- Wenling zhejiang China

- [email protected]

- +86 18958695512

- Home

- PRODUCTS

- INDUSTRIAL ROBOT

- PALLETIZING ROBOT

- Wingspan Palletizing Robot best 7kg industrial robot hotsell

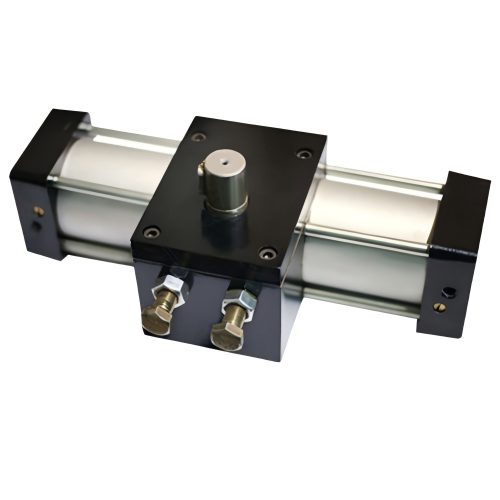

Wingspan Palletizing Robot best 7kg industrial robot hotsell

we proudly introduce our Wingspan Palletizing Robot – a lightweight, space-saving, and high-speed automation solution designed for assembly, sorting, handling, and loading/unloading applications. With its compact architecture, large workspace, and ±0.02mm repeatability, this 7kg industrial robot delivers precision, efficiency, and affordability, making it ideal for SMEs and large-scale manufacturers.

Applications:

Palletizing & Depalletizing (boxes, cartons, bags)

Machine Tending (CNC, injection molding)

Assembly & Sorting (electronics, small parts)

Collaborative Workspaces (safe near workers)

SC-7-900

CHINA

30DAYS

T/T

NINGBO/SHANGHAI CHINA

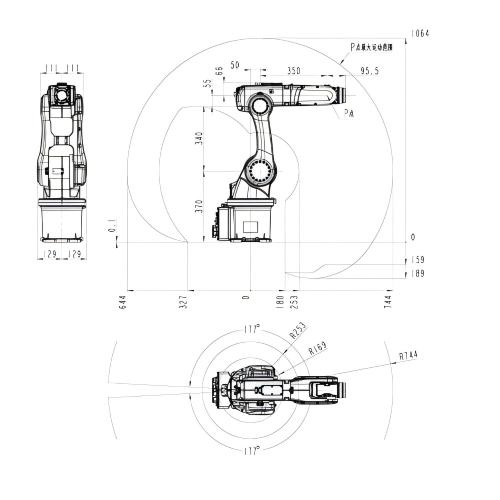

| Degree of freedom | 6 | ||

| Payload | 7kg | ||

| Wingspan | 903.5mm | ||

| Repeatability^2 | ±0.02mm |

Wingspan Palletizing Robot – Compact, Efficient & Cost-Effective Automation Solution

Wingspan Palletizing Robot is a compact, high-speed industrial robot specifically designed for automated palletizing, sorting, and material handling in manufacturing and logistics. It features a lightweight yet durable structure, large workspace coverage, and high repeatability (±0.02mm), making it ideal for fast, precise loading/unloading, assembly, and packaging tasks.

we proudly introduce our Wingspan Palletizing Robot, a high-performance, lightweight, and space-saving automation solution designed for assembly, sorting, material handling, and loading/unloading applications. With its innovative compact architecture, large workspace, and rapid response time, this 7kg industrial robot delivers precision, speed, and reliability at an affordable price, making it ideal for small to medium-sized manufacturers.

Our Wingspan Palletizing Robot is engineered to reduce labor costs, enhance productivity, and improve workplace safety—trusted by 500+ global clients in industries such as logistics, food & beverage, pharmaceuticals, and electronics.

Why Choose Our Wingspan Palletizing Robot?

1. Compact & Lightweight Design

Space-saving footprint – Ideal for facilities with limited floor space

Lightweight yet durable – Aluminum alloy & high-strength composite materials

Easy integration – Fits seamlessly into existing production lines

2. Large Workspace & High Speed

Extended reach (1,200mm+) – Covers more work area than standard robots

Fast cycle times (0.5s/pick) – Boosts throughput by 30%+

±0.02mm repeatability – Ensures precise palletizing and sorting

3. Versatile Applications

Palletizing & Depalletizing – Boxes, bags, cartons (up to 7kg)

Assembly Line Handling – Small parts sorting and placement

Machine Tending – CNC, injection molding, and packaging machines

Collaborative Workspaces – Safe operation alongside workers

4. Smart Control & Energy Efficiency

PLC & HMI interface – Easy programming and operation

IoT-ready – Real-time monitoring and predictive maintenance

Low power consumption – 20% more efficient than competitors

Key Industries & Applications

1. Logistics & Warehousing

Automated box stacking for e-commerce fulfillment

AGV (Automated Guided Vehicle) integration

Order sorting & conveyor belt handling

2. Food & Beverage

Packaging of bottles, cans, and pouches

Sanitary-grade models available (IP67)

Quick changeover for different product sizes

3. Pharmaceuticals & Electronics

Precision component placement

Anti-static & cleanroom-compatible versions

Small-part sorting for assembly lines

4. General Manufacturing

Machine loading/unloading

Injection molding part removal

Light material transfer

Competitive Advantages

30% More Affordable – Lower cost than European/Japanese brands

Faster ROI – Payback period of under 12 months

Plug-and-Play Installation – Reduces setup time

Low Maintenance – Sealed joints & long-life components

Why Global Buyers Trust Us?

ISO 9001 & CE Certified Manufacturing

5,000+ Robots Installed Worldwide

24/7 Technical Support

3-Year Warranty on Motors & Controllers

Customization Options

We offer tailored solutions including:

Special end-effectors (grippers, suction cups)

Custom reach & payload configurations

Vision-guided picking systems

Branding & color customization

SHENCHI ROBOT CO.,LTD provide different industrial robot with automation solutions . we support industrial robots including welding, painting, handling, palletizing, bending and polishing, welcome to contact us.

Shenchi robot ,More smart more simple

© Shenchi Company All right reserved.