskapacitet ökar.

Ta det första steget mot excellens inom svetsautomation – kontakta vårt tekniska team idag för en personlig konsultation och demonstration.

SHENCHI ROBOT CO.,LTD erbjuder olika industrirobotar med automationslösningar. Vi stöder industrirobotar inklusive svetsning, målning, hantering, palletering, bockning och polering, välkommen att kontakta oss.

Shenchi-robot, smartare och enklare

© Shenchi Company Alla rättigheter förbehållna.