- เหวินหลิงเจ้อเจียงประเทศจีน

- [email protected]

- +86 18958695512

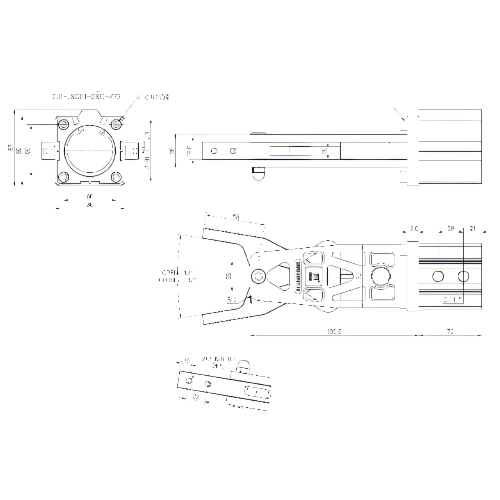

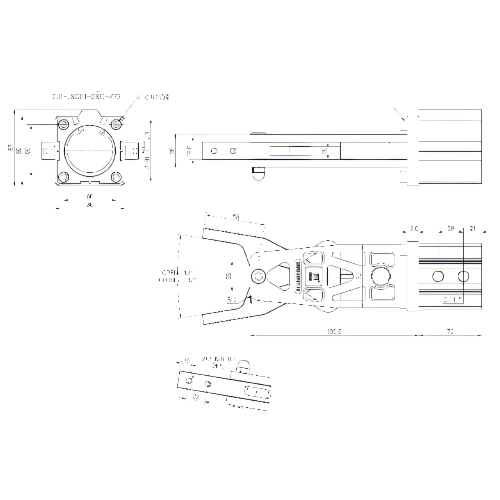

ขากรรไกรหนีบ ทนอุณหภูมิสูง กริปเปอร์หุ่นยนต์ที่ดีที่สุด

ในขณะที่ระบบอัตโนมัติทางอุตสาหกรรมยังคงพัฒนาอย่างต่อเนื่อง โซลูชันการจับยึดที่เชื่อถือได้จึงเป็นสิ่งจำเป็นสำหรับแขนหุ่นยนต์และระบบอัตโนมัติ โรงงานของเรามีความเชี่ยวชาญด้านการผลิต ขากรรไกรหนีบ — ส่วนประกอบสำคัญที่ช่วยให้มั่นใจถึงการจับที่มั่นคงและแม่นยำระหว่างการจัดการอัตโนมัติ โดยมุ่งเน้นที่ คุณภาพ ความคุ้มราคา และการปรับแต่ง, เราได้กลายเป็นซัพพลายเออร์ที่เชื่อถือได้ของ ขากรรไกรหนีบ, กริปเปอร์แบบยืดหยุ่น, กริปเปอร์ทนอุณหภูมิสูง และกริปเปอร์แบบกรงเล็บสองอัน ให้กับผู้ซื้อทั่วโลก

กริปเปอร์แบบยืดหยุ่น:ผลิตจากวัสดุที่สามารถปรับให้จับสิ่งของที่บอบบางหรือมีรูปร่างไม่สม่ำเสมอได้โดยไม่เกิดความเสียหาย เหมาะสำหรับอุตสาหกรรมอาหาร อุปกรณ์อิเล็กทรอนิกส์ และการแพทย์

กริปเปอร์ทนอุณหภูมิสูง:สร้างขึ้นเพื่อทนต่ออุณหภูมิได้สูงถึง 600°C เหมาะสำหรับการหล่อแบบฉีด การตีขึ้นรูป และการทำงานที่ต้องใช้ความร้อนสูงอื่นๆ

กริปเปอร์สองกรงเล็บ:การออกแบบคลาสสิกและทนทานสำหรับระบบอัตโนมัติทั่วไป ด้วยแรงยึดเกาะที่สูงและความแม่นยำที่เป็นเลิศ

SC-JJ008

จีน

30 วัน

ที/ที

หนิงโป/เซี่ยงไฮ้ จีน

ขากรรไกรจับยึดคุณภาพสูงสำหรับระบบอัตโนมัติในอุตสาหกรรม – ผู้ผลิตที่คุณไว้วางใจได้ในประเทศจีน

ในภูมิทัศน์ของระบบอัตโนมัติทางอุตสาหกรรมที่เปลี่ยนแปลงอยู่ตลอดเวลา ความแม่นยำ ประสิทธิภาพ และความสามารถในการปรับตัวเป็นสิ่งสำคัญอย่างยิ่งต่อความสำเร็จในการผลิต หัวใจสำคัญของระบบการจัดการแบบหุ่นยนต์และเครื่องกลจำนวนมากคือองค์ประกอบที่กำหนดวิธีการจับ ยึด และจัดการวัสดุ — ขากรรไกรหนีบในฐานะผู้ผลิตอุปกรณ์จับยึดหุ่นยนต์และชิ้นส่วนการยึดเชิงกลที่ทุ่มเทและมีประสบการณ์ โรงงานของเรามีความเชี่ยวชาญในการผลิต ขากรรไกรหนีบ สำหรับหลากหลายอุตสาหกรรม

จาก กริปเปอร์แบบยืดหยุ่น สำหรับส่วนประกอบที่ละเอียดอ่อน กริปเปอร์ทนอุณหภูมิสูง สำหรับสภาพแวดล้อมที่รุนแรงและ กรงเล็บสองอัน สำหรับการจับยึดที่แม่นยำ ขากรรไกรจับยึดของเราได้รับความไว้วางใจจากผู้ซื้อทั่วโลก ความน่าเชื่อถือ ราคาที่แข่งขันได้ และวิศวกรรมมืออาชีพหากคุณกำลังมองหาโซลูชันการยึดคุณภาพสูงสำหรับแขนหุ่นยนต์หรือระบบอัตโนมัติ เราคือผู้ผลิตที่คุณสามารถไว้วางใจได้

ขากรรไกรหนีบคืออะไร?

ขากรรไกรหนีบ เป็นส่วนประกอบทางกลที่ออกแบบมาเพื่อจับ ยึด หรือตรึงชิ้นงานให้อยู่ในตำแหน่งระหว่างการกลึง การประกอบ หรือการจัดการด้วยหุ่นยนต์ มักใช้ใน หุ่นยนต์ปลายแขน, เครื่อง CNC, แขนหยิบและวาง, และ สายการผลิตอัตโนมัติขากรรไกรจับมีรูปร่างและวัสดุหลากหลายขึ้นอยู่กับข้อกำหนดในการจับ

ขากรรไกรจับของเราได้รับการออกแบบมาให้มีความทนทานและแม่นยำ เพื่อให้แน่ใจว่า ประสิทธิภาพที่สม่ำเสมอ, ความสามารถในการทำซ้ำได้, และ การบำรุงรักษาขั้นต่ำ ในสภาพแวดล้อมการผลิตปริมาณสูง

ประเภทของขากรรไกรหนีบที่เรานำเสนอ

เรามีขากรรไกรจับยึดหลากหลายรุ่นให้เลือกสรร ออกแบบมาเพื่อตอบสนองความต้องการเฉพาะของระบบอัตโนมัติหุ่นยนต์และการจับยึดในอุตสาหกรรม รุ่นยอดนิยมของเราประกอบด้วย:

1. ขากรรไกรจับแบบยืดหยุ่น

ออกแบบมาสำหรับชิ้นงานที่อ่อน เปราะบาง หรือมีรูปร่างไม่สม่ำเสมอ กริปเปอร์แบบยืดหยุ่น โดดเด่นด้วยวัสดุที่ปรับเปลี่ยนได้และโครงสร้างขากรรไกรที่สอดคล้องกับรูปทรงต่างๆ โดยไม่ทำให้ผลิตภัณฑ์เสียหาย ขากรรไกรเหล่านี้เหมาะอย่างยิ่งสำหรับ:

การประกอบชิ้นส่วนอิเล็กทรอนิกส์

บรรจุภัณฑ์อาหาร

การจัดการอุปกรณ์ทางการแพทย์

การถ่ายโอนชิ้นส่วนที่เปราะบาง

ของเรา ขากรรไกรหนีบแบบยืดหยุ่น ให้ความไวและความสามารถในการปรับได้สูง ช่วยให้จับได้นุ่มนวลแต่มั่นคงโดยไม่กระทบความแม่นยำ

2. ขากรรไกรจับยึดที่ทนต่ออุณหภูมิสูง

สำหรับการใช้งานเช่น การตีโลหะ, การหล่อแบบตายตัว, การจัดการเครื่องยนต์ยานยนต์, และ การดำเนินการอบชุบด้วยความร้อน, ของเรา กริปเปอร์ทนอุณหภูมิสูง ผลิตจากวัสดุขั้นสูงที่ทนต่ออุณหภูมิที่รุนแรง

ทนความร้อน: สูงสุด 400–600°C

วัสดุ: สแตนเลสผ่านการอบด้วยความร้อน, เซรามิก, โลหะผสมพิเศษ

เสถียรภาพทางกลและความต้านทานความล้าจากความร้อนที่ยอดเยี่ยม

ขากรรไกรเหล่านี้เหมาะอย่างยิ่งสำหรับแขนหุ่นยนต์ที่ทำงานในโรงงานที่มีอุณหภูมิสูงซึ่งต้องไม่กระทบต่อประสิทธิภาพและความปลอดภัย

3. ขากรรไกรจับสองกรงเล็บ

การ กริปเปอร์สองกรงเล็บ เป็นการออกแบบกริปเปอร์หุ่นยนต์แบบคลาสสิกและอเนกประสงค์สูง โดดเด่นในเรื่องความเรียบง่ายและความทนทาน ขากรรไกรจับสองกรงเล็บ เสนอ:

ความสามารถในการทำซ้ำได้สูง

แรงยึดเกาะที่สมดุล

การบำรุงรักษาง่าย

โครงสร้างที่กะทัดรัด

ขากรรไกรเหล่านี้ใช้กันอย่างแพร่หลายใน ระบบอัตโนมัติเอนกประสงค์, การกลึง, และ สายการประกอบมีให้เลือกทั้งแบบขนานและแบบเหลี่ยม ปรับให้เหมาะกับการใช้งานในการจับที่หลากหลาย

เหตุใดจึงควรเลือกขากรรไกรหนีบของเรา?

ในฐานะผู้ผลิตเฉพาะทางที่มีฐานอยู่ในประเทศจีน เรานำ ประสบการณ์หลายทศวรรษ, สายการผลิต CNC ที่ทันสมัย, และ การควบคุมคุณภาพอย่างเข้มงวด เข้าไปในชุดจับยึดทุกชุดที่เราผลิต นี่คือเหตุผลที่ผู้ซื้อทั่วโลกเลือกเรา:

1. ราคาตรงจากโรงงาน

โดยการกำจัดคนกลาง เราจึงเสนอ ราคาที่มีการแข่งขันสูง สำหรับผลิตภัณฑ์ทั้งหมดของเรา ไม่ว่าคุณจะเป็น OEM ผู้จัดจำหน่าย หรือผู้ติดตั้งอุปกรณ์ คุณก็สามารถเพิ่มมูลค่าสูงสุดได้ในขณะที่ยังคงรักษาคุณภาพไว้ได้

2. วัสดุคุณภาพพรีเมี่ยม

ขากรรไกรทั้งหมดทำจาก เหล็กชุบแข็ง โลหะผสมอลูมิเนียม พลาสติกวิศวกรรม หรือวัสดุที่กำหนดเอง ตามความต้องการของลูกค้า กระบวนการอบชุบด้วยความร้อนและการตกแต่งพื้นผิวขั้นสูงของเรารับประกันคุณภาพที่เหนือกว่า:

ความต้านทานการสึกหรอ

ความจุในการรับน้ำหนัก

อายุยืนยาว

3. สามารถปรับแต่งได้

ต้องการขนาด รูปทรง หรือฟังก์ชันพิเศษหรือไม่? เรามีบริการ โออีเอ็ม และ โอดีเอ็ม บริการผลิตขากรรไกรจับยึดตามแบบหรือตัวอย่างของคุณ ทีมวิศวกรของเราทำงานอย่างใกล้ชิดกับคุณเพื่อให้มั่นใจว่าได้ชิ้นงานที่พอดีและประสิทธิภาพการทำงานที่แม่นยำ

4. ความสามารถในการผลิตจำนวนมาก

ด้วยของเรา สายการผลิตอัตโนมัติ, ศูนย์เครื่องจักรกลซีเอ็นซีหลายแกน, และ ระบบการผลิตแบบลีนที่เข้มงวด, เรามีความสามารถในการจัดการ คำสั่งซื้อจำนวนมากพร้อมการดำเนินการที่รวดเร็ว.

ผลผลิตต่อวัน: สูงสุด 10,000 หน่วย

ระยะเวลาดำเนินการ: 7–15 วัน ขึ้นอยู่กับขนาดของคำสั่งซื้อ

มีบริการจัดส่งทั่วโลก

5. ได้รับความไว้วางใจจากผู้ซื้อหลายพันราย

ขากรรไกรหนีบของเราใช้ใน ยุโรป อเมริกาเหนือ เอเชียตะวันออกเฉียงใต้ และตะวันออกกลาง ข้ามอุตสาหกรรม เช่น:

หุ่นยนต์และระบบอัตโนมัติ

การผลิตยานยนต์

การกลึง CNC

บรรจุภัณฑ์และโลจิสติกส์

การบินและอวกาศและอิเล็กทรอนิกส์

ในแต่ละปีเราให้บริการ ผู้ซื้อต่างชาติหลายพันรายซึ่งหลายรายเป็นพันธมิตรระยะยาวที่ไว้วางใจในคุณภาพที่มั่นคงและการส่งมอบตรงเวลาของเรา

SHENCHI ROBOT CO.,LTD จัดจำหน่ายหุ่นยนต์อุตสาหกรรมต่างๆ พร้อมโซลูชันอัตโนมัติ เรารองรับหุ่นยนต์อุตสาหกรรมต่างๆ รวมถึงงานเชื่อม การทาสี การจัดการ การจัดวางบนพาเลท การดัด และการขัดเงา ยินดีต้อนรับติดต่อเรา

หุ่นยนต์ Shenchi ฉลาดขึ้น เรียบง่ายขึ้น

© บริษัท Shenchi สงวนลิขสิทธิ์