- Wenling zhejiang Çin

- [email protected]

- +86 18958695512

- Ev

- ÜRÜNLER

- ENDÜSTRİYEL ROBOT

- DİĞER UYGULAMALAR ROBOT

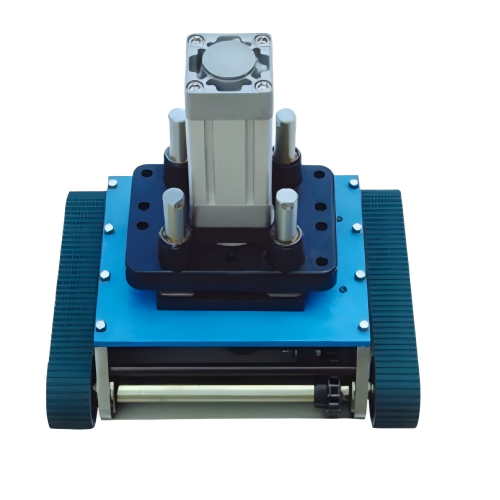

- yük taşıma endüstriyel robotu en iyi Montaj Damgalama robotu

Yük taşıma endüstriyel robotu en iyi Montaj Damgalama robotu

biz uzmanlaştık yük taşıma endüstriyel robotları optimize etmek için tasarlandı malzeme taşımacılığı, paletleme ve makine bakımı modern fabrikalarda. Yükümüz endüstriyel robotların kullanımı birleştirmek Alman mühendislik hassasiyeti ve rekabetçi Çin üretim maliyetleri, teslim etmek yüksek yük kapasitesi (50-2.000 kg), hızlı çevrim süreleri ve güvenilir performans Uygun fiyata.

Temel Özellikler:

Ağır Hizmet Tipi İnşaat – Güçlendirilmiş çelik çerçeve ile IP67 koruması

Hassas Kullanım – ±0,05 mm tekrarlanabilirlik doğru yerleştirme için

Yüksek Hız – Kadar 2,5 m/sn maksimum verimlilik için

Akıllı Kontrol – PLC/HMI arayüzü, IoT'ye hazır

SC-CH2100

ÇİN

30 GÜN

T/T

NINGBO/ŞANGAY ÇİN

Yüksek Performanslı Yük Taşıma Endüstriyel Robotları – Güvenilir Otomasyon Ortağınız

biz uzmanlaştık yük taşıma endüstriyel robotları Modern üretim tesislerinde malzeme taşımacılığında devrim yaratacak şekilde tasarlanmıştır. taşıma robotları birleştirmek Alman mühendislik hassasiyeti ve rekabetçi Çin üretim maliyetleri, teslim etmek eşsiz yük kapasitesi, operasyonel verimlilik ve güvenilirlik Dünya çapındaki fabrikalar için.

İle 15 yılı aşkın sektör deneyimi ve birçok başarılı kurulumlar, bizim yük taşıma endüstriyel robotları üreticilere yardımcı olmak otomotiv, lojistik, metal işleme ve elektronik endüstrileri ile:

İşçilik maliyetlerini azaltın 60%'ye kadar

Üretkenliği artırın 30-50% tarafından

İşyeri güvenliğini iyileştirin

Zemin alanı kullanımını optimize edin

Neden Yük Taşıma Endüstriyel Robotlarımızı Seçmelisiniz?

1. Üstün Yük ve Performans

Ağır hizmet tipi modeller (50kg – 2.000kg kapasite)

Yüksek hızlı çalışma (2,5 m/s'ye kadar)

±0,05 mm tekrarlanabilirlik hassas kullanım için

Gelişmiş servo kontrolü pürüzsüz hareket için

2. Sağlam Endüstriyel Yapı

Güçlendirilmiş çelik/alüminyum çerçeve

IP67 koruması (toz geçirmez ve su geçirmez)

50.000 saatlik MTBF (Arızalar Arası Ortalama Süre)

Aşırı yük ve çarpışma algılama

3. Akıllı Otomasyon Özellikleri

PLC ve HMI kontrol entegrasyonu

Görüntü yönlendirmeli toplama sistemleri

Endüstri 4.0 için IoT'ye hazır

Çoklu robot senkronizasyonu

4. Maliyet Etkin Avantajlar

30-50% daha uygun fiyatlı Avrupa markalarından daha fazla

60 günlük standart teslimat

Düşük enerji tüketimi

Kolay bakım tasarımı

Temel Uygulamalar

1. Otomotiv Üretimi

Gövde paneli kullanımı

Motor bileşeni transferi

Montaj hattı beslemesi

2. Lojistik ve Depolama

Paletleme/paletten çıkarma

AGV yükleme/boşaltma

Konteyner paketleme

3. Metal Üretimi

CNC makine bakımı

Pres freni çalışması

Dökümhane uygulamaları

4. Elektronik Üretimi

PCB kullanımı

Ekran paneli transferi

Hassas bileşen montajı

Yük taşıma endüstriyel robotlarının rekabet avantajları

Daha yüksek yük-ağırlık oranı rakiplerinden daha fazla

Daha hızlı hızlanma/yavaşlama

Daha düşük güç tüketimi

Daha basit entegrasyon mevcut sistemlerle

Küresel Alıcılar Neden Bize Güveniyor?

ISO 9001 ve CE Sertifikalı Üretim

5 Yıllık Garanti kritik bileşenlerde

7/24 Teknik Destek

Yerel Hizmet Ortakları 12 ülkede

Özelleştirme Seçenekleri

Sunduğumuz hizmetler:

Özel son efektörler (tutucu, vakumlu kaplar)

Özel erişim yapılandırmaları

Temiz oda uyumlu modeller

Patlamaya dayanıklı versiyonlar

Başarı Hikayeleri

Vaka Çalışması 1: Avrupalı otomobil parçaları tedarikçisi, yıllık elleçleme maliyetlerini 350.000 avro azaltırken, üretim kapasitesini 45% artırdı.

Vaka Çalışması 2: Asyalı elektronik üreticisi, görüntü yönlendirmeli robotlarımızla ,5% kullanım doğruluğuna ulaştı.

Malzeme Taşımacılığınızı Bugün Geliştirin!

Bizim yük taşıma endüstriyel robotları teslim etmek:

Profesyonel düzeyde performans

Hızlı ROI (genellikle <12 ay)

Geleceğe Hazır Otomasyon Yük Taşıma Endüstriyel Robotu, üretim, depolama ve lojistik operasyonlarında ağır veya hacimli ürünleri kaldırmak, taşımak ve konumlandırmak için tasarlanmış otomatik bir robotik sistemdir. Bu robotlar, malzeme taşıma görevlerinde manuel işçiliğin yerini alacak, verimliliği, hassasiyeti ve iş yeri güvenliğini artıracak şekilde tasarlanmıştır.

Bu Robotları Kim Kullanıyor?

• Otomotiv Üreticileri (motor/gövde parçası kullanımı)

• Depolar ve Lojistik Merkezleri (paletleme/sıralama)

• Metal ve Plastik Üreticileri (CNC makine bakımı)

• Gıda ve İlaç (hijyenik malzeme transferi)Temel Özellikler ve Yetenekler:

Yüksek Yük Kapasitesi – Ağırlıkları tutar 50kg ile 2.000kg+ arası

Hassas Hareket – ±0,05 mm ila ±0,2 mm tekrarlanabilirlik doğru yerleştirme için

Esnek Otomasyon – İçin kullanılır paletleme, makine bakımı, montaj ve daha fazlası

Akıllı Entegrasyon – İle çalışır PLC'ler, AGV'ler ve IoT özellikli sistemler

SHENCHI ROBOT CO.,LTD otomasyon çözümleriyle farklı endüstriyel robotlar sağlar. Kaynak, boyama, taşıma, paletleme, bükme ve parlatma dahil olmak üzere endüstriyel robotları destekliyoruz, bizimle iletişime geçmekten memnuniyet duyarız.

Shenchi robotu, Daha akıllı, daha basit

© Shenchi Şirketi Tüm hakları saklıdır.