- Wenling zhejiang Kina

- [email protected]

- +86 18958695512

- Hem

- PRODUKTER

- POSITIONERINGSSTÄLLE

- Svetslägesställare bästa enaxliga lägesställare 800/1000 kg

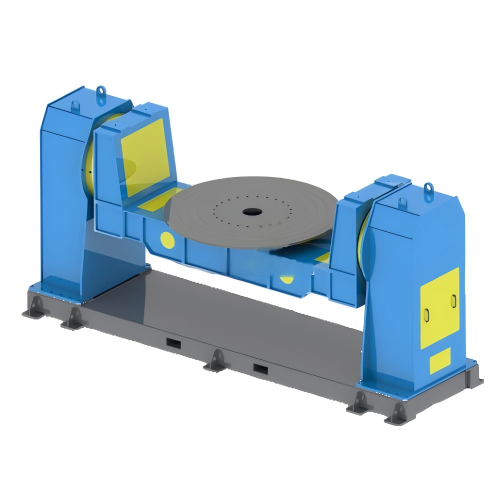

Svetslägesställare bästa enaxliga lägesställare 800/1000 kg

Som specialist inom arbetsstationer för integration av industriella robotsystem, presenterar vi stolt vår 800 kg svetspositionerare – en viktig del av moderna svetsrobotarbetsstationerDenna robusta svetsrobotpositionerare kombinerar precisionsteknik med industriell hållbarhet, speciellt utformad för tunga automationsapplikationer.

Tekniska fördelar:

Precisionsplanetväxellåda säkerställer smidig och vibrationsfri drift

Standard PROFINET/DeviceNet-gränssnitt för enkel robotsynkronisering

Anpassningsbara klämfixturer för olika arbetsstyckesgeometrier

IP54-skyddsklassning för krävande verkstadsmiljöer

SC-PZ-800/1000

KINA

30 DAGAR

T/T

NINGBO/SHANGHAI KINA

| Axelnummer | 6 |

|---|---|

| Nyttolast | 800/1000 kg |

| Upprepa positionering | ±0,15 mm |

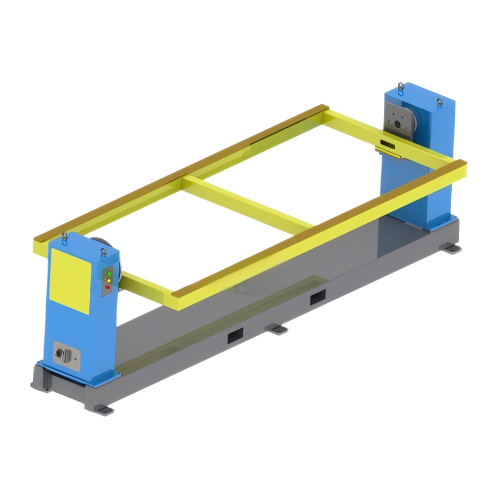

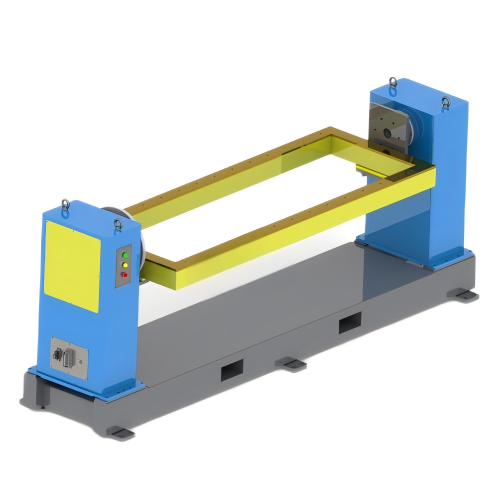

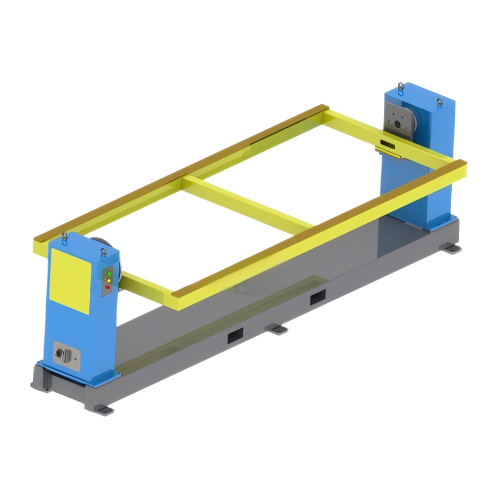

Högpresterande enaxlig positionerare för huvud-/dubbdocka för robotsvetssystem (800 kg/1000 kg kapacitet)

Som en ledande tillverkare specialiserad på arbetsstationer för integration av industriella robotsystem och robotbaserad kringutrustning, presenterar vi stolt vår premium enaxlig spindeldocka/dubbdocka svetspositionerare med en lastkapacitet på 800 kg/1000 kg. Detta svetsrobotpositionerare representerar det perfekta äktenskapet Tyskkonstruerad precision och Kinesisk tillverkningseffektivitet, vilket ger exceptionell prestanda till konkurrenskraftiga priser.

Vår 800 kg svetslägesställare är specifikt utformad för att integreras sömlöst med alla större svetsrobotarbetsstationer, inklusive system från Fanuc, KUKA, ABB och Yaskawa. Den robusta konstruktionen och det avancerade servostyrningssystemet gör den idealisk för krävande applikationer inom fordonstillverkning, tillverkning av tung utrustning, produktion av tryckkärl och svetsning av flyg- och rymdkomponenter.

Tekniska specifikationer och viktiga funktioner

1. Oöverträffad lastkapacitet och stabilitet

800 kg standardmodell (anpassningsbar till 1000 kg)

Kraftig stålkonstruktion med förstärkt ribbad design

Precisionsbearbetat roterande bord (Ø600 mm standard, anpassningsbar)

Dynamiskt balanseringssystem garanterar vibrationsfri drift

2. Avancerat rörelsekontrollsystem

AC-servomotordrift (5 kW standard)

Planetväxelreducerare (förhållande 1:50)

Positioneringsnoggrannhet±0,05°

Rotationshastighet: 0,1–2,5 varv/min (programmerbar)

360° kontinuerlig rotation med obegränsad positionering

3. Intelligenta integrationsfunktioner

Standard PROFINET/DeviceNet/EtherCAT-gränssnitt

Sömlös synkronisering med svetsrobotar

Positionsåterkoppling i realtid till robotstyrenheten

Automatisk kollisionsdetektering system

4. Förbättrade säkerhetsfunktioner

Elektromagnetisk broms för omedelbar stopp

Överbelastningsskydd med momentövervakning

Nödstoppkrets (dubbelkanalig)

IP54-skyddsklassning för tuffa miljöer

Varför välja vår svetspositionerare?

1. Överlägsen teknik och tillverkning

Varje 800 kg svetslägesställare genomgår:

FEA-optimerad strukturdesign

Precisions-CNC-bearbetning av kritiska komponenter

Laserjustering under montering

72 timmars kontinuerlig drifttestning

2. Anpassningsalternativ

Vi erbjuder flexibel anpassning:

Speciella bordsdiametrar (upp till Ø1200 mm)

Anpassade klämfästen

Explosionssäkra versioner för speciella miljöer

Färger som matchar din produktionslinje

3. Kostnadseffektiv automatiseringslösning

Jämfört med europeiska alternativ:

40% lägre pris med jämförbar kvalitet

50 dagars standardleverans (snabbare än branschgenomsnittet)

Lokal servicesupport på större marknader

Tillämpningar inom modern tillverkning

Vår svetsrobotpositionerare utmärker sig i olika tillämpningar:

1. Svetsning av fordonskomponenter

Chassirammontering

Tillverkning av avgassystem

Svetsning av upphängningskomponenter

2. Tillverkning av tung utrustning

Ramar för byggmaskiner

Jordbruksutrustningsstrukturer

Komponenter för gruvfordon

3. Tillverkning av tryckkärl

Tankens omkretssvetsning

Rörflänsmontering

Tillverkning av pannkomponenter

4. Flyg- och rymdtillämpningar

Flygplansstrukturelement

Motorfästen

Komponenter för landningsställ

Integrering med svetsrobotarbetsstation

Vår positionerare är utformad för perfekt harmoni med svetsrobotarbetsstationer:

Mekanisk integration

Standardiserade monteringsgränssnitt

Optimerad arbetshöjd (800 mm justerbar)

Ergonomisk arbetsyta

Elektrisk integration

Förkonfigurerade robotgränssnitt

Plug-and-play-kabelsystem

Enhetlig kontrollplattform

Processintegration

Synkroniserad svetsparameterkontroll

Automatisk positionssekvensering

Möjlighet till registrering av svetsdata

Kvalitetssäkring och certifieringar

ISO 9001:2015-certifierad tillverkning

CE-certifiering för europeiska marknader

UL-certifiering tillgänglig på begäran

12 månaders garanti med livstidsstöd

Konkurrensfördelar

1. Teknisk överlägsenhet

Högre styvhet än jämförbara modeller

Lägre energiförbrukning (20% mindre än konkurrenterna)

Längre livslängd (50 000+ timmar MTBF)

2. Service av högsta kvalitet

Globalt tekniskt supportnätverk

Online fjärrdiagnostik

48-timmars svarsgaranti

Lokalt reservdelslager

3. Smart tillverkningsklar

IIoT-anslutning för Industri 4.0

Förutsägande underhåll förmåga

Integrering av produktionsdata med MES

Slutsats: Det smarta valet för automatiserad svetsning

Vår enaxlig spindel-/dubbdockspositionerare representerar optimal lösning för tillverkare som vill förbättra sina arbetsstationer för svetsrobotar med pålitlig, högpresterande positioneringsutrustning. Med 800 kg/1000 kg lastkapacitet, subgradig noggrannhetoch sömlös robotintegration, denna lägesställare levererar:

30% ökning av svetsproduktiviteten

50% minskning av positioneringsfel

20% förbättring av svetskvaliteten

60% lägre total ägandekostnad

Kontakta vårt ingenjörsteam idag att diskutera hur vår svetsrobotpositionerare kan omvandla din produktion

SHENCHI ROBOT CO.,LTD erbjuder olika industrirobotar med automationslösningar. Vi stöder industrirobotar inklusive svetsning, målning, hantering, palletering, bockning och polering, välkommen att kontakta oss.

Shenchi-robot, smartare och enklare

© Shenchi Company Alla rättigheter förbehållna.